3D printing section matching method, composite forming method and section restoration method

A technology of 3D printing and matching method, applied in the field of 3D printing, can solve the problems of difficult to completely overlap the placement position, high cost of complex structural parts, poor cross-section matching accuracy, etc., so as to shorten the processing cycle, reduce the processing cost, and ensure the forming quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments, but the present invention is not limited to these embodiments.

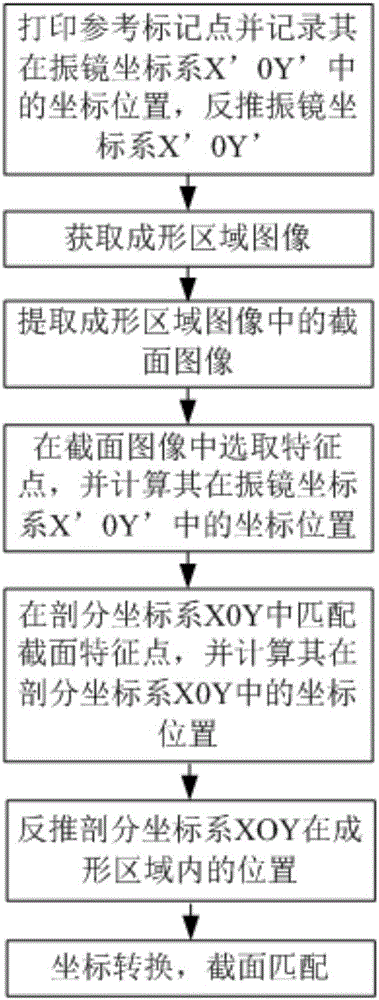

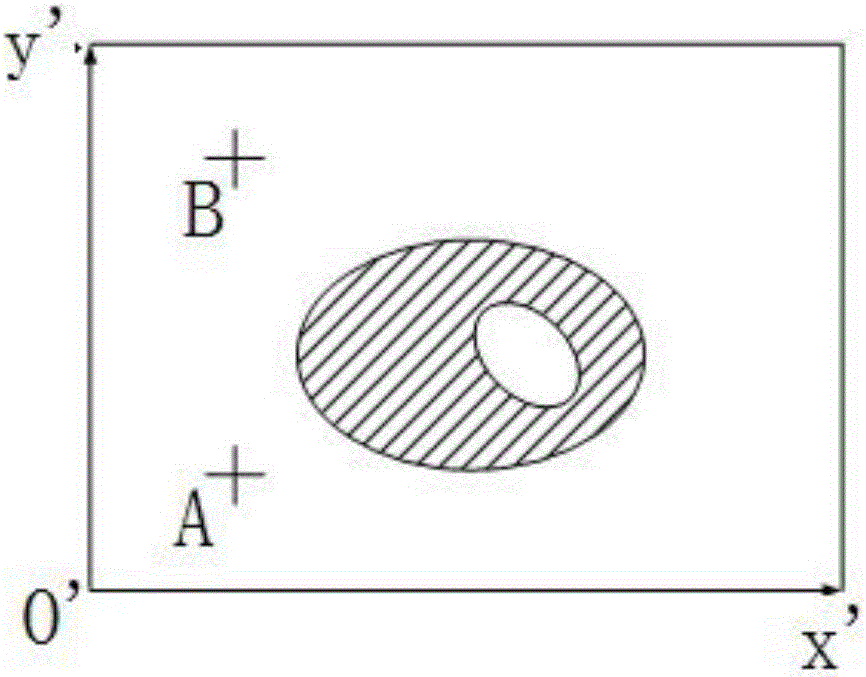

[0036] The 3D printing cross-section matching method of the present invention is proposed to match the cross-section of the part to be printed in 3D printing with the cross-section of the formed part, so that the subsequent printing can be accurately combined with the formed part.

[0037] The section matching method is suitable for a new 3D printing method proposed by the present invention, that is, a 3D printing composite forming method. The composite forming method includes: dividing the part into a basic part and a complex structural part, and firstly completing the basic part of the part by machining. The part is formed, and then the complex structure part is formed on the basic part of the part by 3D printing technology.

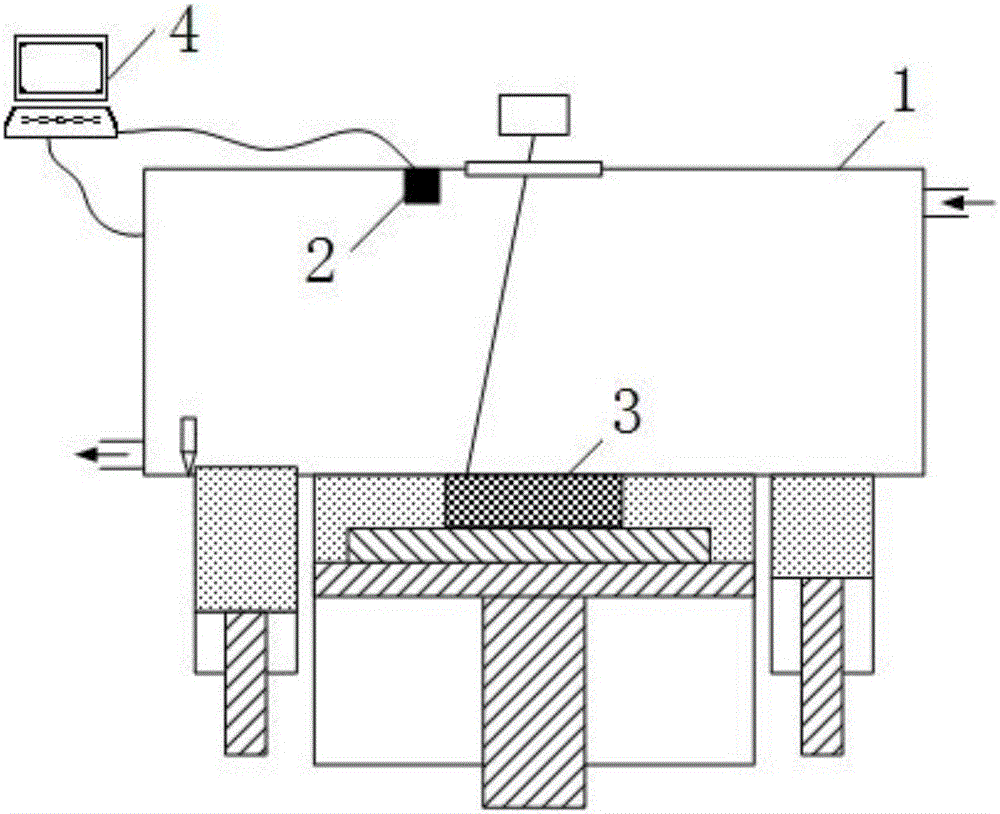

[0038] The 3D printing composite forming met...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com