Automatic packaging, boxing and stacking packaging line for halide products

A technology for automatic packaging and stewed products, which is applied in the field of food packaging, can solve the problems of low efficiency and high cost, and achieve the effects of high degree of automation, high production efficiency and good reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be described in further detail below in conjunction with the accompanying drawings.

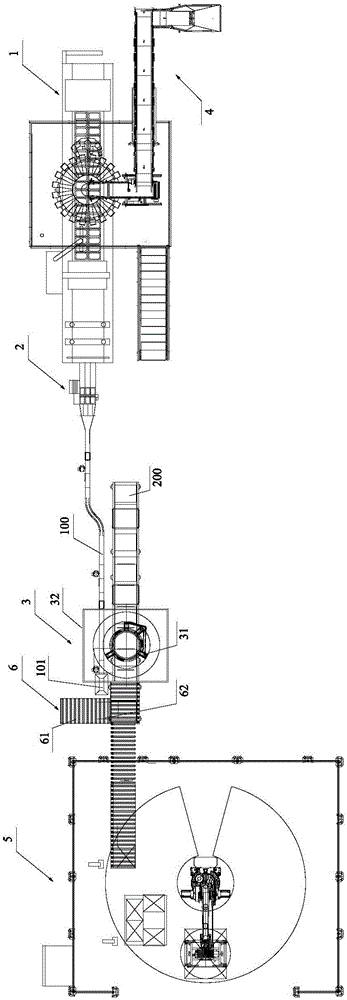

[0048] see figure 1 As shown, the present invention provides an automatic packaging and palletizing packaging line for halogen products, which includes a modified atmosphere packaging machine 1 , a doubling machine 2 , a packing robot 3 and a weighing device 4 .

[0049] Modified atmosphere packaging machine 1 uses stretch film to make the exposed products into modified atmosphere packaging, so that the stewed products can be stored for a longer period of time, and the flavor and taste of the stewed products can be guaranteed.

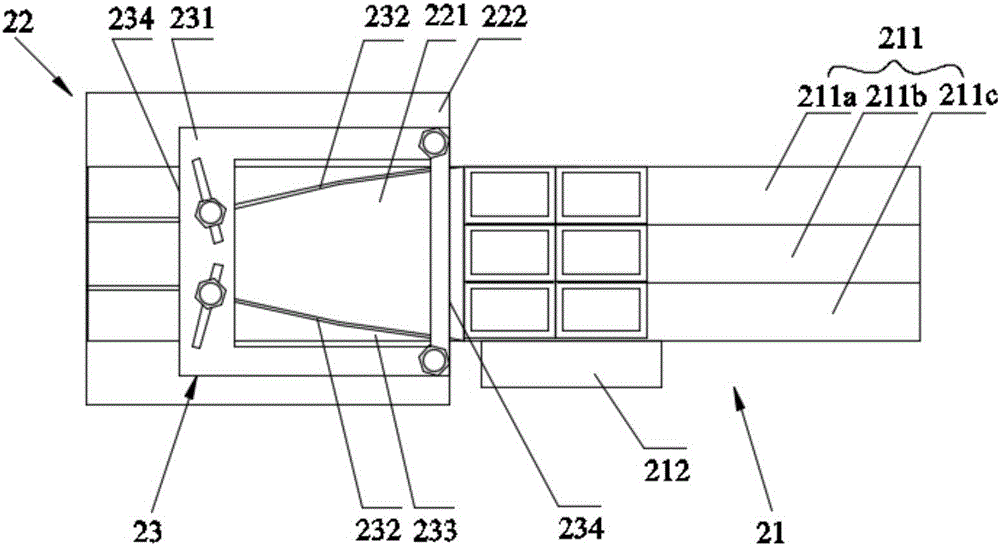

[0050] Doubling machine 2 is connected with modified atmosphere packaging machine 1, see figure 2 As shown, the doubling machine 2 in the present invention includes an input device 21 , an output device 22 and a guide assembly 23 .

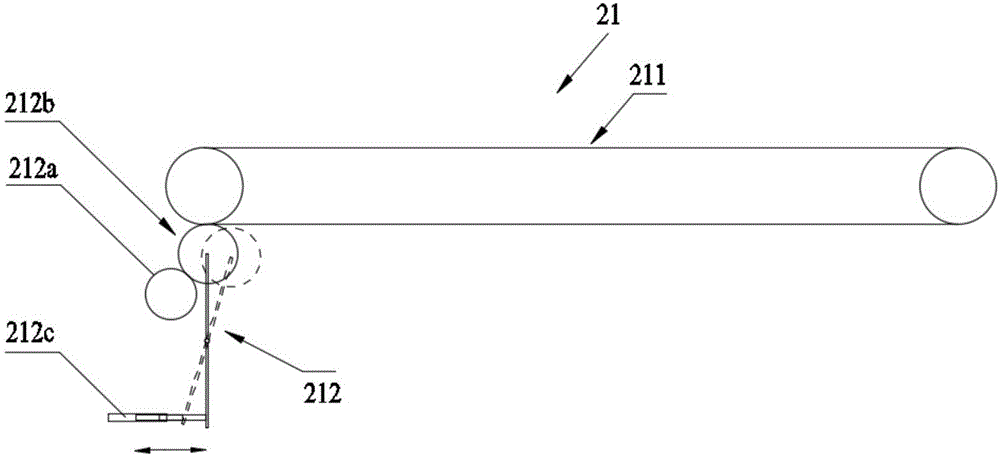

[0051] The input device 21 includes a conveyor belt set 211, the conveyor belt set 211 includes at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com