Engine front bracket

A front bracket and engine technology, applied in power plant, jet propulsion device, internal combustion propulsion device, etc., to prevent structural deformation and screw loosening, improve seismic performance and safety performance, and reduce welding flashes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

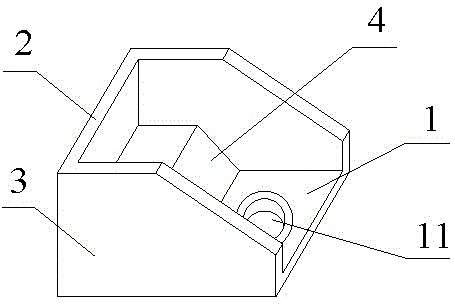

[0017] see figure 1 As shown, the embodiment of the present invention provides a front bracket of the engine, the length of the front bracket of the engine is 245mm, and the width is 135mm. The engine front bracket includes an integrally formed bottom wall 1, a front wall 2 and two side walls 3, and is characterized in that: The wall 2 is fixedly installed on the front end of the bottom wall 1, and is fixedly connected with the two side walls 3 respectively; the rear end of the bottom wall 1 is provided with a process hole 11, specifically, the diameter of the process hole 11 is 50 mm. The welding bump on the front bracket of the engine is reduced, which achieves the purpose of aesthetics and meets the needs of customers.

[0018] The front end portion of the bottom wall 1 is fixedly equipped with reinforcing ribs 4 , and the reinforcing ribs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com