A kind of synthetic technique of increasing production amine

A synthesis process and a technology for increasing the production of amines, which are applied in the field of preparation technology for increasing the production of amines, can solve the problems of long preparation time, short synthesis time, and low cost of the production-increasing amines, and achieve shortening of reaction time, improvement of solvent recovery rate, and elimination of reaction inhibition Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] A kind of synthetic technique of increasing production amine, comprises the following steps:

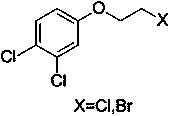

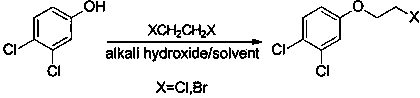

[0046]A. After dissolving 3,4-dichlorophenol and alkali metal hydroxide in a polar aprotic solvent, add 1,2-dihaloethane, heat up, keep warm and reflux for 0.5h, rectify, and recover untreated The reacted 1,2-dihaloethane and some polar aprotic solvents, the bottom of the still is a mixture of intermediate products and polar aprotic solvents;

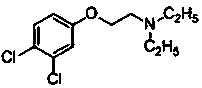

[0047] B. Add diethylamine to the mixed solution of the intermediate product obtained in step A and the polar aprotic solvent, heat to reflux for 8 hours, then add alkali metal hydroxide, stir, then filter, and obtain after rectification of the filtrate Increase production of amine;

[0048] In the above step A and step B, the alkali metal hydroxide is potassium hydroxide.

Embodiment 2

[0050] A synthesis technique for increasing production of amines, comprising the following steps:

[0051] A. After dissolving 3,4-dichlorophenol and alkali metal hydroxide in a polar aprotic solvent, add 1,2-dihaloethane, heat up, keep warm and reflux for 1 hour, rectify, and recover unreacted 1,2-dihaloethane and some polar aprotic solvents, the bottom of the still is a mixed solution of intermediate products and polar aprotic solvents;

[0052] B. Add diethylamine to the mixture of the intermediate product obtained in step A and the polar aprotic solvent, heat to reflux for 10 hours, then add alkali metal hydroxide, stir, then filter, and obtain Increase production of amine;

[0053] In the above step A and step B, the alkali metal hydroxide is sodium hydroxide.

[0054] The polar aprotic solvent in this example is DMF; in step A, the 1,2-dihaloethane is 1,2-dichloroethane.

Embodiment 3

[0056] A synthesis technique for increasing production of amines, comprising the following steps:

[0057] A. After dissolving 3,4-dichlorophenol and alkali metal hydroxide in a polar aprotic solvent, add 1,2-dihaloethane, heat up, keep warm and reflux for 0.5h, rectify, and recover untreated The reacted 1,2-dihaloethane and some polar aprotic solvents, the bottom of the still is a mixture of intermediate products and polar aprotic solvents;

[0058] B. Add diethylamine to the mixture of the intermediate product obtained in step A and the polar aprotic solvent, heat to reflux for 9 hours, then add alkali metal hydroxide, stir, then filter, and obtain after rectification of the filtrate Increase production of amine;

[0059] In the above step A and step B, the alkali metal hydroxide is sodium hydroxide.

[0060] The polar aprotic solvent in this example is DMAC; in step A, the 1,2-dihaloethane is 1,2-dibromoethane; the amount of alkali metal hydroxide is 3,4-di The amount of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com