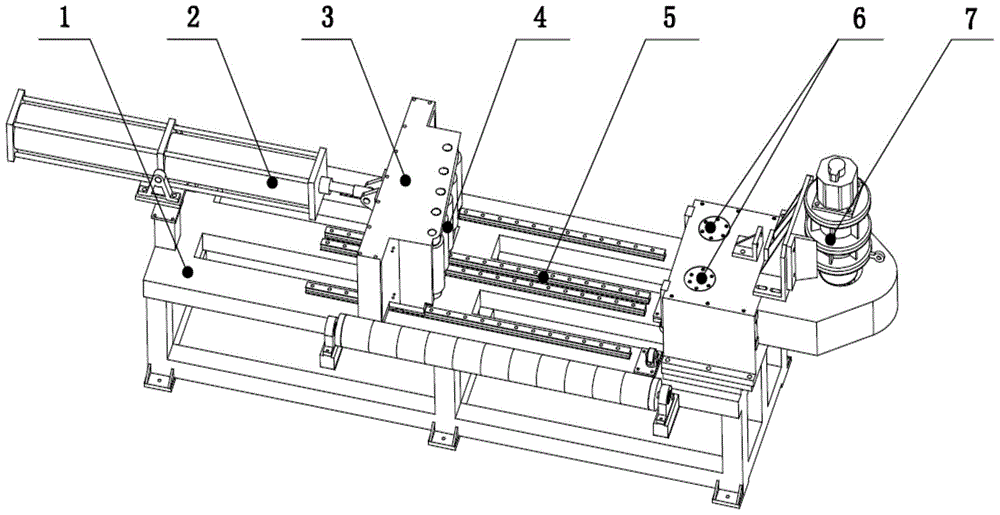

An H-shaped steel eccentric positioning clamping device

A technology for positioning and clamping, H-beam, applied in auxiliary devices, auxiliary welding equipment, welding/cutting auxiliary equipment, etc. Work intensity, the effect of improving process quality and production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

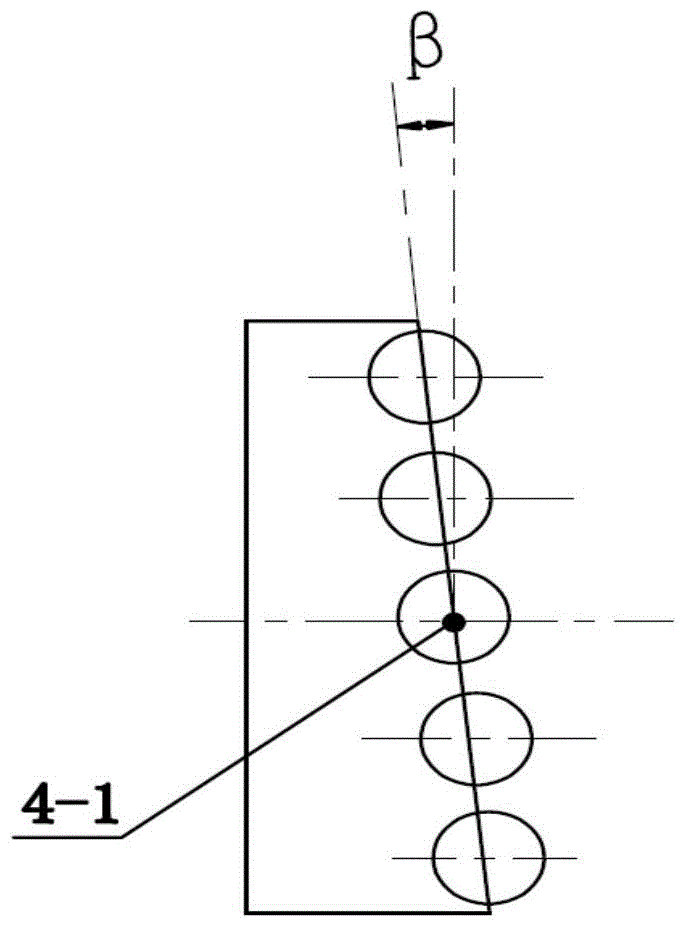

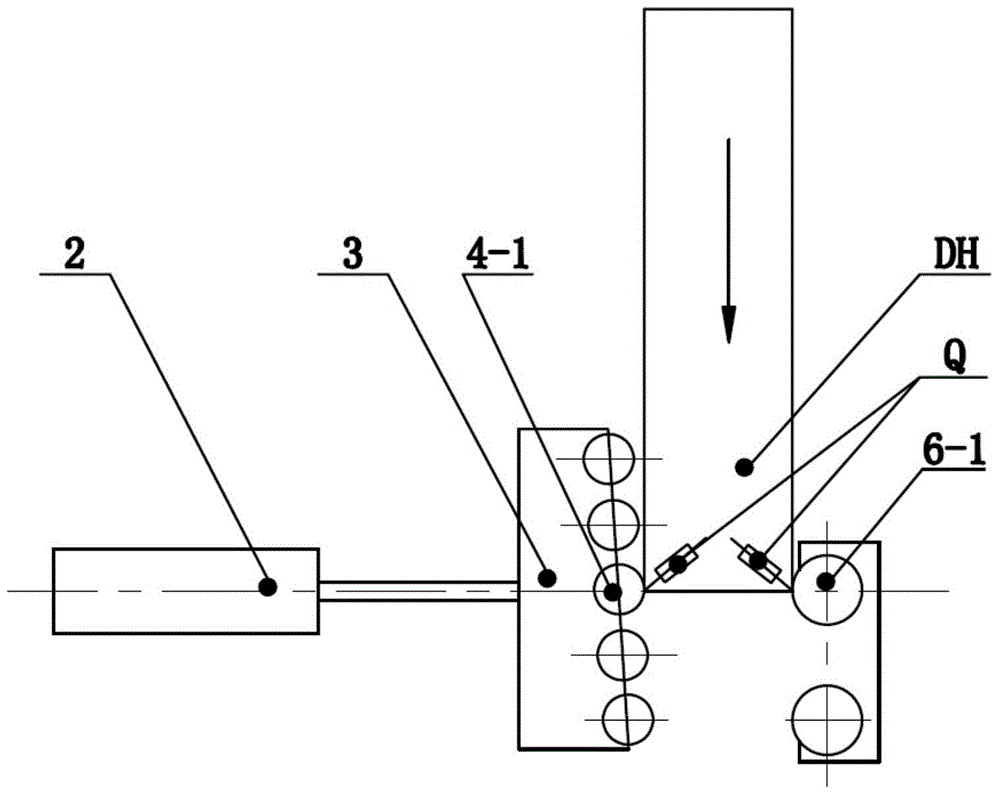

Embodiment 1

[0021] Embodiment 1. When the positioning and clamping device of the present invention is used for positioning and clamping of H-shaped steel with equal cross-section, since the present invention does not set a central rotating shaft, there is no problem of positioning failure caused by the overall rotation deviation of the clamping roller 4, DH The head end is delivered to such as image 3 In the position shown, the central roller shaft 4-1 of the eccentric clamping roller 4 and the driving wheel 6-1 arranged on the same centerline form two reliable positioning points, so the welding torch Q arranged above the corresponding welding seam is aligned with H Precise welding is carried out on the weld seams on both sides of the profile steel; when the workpiece is welded to the end such as Figure 4 In the position shown, although the central roller shaft 4-1 is separated from the tail end of the workpiece, there is still a reliable clamping of the clamping roller shaft and the wo...

Embodiment 2

[0022] Embodiment 2, when the positioning and clamping device of the present invention is used for the positioning and clamping of variable-section H-shaped steel, it effectively solves the reliable clamping and positioning of the head and end of the H-shaped steel, and the variable-section H-shaped steel BH head is transported to such as Figure 5 In the position shown, the central roller shaft 4-1 of the eccentric clamping roller 4 and the driving wheel 6-1 arranged on the same centerline form two reliable positioning points, so the welding torch Q arranged above the corresponding welding seam is aligned with H Precise welding is carried out on the weld seams on both sides of the profile steel; when the workpiece is welded to the end such as Figure 6 In the position shown, the central roller shaft 4-1 and the driving wheel 6-1 can still form two reliable positioning points, and after the welding torch Q closes the arc, the full welding process of the variable cross-section H...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com