A kind of production method and production device of modified PVC

A production device and modification technology, applied in the direction of inert gas generation, etc., can solve the problems of low utilization rate of equipment, long production cycle of a single kettle, long feeding time, etc., so as to save the heating time, shorten the feeding time, The effect of stabilizing the reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A kind of production method of modified PVC provided by the present embodiment comprises the following steps:

[0029] 108 polymerization reactor is used, and the kettle is coated before feeding, and the coating liquid is evenly sprayed on the inside of the polymerization reactor, the top of the condenser, and the transition piece to prevent the kettle from sticking, and then add a buffer to the polymerization reactor , then adjust the pH value of the system to 6.7-7.8, and then prepare for feeding;

[0030] Add vinyl chloride monomer to the polymerization reactor, and add cold water and hot water to the polymerization reactor at the same time, so that the temperature of the mixed system formed in the polymerization reactor is kept at about 57°C, the temperature of the cold water is about 25°C, and the temperature of the hot water is about 25°C. The temperature of the water is about 95°C; then add dispersant B, dispersant A and initiator into the polymerization reactor,...

Embodiment 2

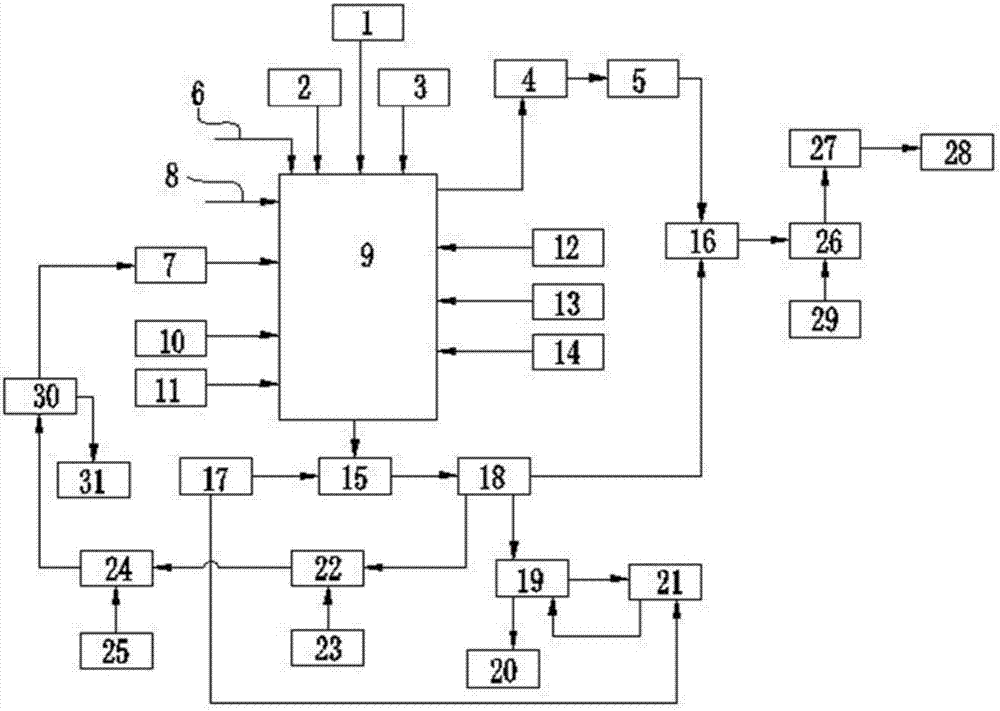

[0037] See figure 1 As shown, the production device of modified PVC provided by the present invention comprises a polymerization reactor 9, and the polymerization reactor 9 is connected with a cold water injection pipe 8 and a hot water injection pipe 6, and the polymerization reactor 9 is also respectively connected with a kettle liquid storage tank 14. Buffer storage tank 11, fresh vinyl chloride monomer storage tank 12, dispersant A storage tank 2, dispersant B storage tank 1, initiator storage tank 3, terminator storage tank 10, recovery vinyl chloride monomer storage tank 7. The emergency terminator storage tank 13 and the discharge tank 15; the polymerization reactor 9 is a jacketed reactor, and the jacket layer of the polymerization reactor is provided with a cooling water inlet and a cooling water outlet; the top condenser of the polymerization reactor 4. A cooling water inlet and a cooling water outlet are provided; during the polymerization reaction of the polymeriza...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com