Intelligent wall grinding robot

A robot and intelligent technology, applied in the parts of grinding machine tools, machine tools suitable for grinding workpiece plane, grinding machines, etc., can solve the problems of low work efficiency, poor polishing effect, physical injury of decoration workers, etc., to improve work efficiency , Improve the polishing effect, avoid the effect of bodily harm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings.

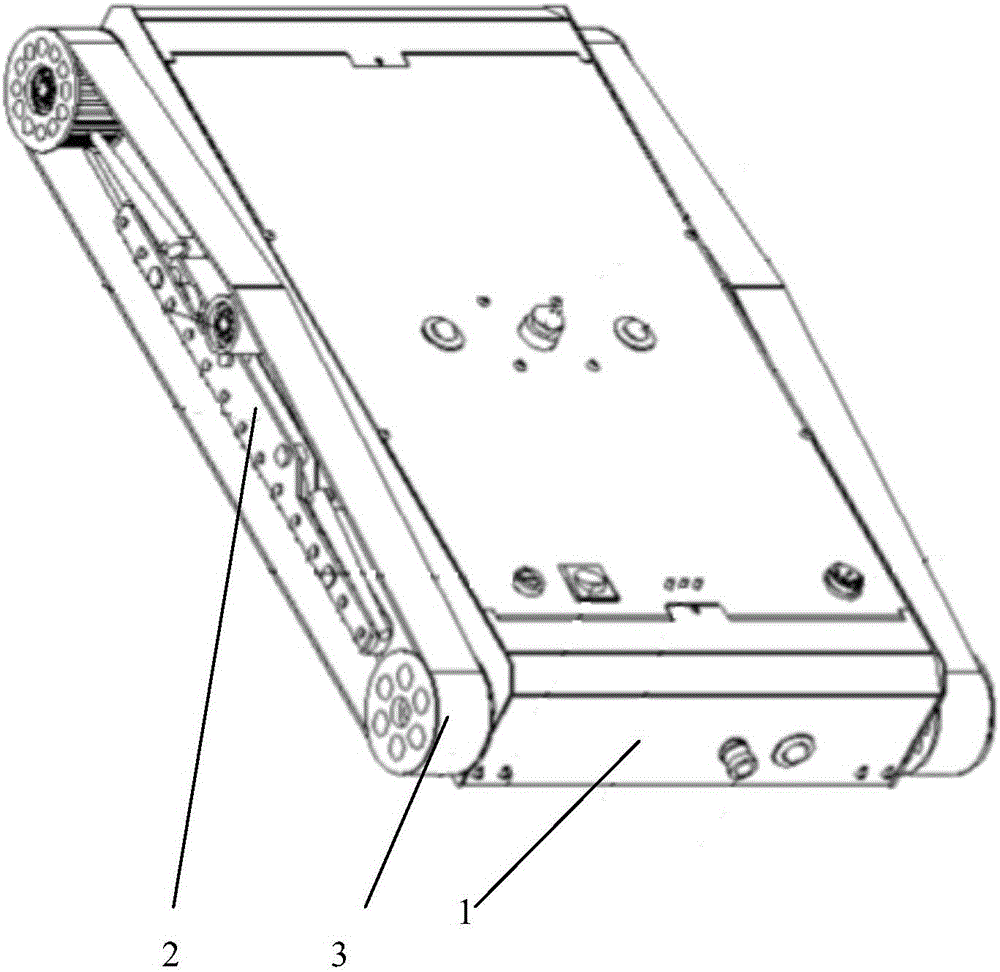

[0033] refer to figure 1 and figure 2 , an intelligent wall grinding robot, including a grinding and polishing head, the grinding and polishing head is provided with a start-stop switch, and the wall grinding robot also includes a casing 1, an adsorption assembly 2 for adsorbing the robot on the wall And a walking assembly 3 for realizing that the robot walks along the wall, the adsorption assembly is installed on the bottom of the casing, the walking assembly 3 is installed on the bottom side of the casing 2, and the grinding and polishing head is installed on the bottom of the casing 1;

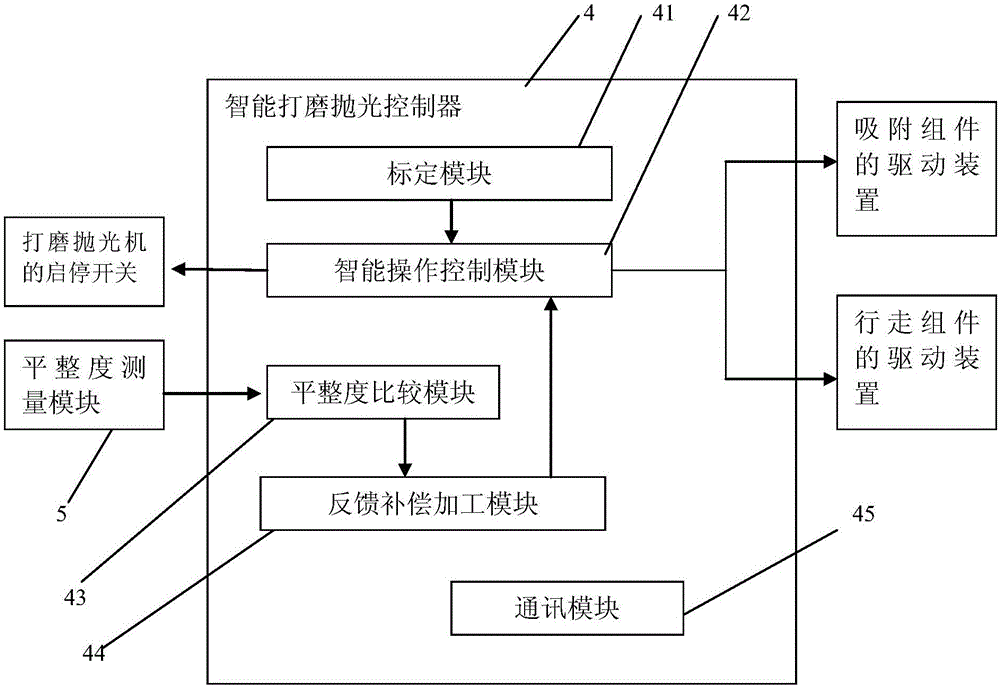

[0034] An intelligent grinding and polishing controller 4 is installed in the casing 1, and the intelligent grinding and polishing controller 4 includes:

[0035] A calibration module 41 for setting a reference coordinate system and controlling the trajectory according to the calib...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com