A low rolling resistance tire tread rubber composition and tire manufactured therefrom

A technology of low rolling resistance and rubber composition, which is applied in the field of low rolling resistance tire tread rubber composition and the tire manufactured thereof, can solve the problems of reducing tire rolling resistance, etc., and achieves enhanced phase distribution, enhanced interaction, and improved dispersion. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

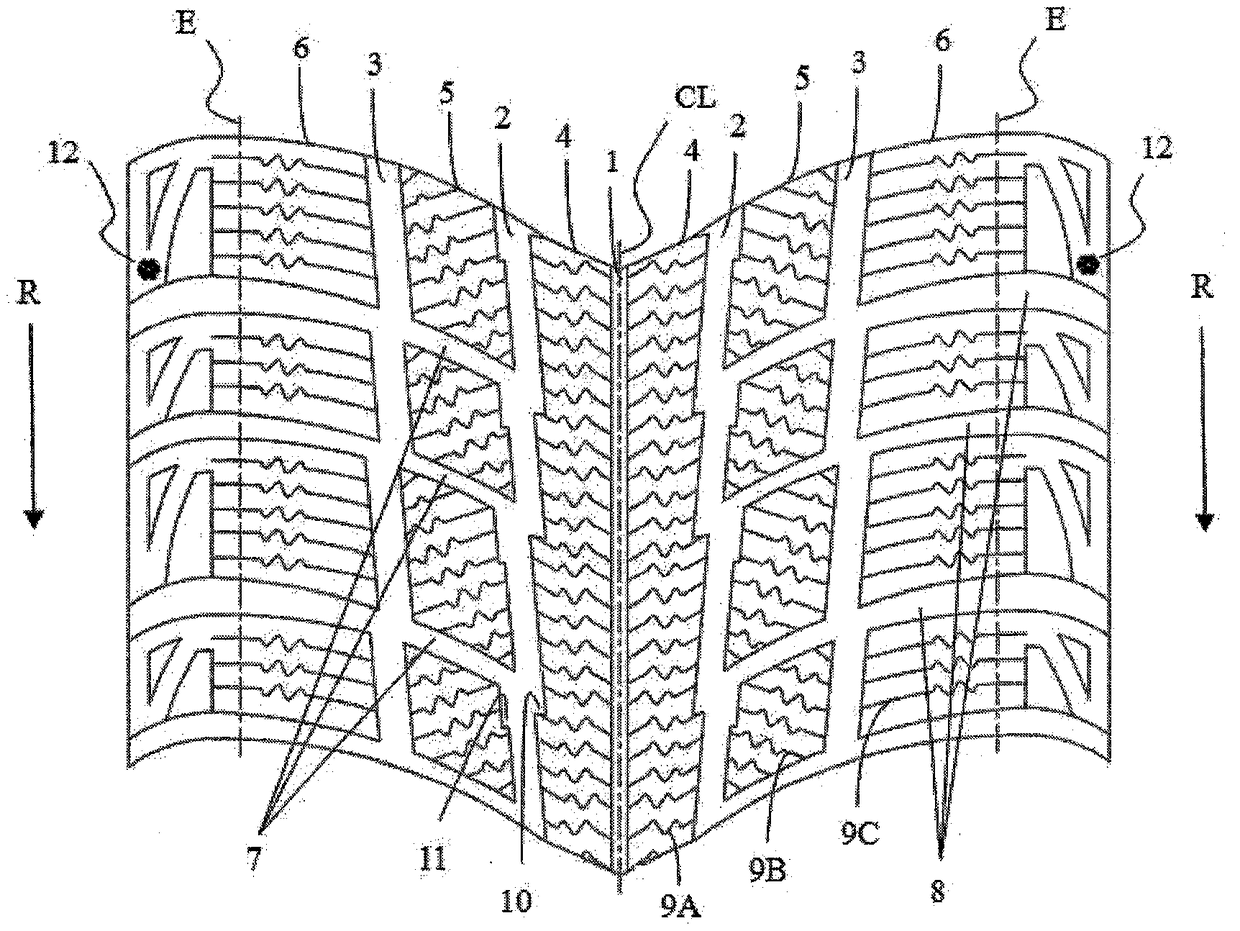

Image

Examples

Embodiment

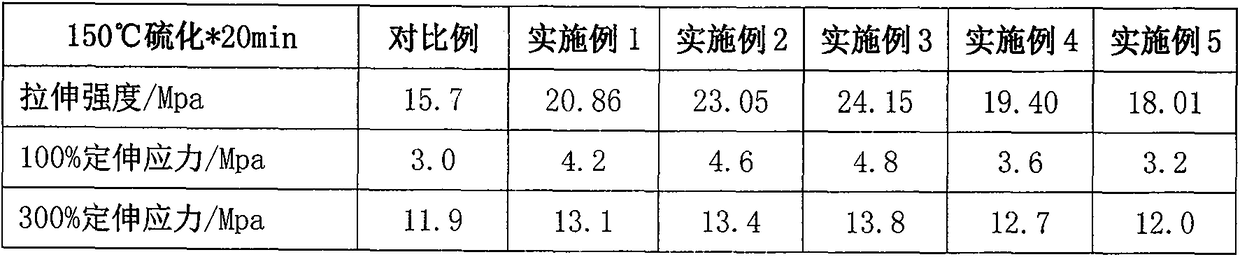

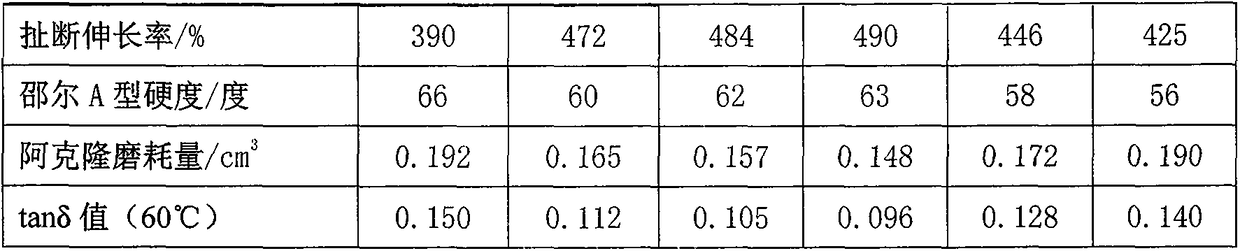

[0098] Embodiment 1, 2, 3, 4, 5 described a kind of low rolling resistance tire tread rubber composition formulation components and parts by weight are as Table 1: (the content unit of each raw material in Table 1 is: parts by weight)

[0099] Table 1 Raw material and weight of tire tread rubber composition

[0100] Recipe Components

Example 1

Example 2

Example 3

Example 4

Example 5

Natural rubber STR20

50

55

60

65

70

Solution polystyrene butadiene rubber SSBR4525

20

25

20

30

0

Neodymium Butadiene Rubber BunaNd22EZ

20

15

20

0

20

guayule gum

10

5

0

5

10

Carbon black ECORAX1670

25

20

20

30

35

Silica ULTRASIL 5000GR

30

35

35

25

20

2.5

3

3

2

1.5

0.3

0.4

0.4

0.2

0.2

Silica dispersant PEG4000

1

1.5

1.5

0.5

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com