Robot welding clamp for pollution cleaning device

A robot welding and fixture technology, applied in the direction of auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve the problems of discontinuous and unstable weld seam, inability to guarantee product quality, and difficult control of strength, so as to achieve novel structure and reduce grinding Process, clamping firm and stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

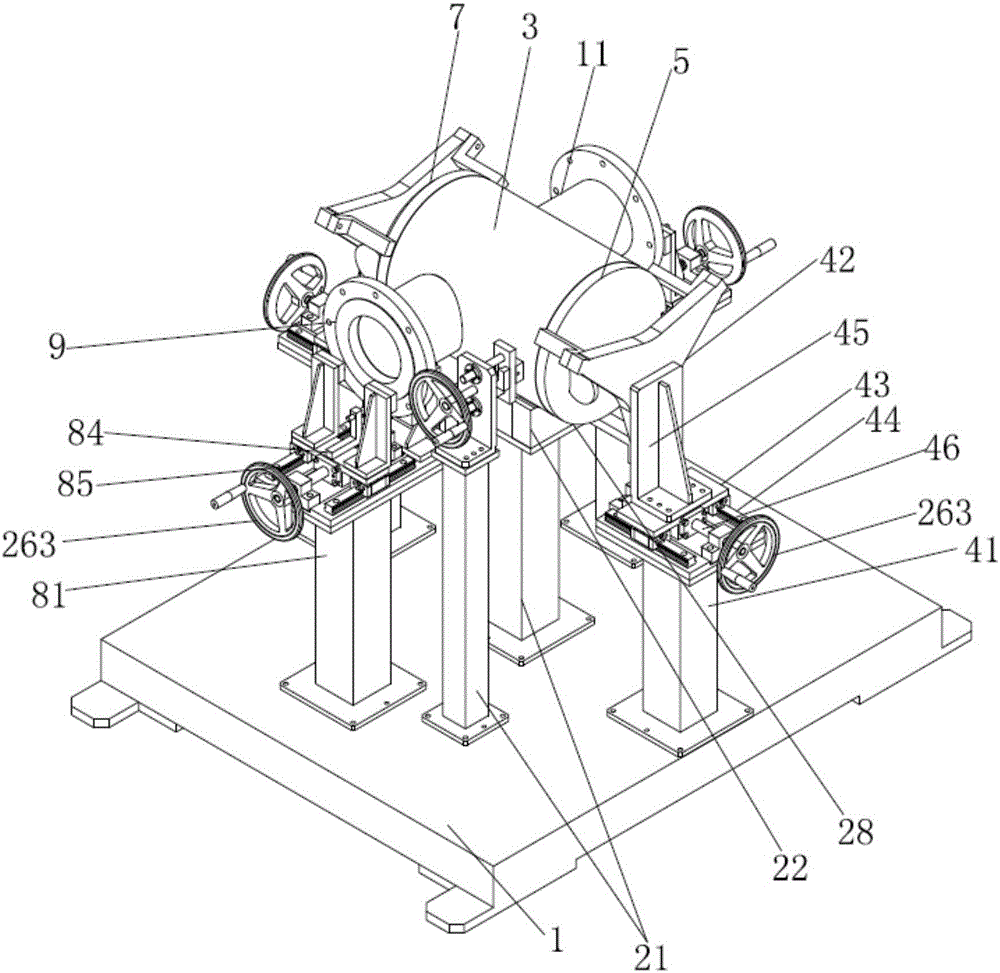

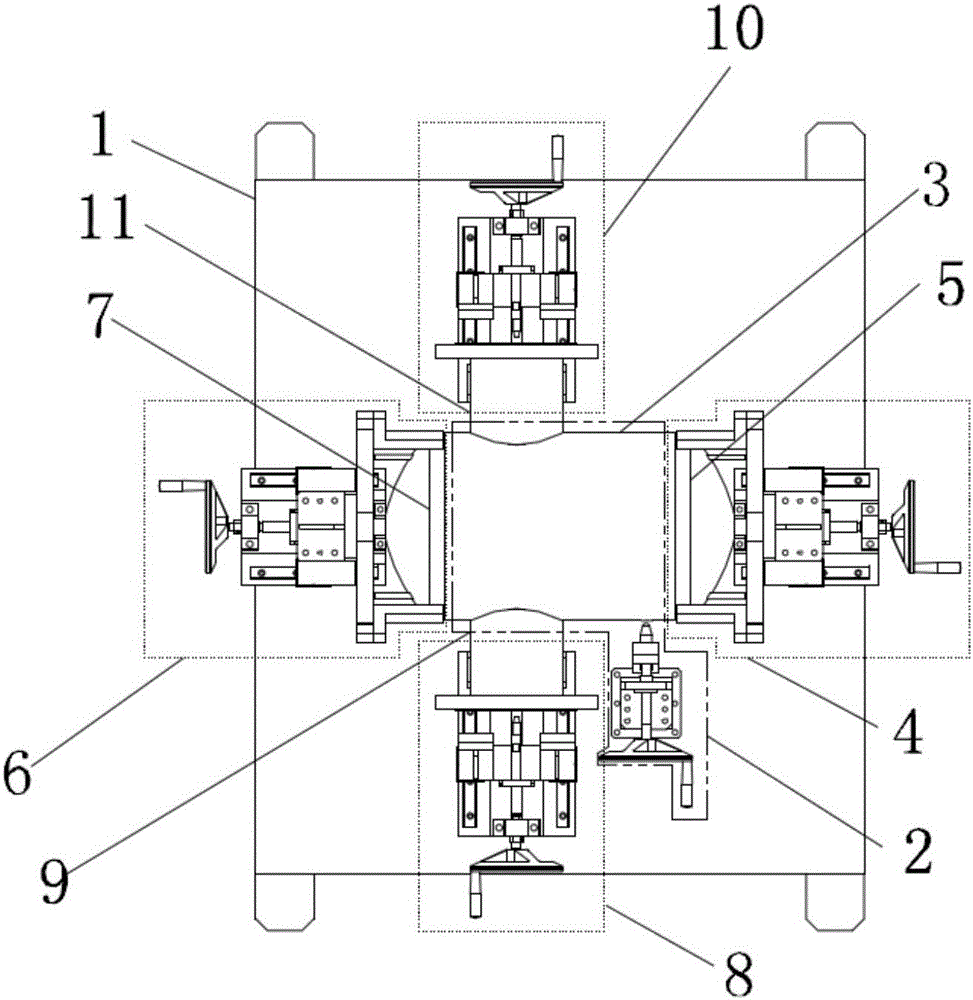

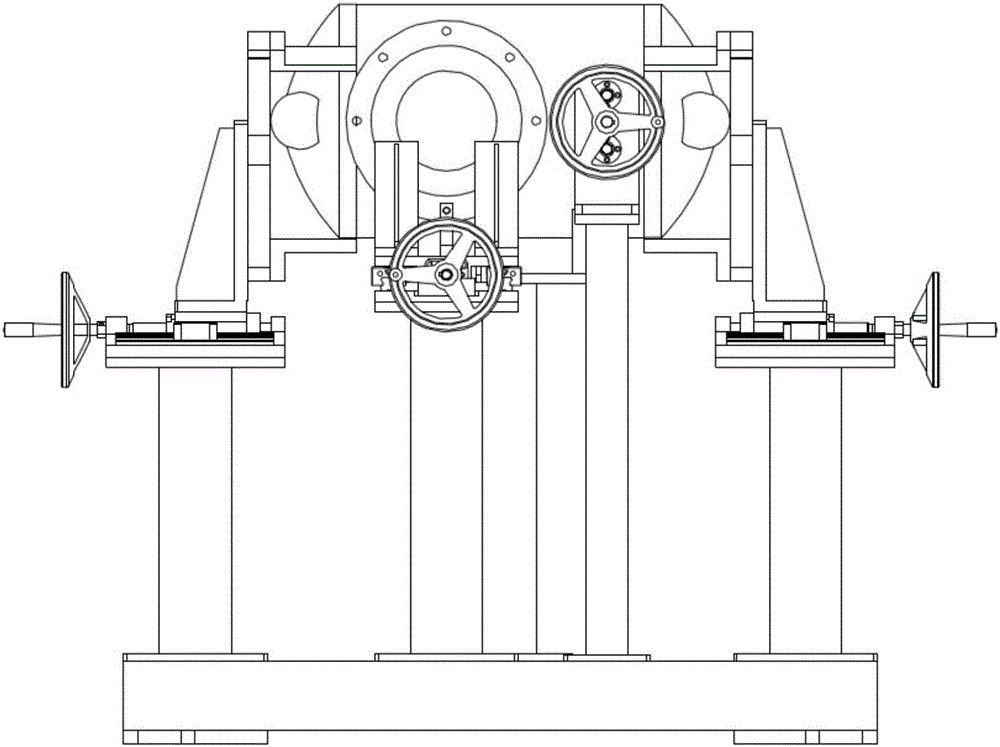

[0034] like Figure 1-4 As shown, this embodiment discloses a robot welding jig for a decontamination device, including a base 1, a first workpiece supporting and clamping mechanism 2, and a second workpiece clamping and centering mechanism both arranged on the base 1 4. The third workpiece clamping and centering mechanism 6 , the fourth workpiece supporting and clamping mechanism 8 and the fifth workpiece supporting and clamping mechanism 10 . The first workpiece support and clamping mechanism 2 is used to support and clamp the first workpiece 3, that is, the central round tank body of the decontamination device; the second workpiece clamping centering mechanism 4, and the third workpiece clamping centering mechanism 6 are respectively used For centering and clamping the second workpiece 5 and the third workpiece 7, that is, the head tank cover and the tail tank cover of the decontamination device; the fourth workpiece supporting and clamping mechanism 8 and the fifth workpie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com