A kind of lignin/tannin composite polyurethane coating and preparation method thereof

A technology of compounding polyurethane and lignin, which is applied in the direction of coating, paper coating, non-fiber pulp addition, etc., can solve the problems of moisture resistance, antibacterial, poor weather resistance, refractory degradation, environmental pollution, etc., and promote the improvement of hydrophobic performance. Crosslink density, effect on coating properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

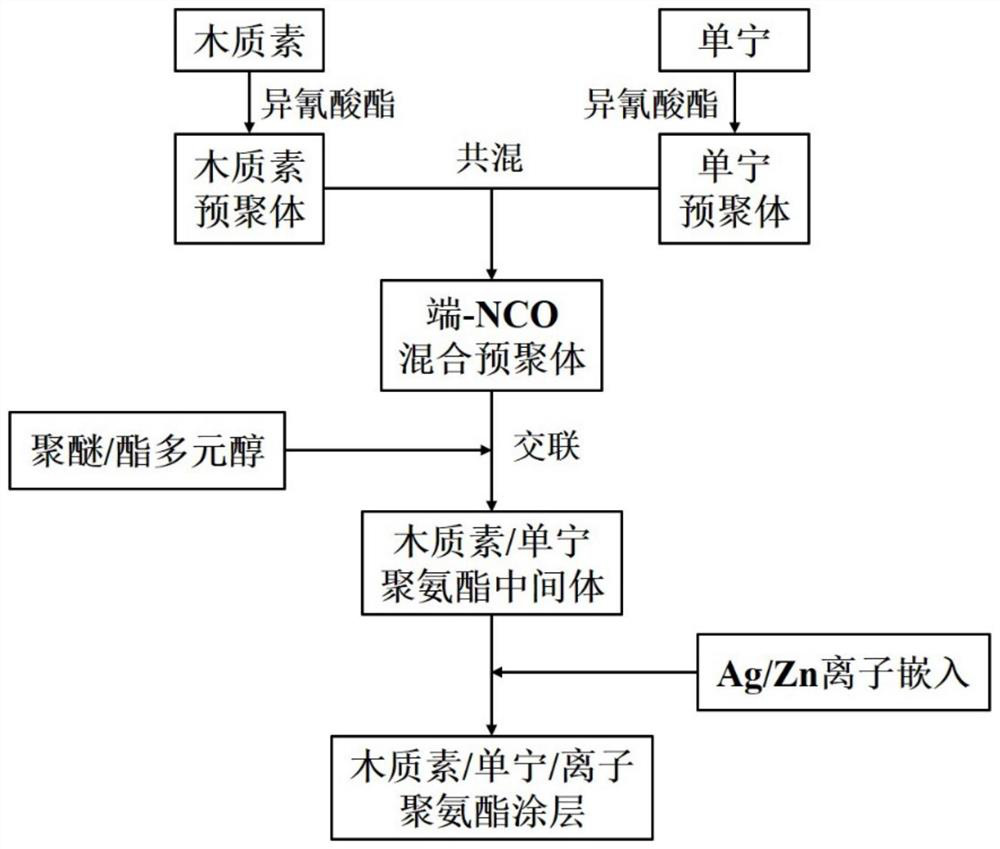

[0033] A lignin / tannin composite polyurethane coating and a preparation method thereof, comprising the following steps (refer to figure 1 shown):

[0034] Step 1: Under the protection of nitrogen, according to the molar ratio of the total hydroxyl groups of lignin and hexamethylene diisocyanate as 1:3, take 10 g of acetic acid lignin and hexamethylene diisocyanate of the corresponding quality, and dissolve them in dimethyl methylene diisocyanate. In the sulfone, a dibutyltin dilaurate catalyst with a mass of 0.02% lignin was added to make the total concentration (mass fraction) of lignin and hexamethylene diisocyanate in dimethyl sulfoxide to be 30%, and the temperature was kept at 30 °C for 0.5 h, System 1 is obtained.

[0035]Step 2: Under the protection of nitrogen, according to the molar ratio of the total hydroxyl groups of tannins and hexamethylene diisocyanate is 1:0.8, take 10g of tannins and hexamethylene diisocyanate of the corresponding quality, and dissolve them i...

Embodiment 2

[0041] A lignin / tannin composite polyurethane coating and a preparation method thereof, comprising the following steps (refer to figure 1 shown):

[0042] Step 1: under nitrogen protection, be 1: 1 according to the mol ratio of total hydroxyl groups of lignin and toluene diisocyanate, get 10g acetic acid lignin, the toluene diisocyanate of corresponding quality, be dissolved in dimethyl sulfoxide, add lignin The total concentration (mass fraction) of lignin and toluene diisocyanate in dimethyl sulfoxide was 10% with 0.08% mass dibutyltin dilaurate catalyst, and the system was kept at 70°C for 2h to obtain system 1.

[0043] Step 2: under nitrogen protection, according to the mol ratio of tannin total hydroxyl group and toluene diisocyanate is 1: 2.5, get 10g tannin, toluene diisocyanate of corresponding quality, dissolve in dimethyl sulfoxide, add tannin quality 0.02% dibutyltin dilaurate catalyst was used to make the total concentration (mass fraction) of tannin and toluene ...

Embodiment 3

[0049] A lignin / tannin composite polyurethane coating and a preparation method thereof, comprising the following steps (refer to figure 1 shown):

[0050] Step 1: under nitrogen protection, be 1: 2 according to the mol ratio of lignin total hydroxyl and diphenylmethane diisocyanate, get 10g acetic acid lignin, the diphenylmethane diisocyanate of corresponding quality, be dissolved in dimethyl methylene In the sulfone, a dibutyltin dilaurate catalyst with 0.05% lignin mass was added, so that the total concentration (mass fraction) of lignin and diphenylmethane diisocyanate in dimethyl sulfoxide was 30%, and the temperature was kept at 50 °C for 1.5 h, System 1 is obtained.

[0051] Step 2: Under nitrogen protection, according to the molar ratio of total tannin hydroxyl groups and diphenylmethane diisocyanate as 1:1.5, take 10g of tannin and diphenylmethane diisocyanate of the corresponding mass, and dissolve them in dimethyl sulfoxide. Add 0.02% tannin mass dibutyltin dilaura...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com