Titanium alloy angular joint welding method based on double-beam laser

A welding method and double-beam technology, which are applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of low welding efficiency and large deformation of titanium alloy angle profiles, and achieve good process applicability, reduce welding deformation, The effect of improving welding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

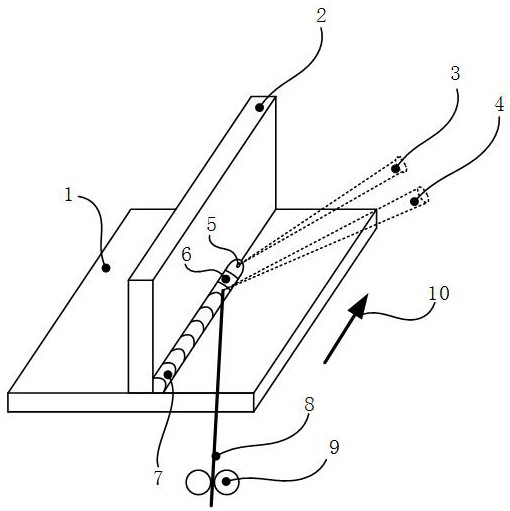

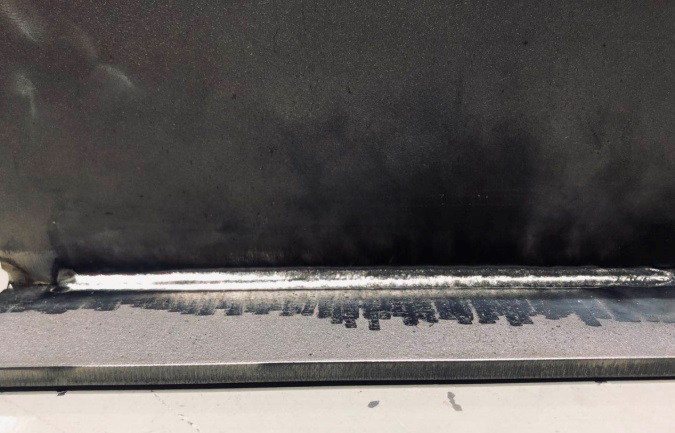

[0039] Such as figure 2 and image 3 As shown, the appearance of the titanium alloy T-shaped corner joint double-beam laser welding joint and the macro-section of the weld seam. Double-sided welding one-time penetration forming, welding process specification: front laser power 4500w, rear laser power 3000w, defocus +10mm, welding speed 72cm / min, wire feeding speed 3m / min, welding front and back shielding gas Both are 99.99% pure argon. The surface of the double-beam laser welding joint is beautiful, silver-white, and the transition of the fillet weld is smooth. There are no defects on the surface such as cracks, unfused, undercuts, arc craters, spatters, welding tumors, etc., and the surface quality is good; the macroscopic view of the double-beam laser welding joint is On the surface of the section, the weld fusion is good, and there are no cracks, pores, inclusions, incomplete fusion, incomplete penetration, poor shape and size and other defects inside, and the internal q...

Embodiment 2

[0041] Such as Figure 4 and Figure 5As shown, the appearance of the titanium alloy T-shaped corner joint double-beam laser welding joint and the macro-section of the weld seam, the face plate is 8mm, the web is 4mm, and the fillet welds on both sides are welded by double-beam laser wire filler respectively to realize the T-shaped corner The joint is double-sided welded for one penetration forming, and the welding process specification is selected: front laser power 5000w, rear laser power 3000w, defocus +10mm, welding speed 72cm / min, wire feeding speed 3m / min, welding front and back protection The gas is 99.99% pure argon. The surface of the double-beam laser welding joint is beautiful, silver-white, and the transition of the fillet weld is smooth. There are no defects on the surface such as cracks, unfused, undercuts, arc craters, spatters, welding tumors, etc., and the surface quality is good; the macroscopic view of the double-beam laser welding joint is On the surface ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com