Flat fillet welding trolley welding auxiliary device

An auxiliary device, flat fillet welding technology, applied in the direction of auxiliary devices, welding/cutting auxiliary equipment, welding equipment, etc., can solve the problem that the flat fillet welding trolley cannot be used to stop the collision, limit the promotion and use of more than one person, and cannot complete the weld seam welding and other issues to achieve the effect of increasing the quantity, avoiding secondary welding, and reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments, but the present invention is not limited to these embodiments.

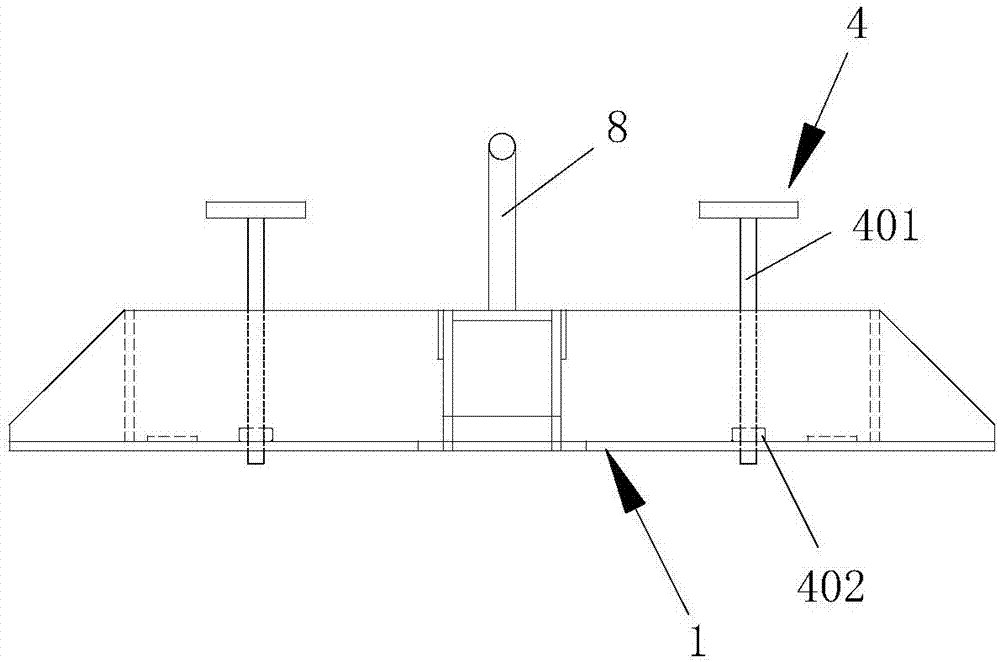

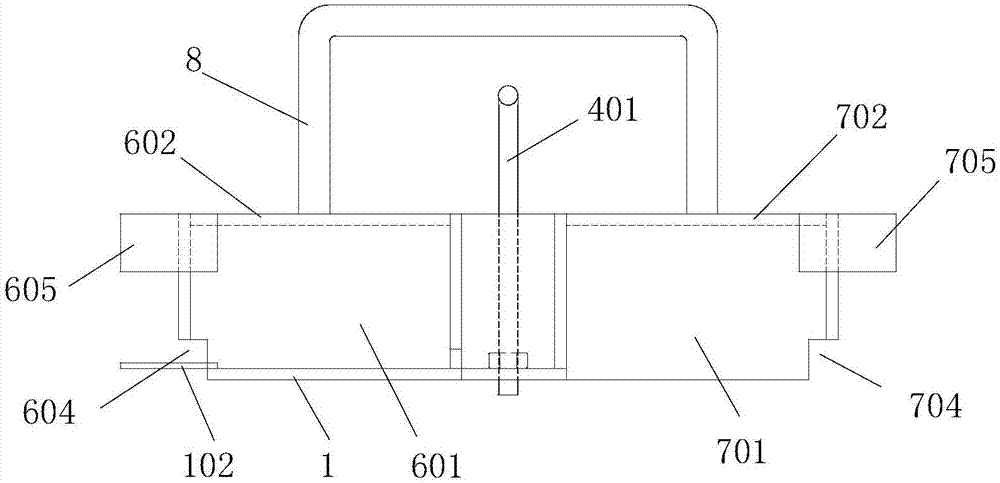

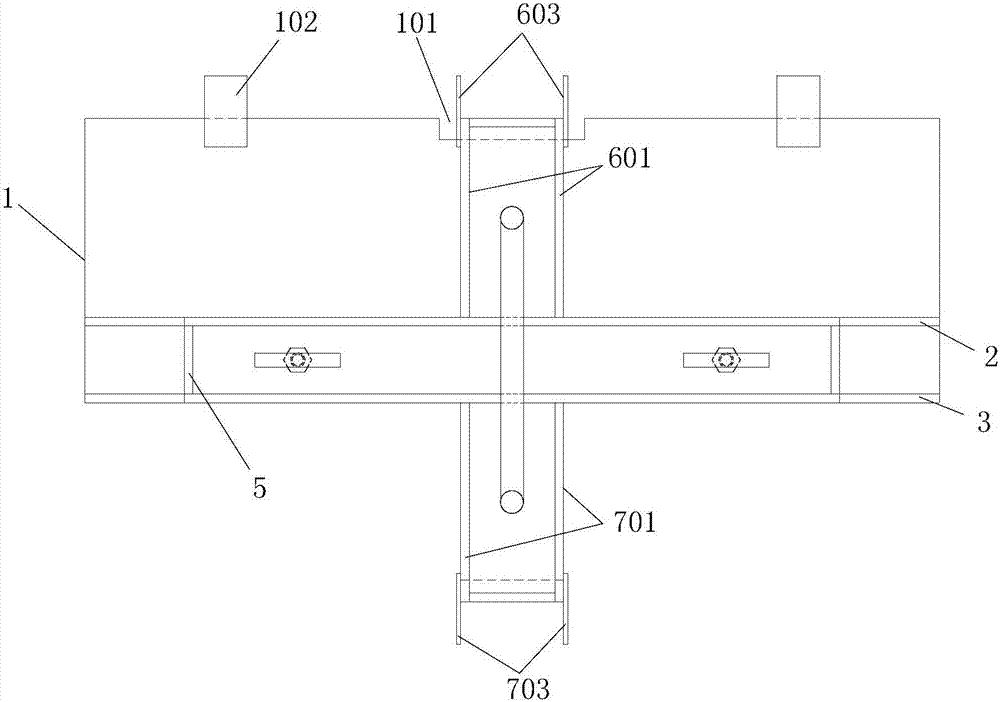

[0027] Such as Figure 1 to Figure 3 As shown, the welding auxiliary device of the flat fillet welding trolley includes a bottom plate 1, a collision plate and a U-shaped plate arranged on one side of the collision plate and connected to the collision plate. A second inner groove 101 is formed on the side of the bottom plate 1 that is in contact with the tire plate 10 of the steel plate to be welded. The arrangement of the second inner groove 101 forms a disconnection between the tire plate 10 and the bottom plate 1 , preventing welding fusion between the tire plate 10 and the bottom plate 1 during the welding process. Two second transition blocks 102 are provided on the side of the bottom plate 1 in contact with the tire plate 10 of the steel plate to be welded, which ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com