A kind of anti-adhesive high stability glue making machine

A high-stability, glue-making machine technology, applied in the field of glue-making equipment, can solve the problems of difficult cleaning, rapid falling off, shaking, etc., and achieve the effect of ensuring processing quality, large market competitiveness, and convenient scraping and cleaning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

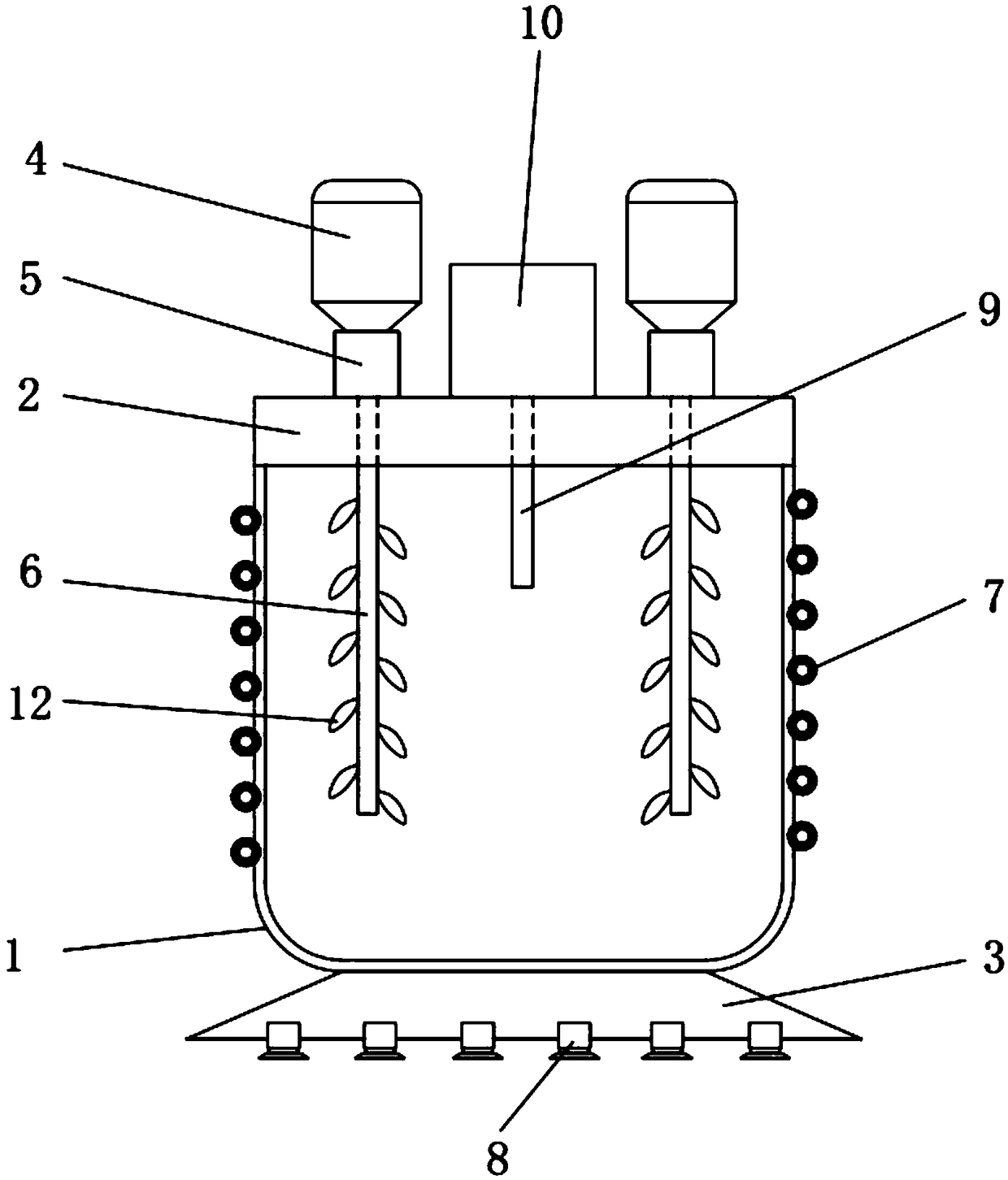

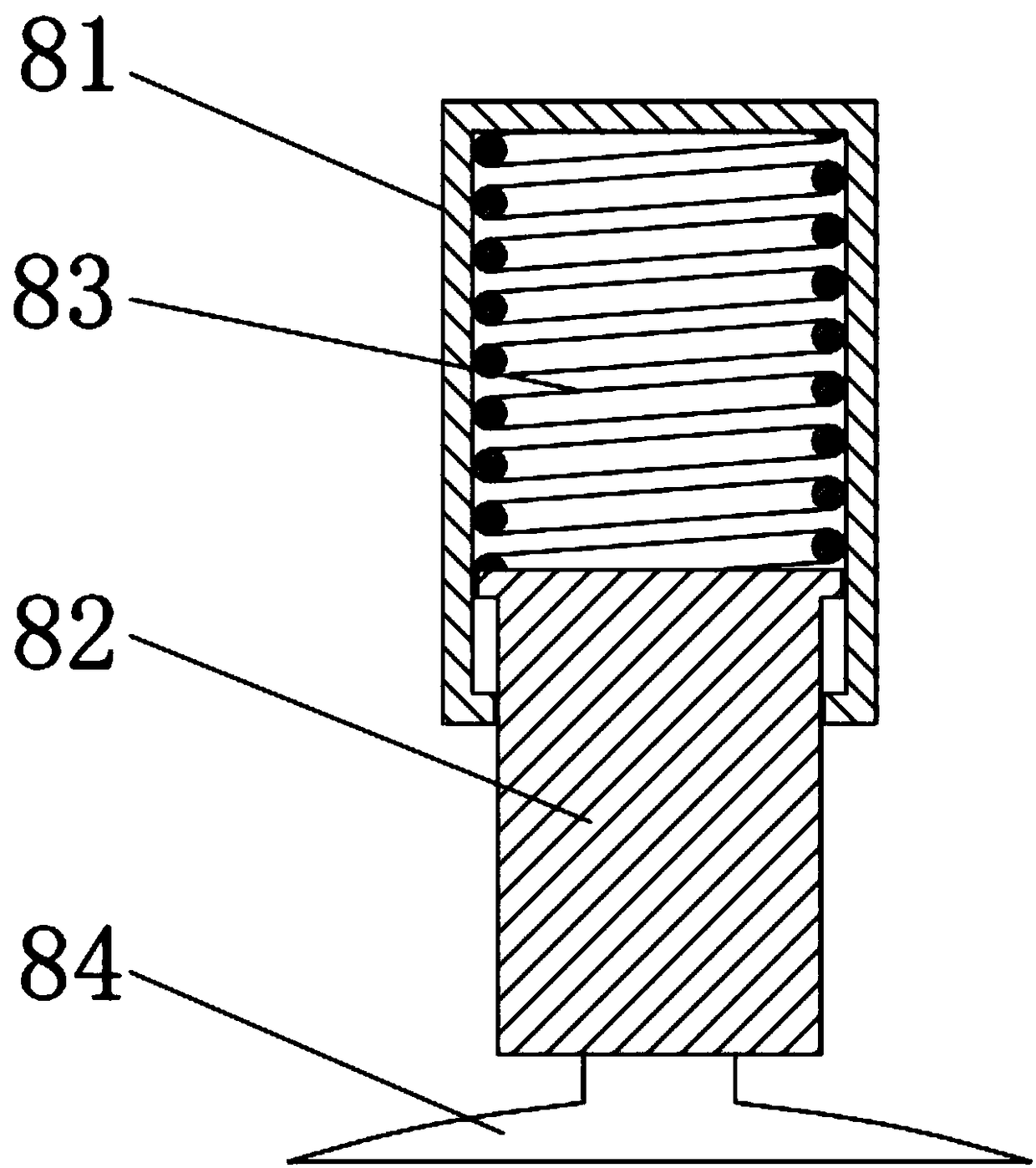

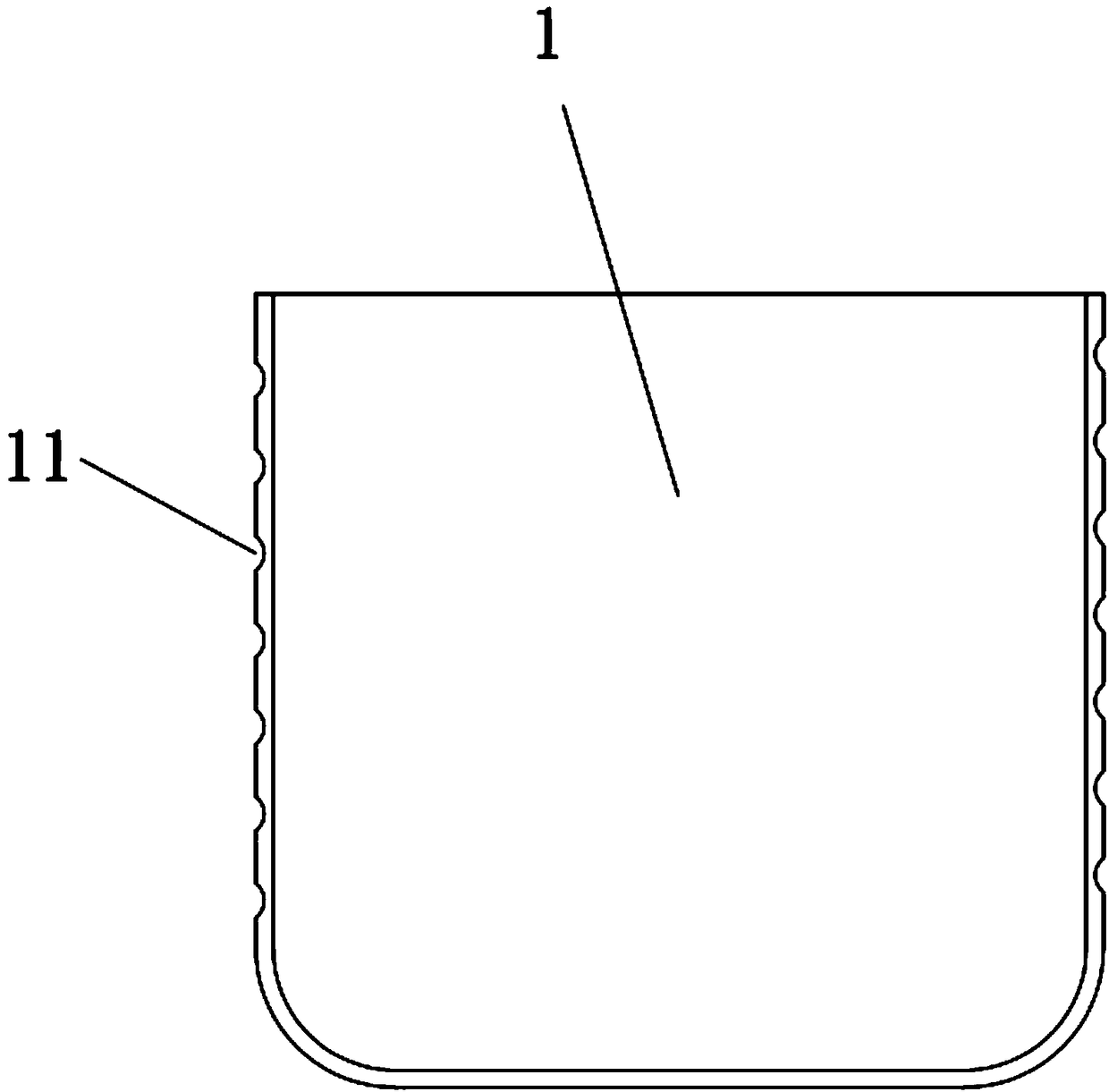

[0034] The anti-adhesive glue making machine with high stability according to the present invention, such as figure 1 As shown, it includes: a mixing cylinder body 1 and an upper cover plate 2 and a base 3 located at the upper and lower ends of the mixing cylinder body 1; the upper cover plate 2 is provided with two sets of symmetrically distributed stirring mechanisms; the stirring mechanism includes: The motor 4, the reducer 5 and the stirring shaft 6; wherein the stirring motor 4 is a three-phase asynchronous motor, the main shaft of the stirring motor 4 is connected to the input shaft of the reducer 5; the stirring shaft 6 passes through the upper cover 2 and reduces The output shaft of the device 5 is connected; the stirring shaft 6 is arranged inside the stirring cylinder 1; figure 1 , figure 2 As shown, the side of the mixing cylinder body 1 is provided with an external heating pipe 7, which is spirally wound around the periphery of the mixing cylinder body 1, and is fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com