Welding flux position adjusting device assisting in working of weldable testing instrument

A technology for adjusting devices and testers, applied in auxiliary devices, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problem that the pins cannot be directly aligned with the center of the solder ball, and achieve the effect of rapid adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

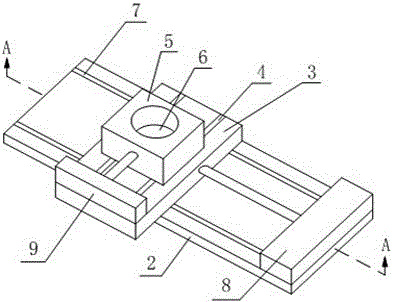

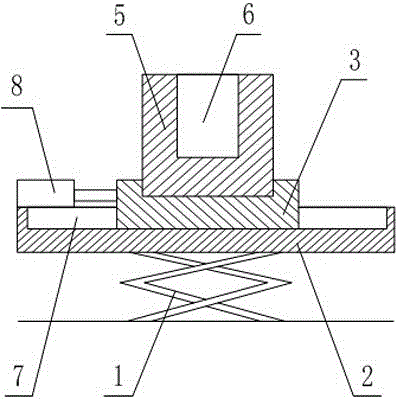

[0019] like figure 1 and figure 2 Shown is a solder position adjustment device 1 that assists the work of a solderability tester. The lifting device 1 is fixed with a rectangular first flat plate 2, and the upper surface of the first flat plate 2 is provided with a first A chute 7, the upper surface of the first flat plate 2 is provided with a first drive device 8 and a second flat plate 3 connected to the driving end of the first drive device 8, and the second flat plate 3 slides along the first chute 7; The upper surface of the second flat plate 3 is provided with a second chute 4, the second chute 4 is perpendicular to the first chute 7, the second flat plate 3 is provided with a second driving device 9, and is connected with the second driving device 9. The sliding block 5 connected, the sliding block 5 slides along the second chute 4, the surface of the sliding block 5 is provided with a solder groove 6; the first chute 7 has two parallel to each other; the second chute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com