A two-component cotton

A two-component, aluminum plate technology, applied in layered products, synthetic resin layered products, metal layered products, etc. Product service life and other issues, to achieve good radiation protection performance, excellent sound absorption, and increase the effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with specific embodiments.

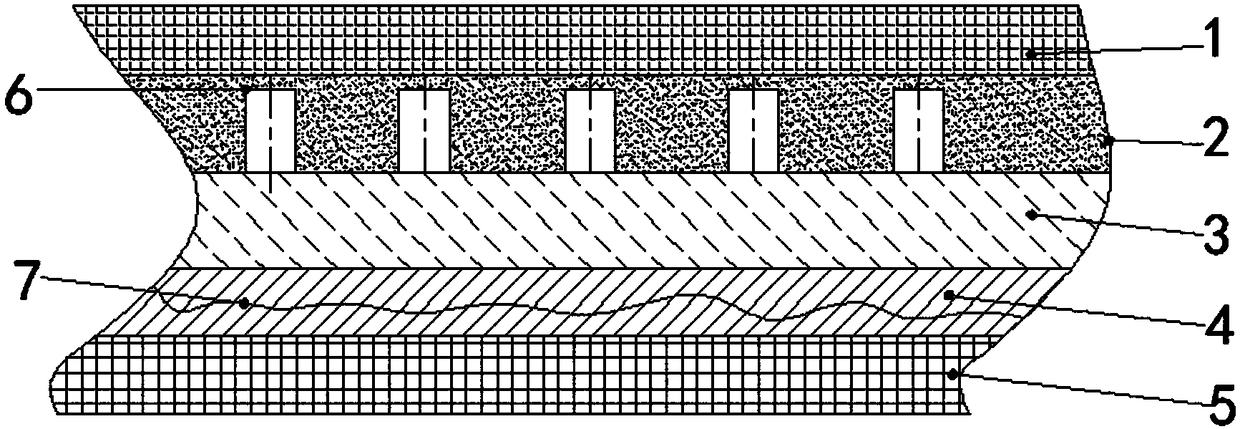

[0026] A two-component cotton, comprising a silicone rubber layer 1, an aluminum plate 2, a two-component cotton 3, a radiation protection layer 4 and an XPE layer 5;

[0027] The thickness of the XPE layer 5 is 3-5mm, and its shape matches the surface of the vehicle body, and plays the roles of heat insulation, cushioning, sound absorption, molding, oil resistance and acid resistance, and is non-toxic, tasteless, energy-saving and environmentally friendly;

[0028] The radiation-proof layer 4 has a thickness of 3 to 5 mm and is located on the outer surface of the XPE layer. The base material of the radiation-proof layer is high-tough radiation-proof rubber, and the base material is embedded with a radiation-proof metal braided mesh 7 to prevent radiation. The material of the metal braided mesh 7 may be one or more of stainless steel, magnesium aluminum alloy, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com