A vacuum timely leak detection high-speed rail tank car with a damping and shock-absorbing platform

A technology for high-speed rail and tank cars, which is applied to railway car body parts, springs/shock absorbers, liquid tightness measurement using liquid/vacuum degree, etc. It can solve the problem of undurable, troublesome and poor shock absorption effects of shock absorption facilities, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Now in conjunction with accompanying drawing, the present invention is described in further detail.

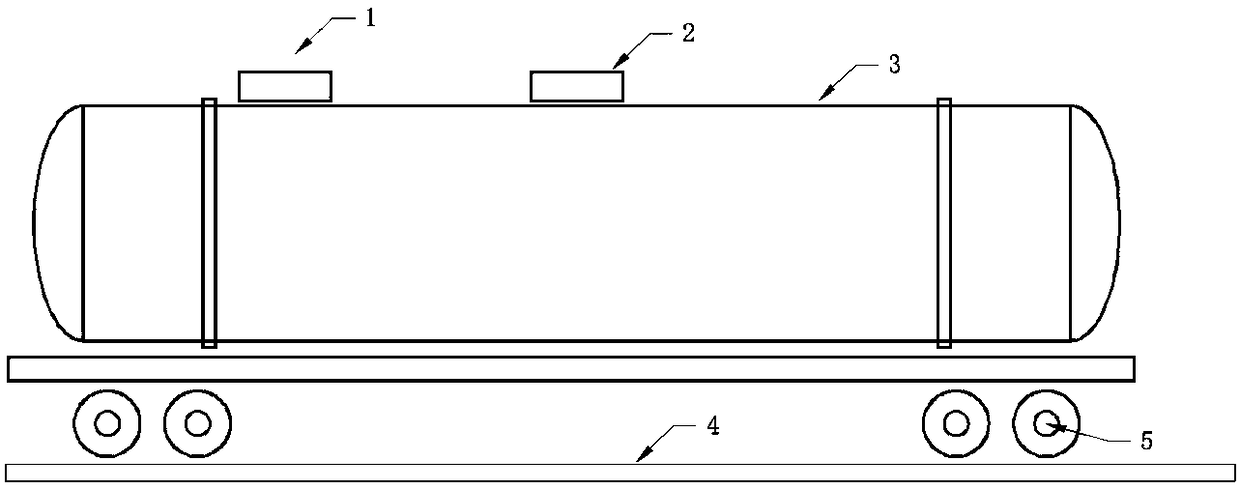

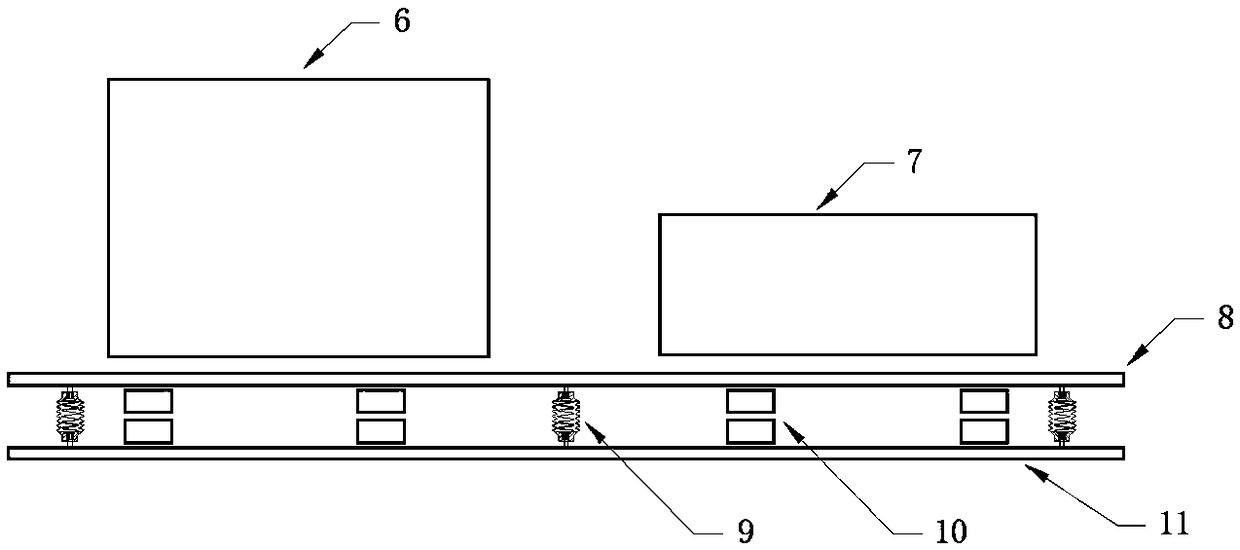

[0020] Such as Figure 1-Figure 3 The high-speed rail tank car with vacuum and timely leak detection with a damping shock-absorbing platform is shown. The high-speed rail tank car rolls on the rail 4 through the wheels 5. The tank body 3 of the high-speed rail tank car is provided with a chassis 1. The chassis 1 is connected to the tank car through the shock-absorbing platform. The chassis There is a vacuum pump 6 and a control box 7 inside. The vacuum pump 6 pumps air to the tank body 3 of the high-speed rail tanker. The control box 7 controls the work of the vacuum pump 6, and sends the pumping and vacuum data to the control station through electronic signals for parameter monitoring. According to the vacuum Judging whether there is a leak in the tank based on the pumping data.

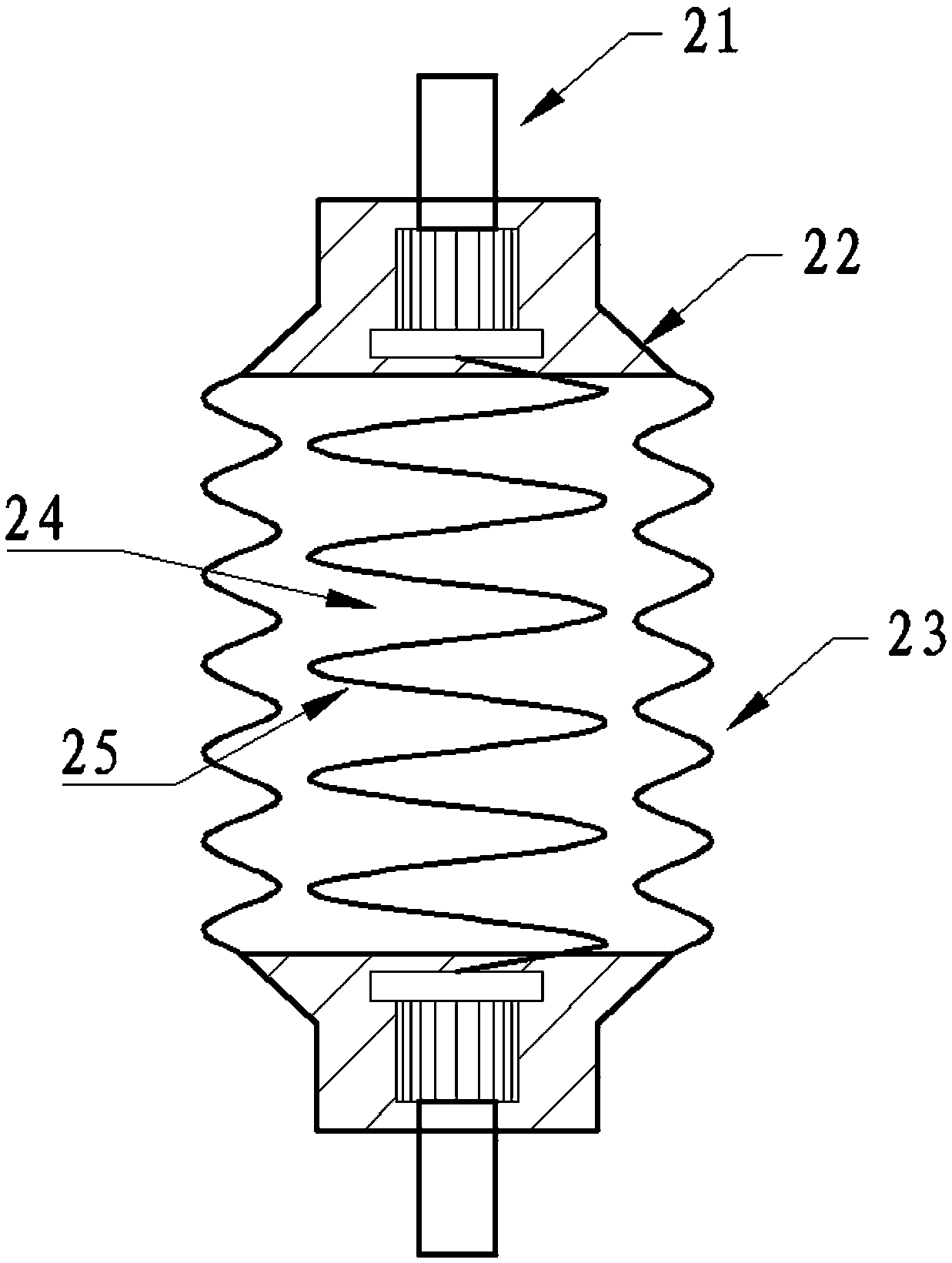

[0021] A plurality of strong magnets 10 are arranged between the table top 8 of the shoc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com