A kind of modified rubber oil additive, preparation method and modified rubber oil thereof

A technology for modifying rubber and rubber oil, applied in the field of rubber oil, which can solve the problems of poor fluid viscosity of rubber oil, achieve good fluidity, enhance fluid viscosity, and apply to a wide temperature range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

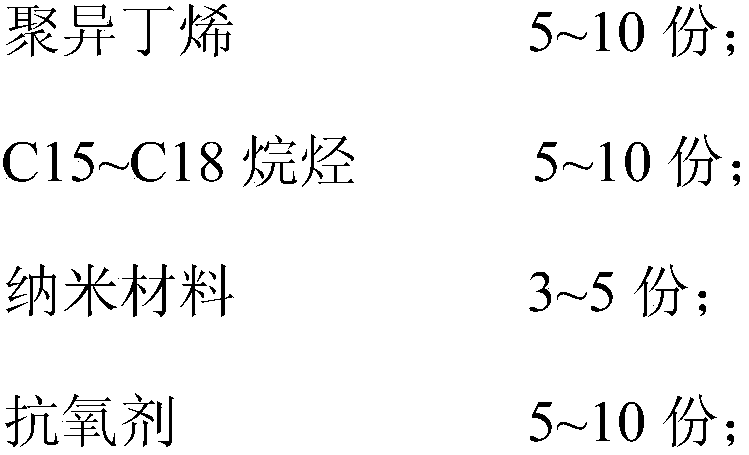

[0027] In this embodiment, the modified rubber oil additive includes the following components in parts by mass:

[0028]

[0029]

[0030] According to the preparation method of the above-mentioned modified rubber oil additive, the polyisobutene, heptadecane, nano silicon dioxide and antioxidant are stirred and mixed at 30° C. for 30 minutes according to the proportion to prepare the modified rubber oil additive.

[0031] The above-mentioned modified rubber oil includes rubber oil and the above-mentioned modified rubber oil additive, and the quality of the modified rubber oil additive is 0.5wt% of the rubber oil.

[0032] In the preparation method of the above-mentioned modified rubber oil, the rubber oil is put into a container for stirring, and the modified rubber oil additive is added and stirred to obtain the modified rubber oil.

Embodiment 2

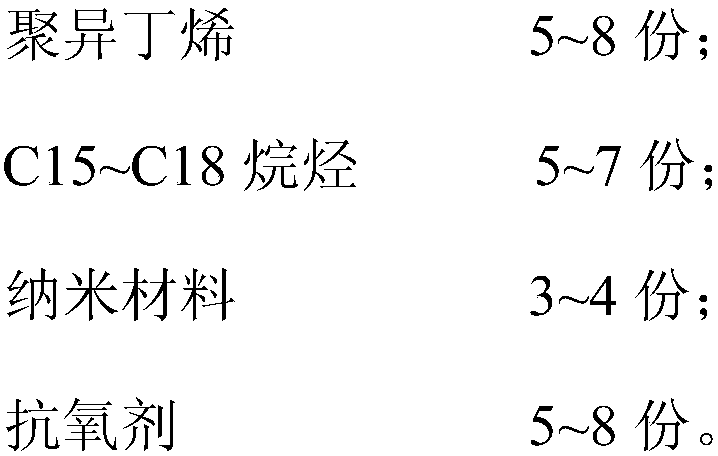

[0034] In this embodiment, the modified rubber oil additive includes the following components in parts by mass:

[0035]

[0036] The preparation method of the above-mentioned modified rubber oil additive, according to the proportion, mix the polyisobutylene, heptadecane, nano silicon dioxide and phosphorous acid antioxidant at 30°C for 40 minutes to prepare the modified rubber oil additive .

[0037] The above-mentioned modified rubber oil includes rubber oil and the above-mentioned modified rubber oil additive, and the quality of the modified rubber oil additive is 1 wt% of the rubber oil.

[0038] In the preparation method of the above-mentioned modified rubber oil, the rubber oil is put into a container for stirring, and the modified rubber oil additive is added and stirred to obtain the modified rubber oil.

Embodiment 3

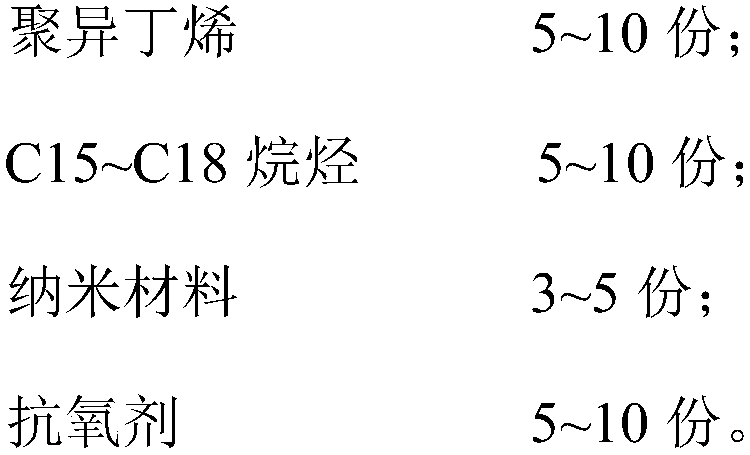

[0040] In this embodiment, the modified rubber oil additive includes the following components in parts by mass:

[0041]

[0042] According to the preparation method of the above-mentioned modified rubber oil additive, the polyisobutene, heptadecane, nano silicon dioxide and antioxidant are stirred and mixed at 30° C. for 30 minutes according to the proportion to prepare the modified rubber oil additive.

[0043] The above-mentioned modified rubber oil includes rubber oil and the above-mentioned modified rubber oil additive, and the quality of the modified rubber oil additive is 1.5wt% of the rubber oil.

[0044] In the preparation method of the above-mentioned modified rubber oil, the rubber oil is put into a container for stirring, and the modified rubber oil additive is added and stirred to obtain the modified rubber oil.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com