Welded brush strip without base cloth and its processing technology

A processing technology and brush strip technology, which is applied in the field of non-base fabric welded brush strip and its processing technology, can solve the problems of complex structure and high production cost of the brush strip

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

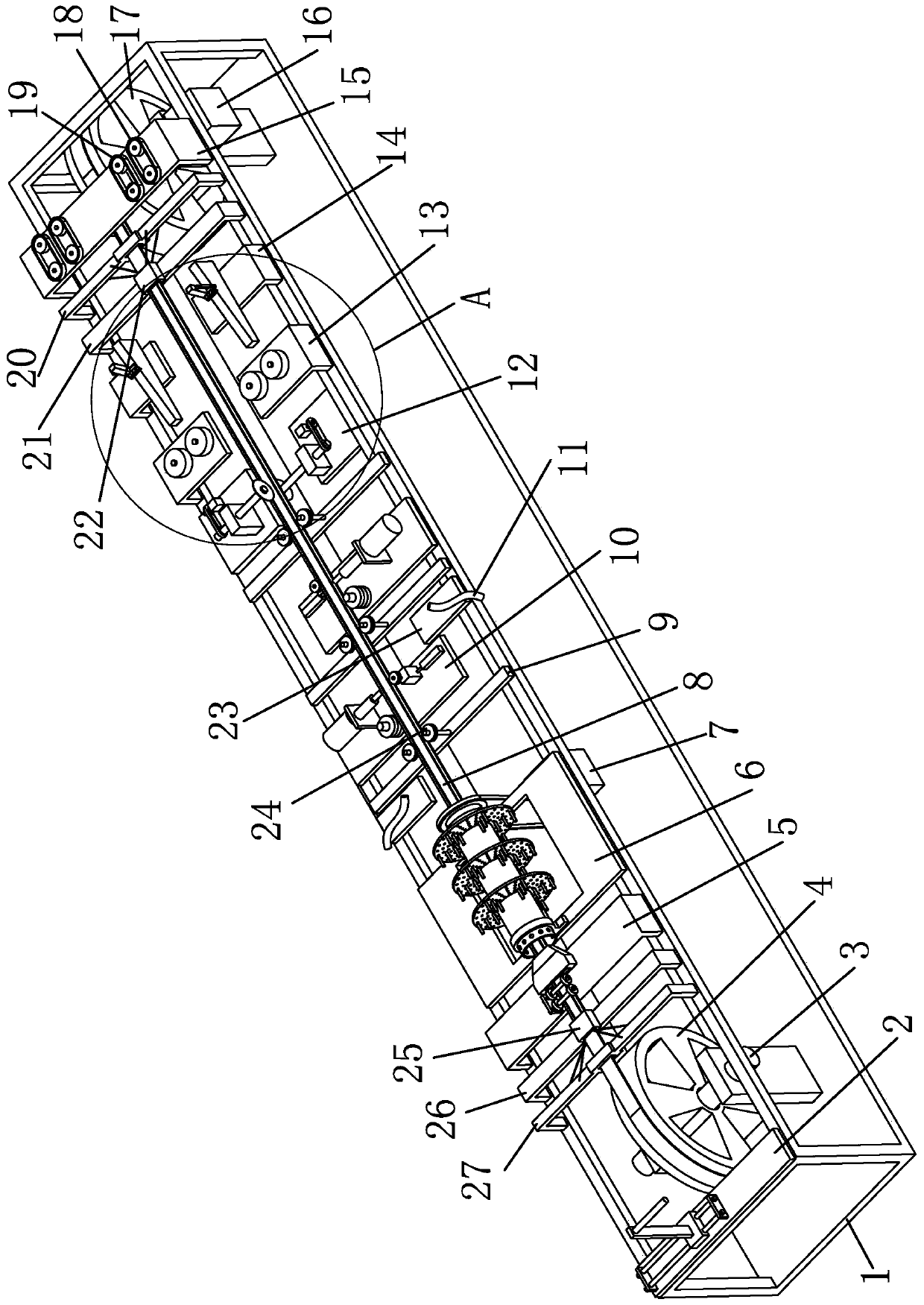

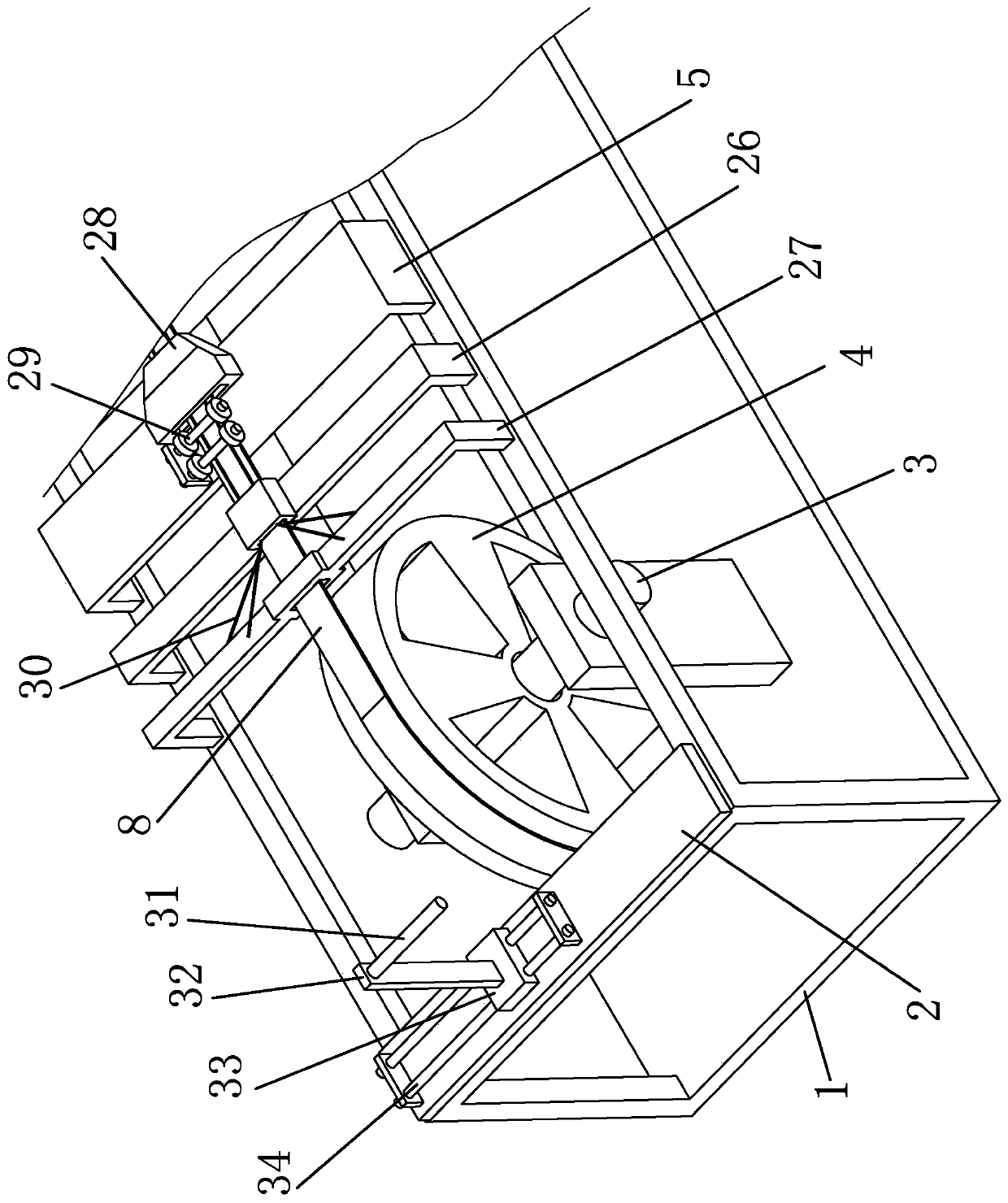

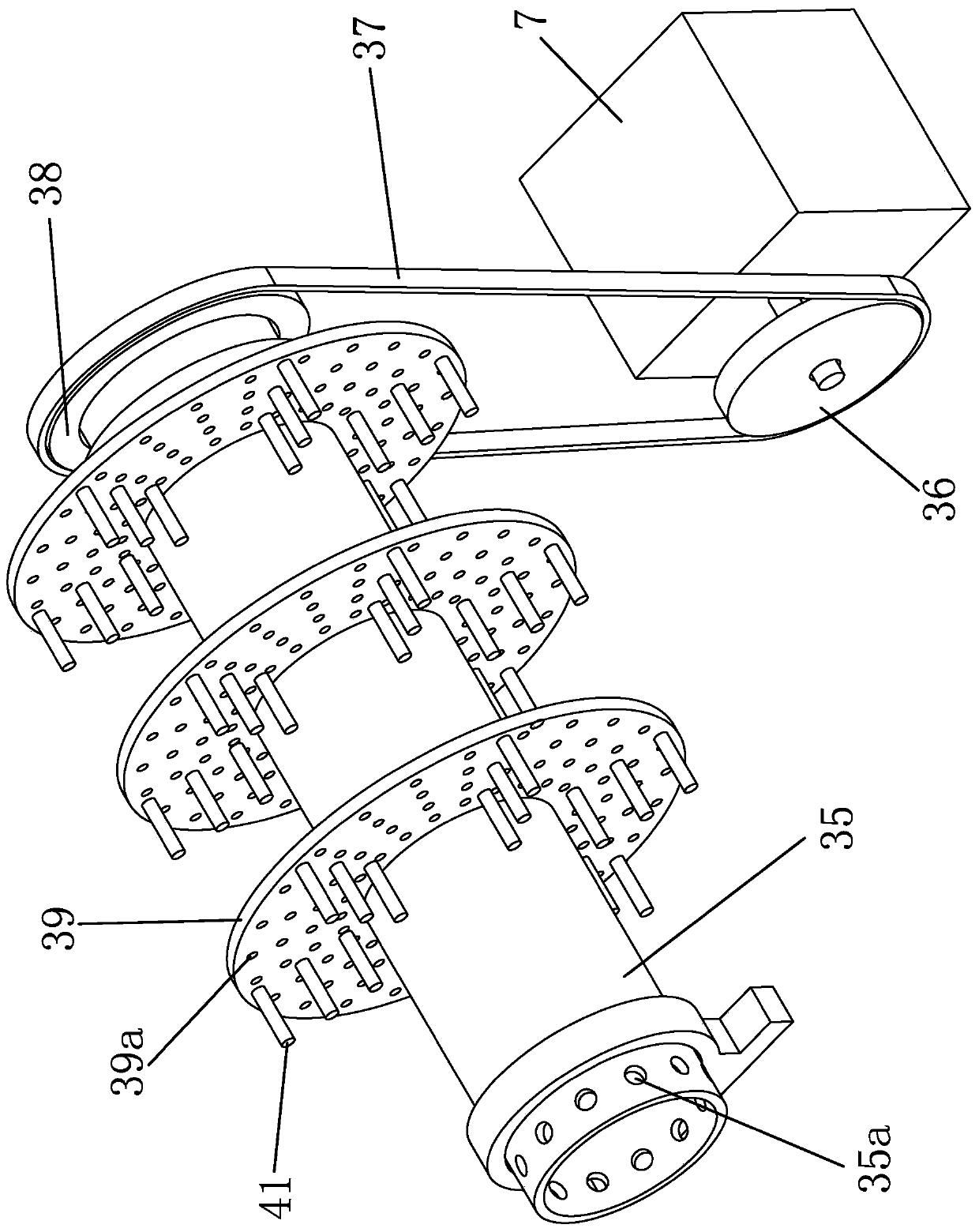

[0109] Embodiment 1 of processing technology: the processing technology of this non-base cloth welded brush bar comprises the following steps: a, material preparation: prepare base plate and yarn, and carry out visual inspection to it; the width of base plate is 4mm; the thickness of base plate 0.78mm; the groove width of the installation groove is 1.7mm; the depth of the installation groove is 0.28mm; the width of the auxiliary part is 0.4mm; the height of the side wings is 0.58mm; The mechanism winds the yarn on the yarn bobbin on the steel belt in the welding seed wool equipment to form a yarn roll for making silk wool; c, conveying bottom plate: through the feeding mechanism in the welding seed wool equipment, the two bottoms The boards are vertically conveyed to both sides of the yarn roll; d. Ultrasonic welding: the two bottom plates are welded on both sides of the yarn roll by the ultrasonic welding mechanism in the welding seed wool equipment to obtain semi-finished pro...

Embodiment 2

[0110] Embodiment two of the processing technology: the processing technology of the welding-type brush bar without base cloth comprises the following steps: a, material preparation: prepare the base plate and the yarn, and carry out appearance inspection to it; the width of the base plate is 4.5mm; The thickness is 0.83mm; the groove width of the installation groove is 1.8mm; the depth of the installation groove is 0.18mm; the width of the auxiliary part is 0.5mm; the height of the side wings is 0.51mm; The thread mechanism winds the yarn on the yarn barrel on the steel belt in the welding seed wool equipment to form a yarn roll for making silk wool; c. Conveying the bottom plate: through the feeding mechanism in the welding seed wool equipment, the two The root base plates are vertically transported to both sides of the yarn roll respectively; d, ultrasonic welding: the two base plates are respectively welded on both sides of the yarn roll by the ultrasonic welding mechanism ...

Embodiment 3

[0111] Embodiment three of processing technology: the processing technology of this non-base cloth welded brush bar comprises the following steps: a, material preparation: prepare base plate and yarn, and carry out visual inspection to it; the width of base plate is 4mm; the thickness of base plate The width of the installation groove is 0.72mm; the groove width of the installation groove is 1.8mm; the depth of the installation groove is 0.37mm; the width of the auxiliary part is 0.4mm; the height of the side wings is 0.55mm; The mechanism winds the yarn on the yarn bobbin on the steel belt in the welding seed wool equipment to form a yarn roll for making silk wool; c, conveying bottom plate: through the feeding mechanism in the welding seed wool equipment, the two bottoms The boards are vertically conveyed to both sides of the yarn roll; d. Ultrasonic welding: the two bottom plates are welded on both sides of the yarn roll by the ultrasonic welding mechanism in the welding see...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com