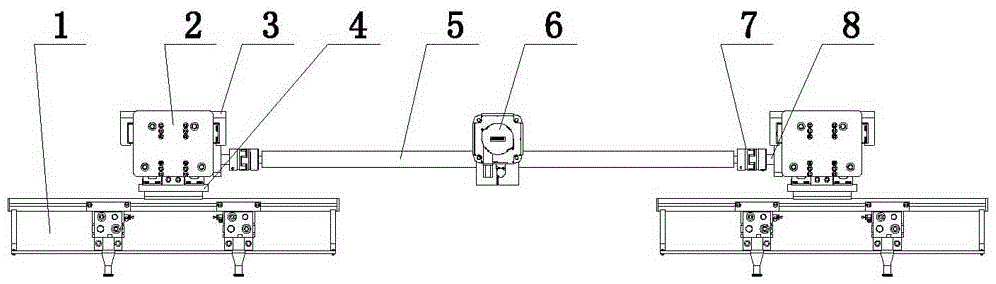

Double-speed telescopic double-drive locating system

A positioning system and double-speed technology, applied in positioning devices, manipulators, metal processing equipment, etc., can solve the problems that the load beam is difficult to meet the work requirements, takes a long time, and has low work efficiency, and achieves a perfect balance of diversity, beautiful appearance, The effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

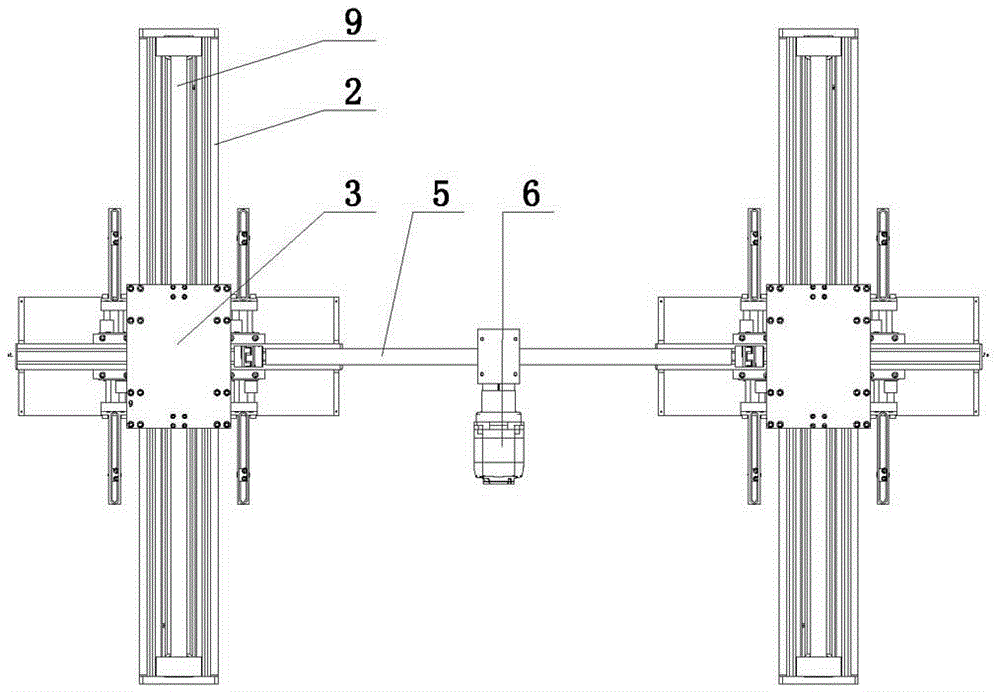

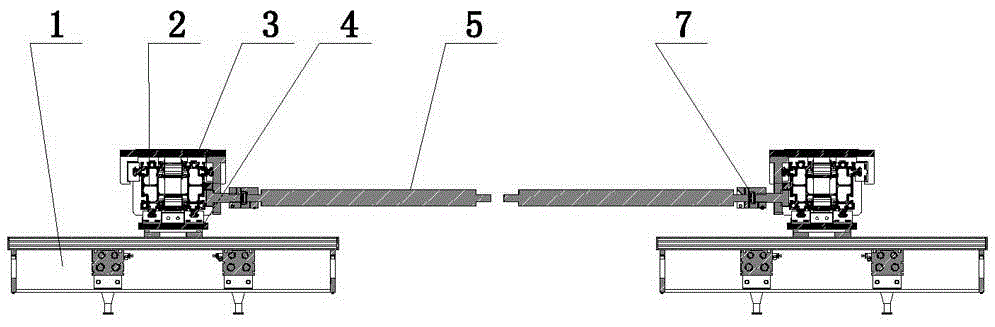

[0020] The present invention comprises two load-bearing beams 2, and is characterized in that: the side of two load-bearing beams 2 is provided with driving rack 11; Between two load-bearing beams 2, drive motor 6 is arranged, and the gears at both ends of synchronous shaft 5 on drive motor 6 12 respectively meshes with the racks 11 on the sides of the two load beams 2; the upper slide plate 3 is arranged above the load beam 2, and the upper slide plate 3 is connected with the synchronous shaft 5 through the connecting plate 10; A synchronous belt 9 is arranged, and the top of the synchronous belt 9 links to each other with the described upper slide plate 3;

[0021] As a preferred solution of the present invention, the connecting plate 10 is provided with a short shaft 8 , the gear 12 is provided at one end of the short shaft 8 , and the synchronous shaft 5 is connected with the short shaft 8 through a coupling 7 .

[0022] Upper guide rails 14 are arranged on both sides of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com