Bridging leak-stopping agent for fractured reservoir, and preparation method and application thereof

A kind of lost circulation agent and lost circulation agent technology, applied in the field of drilling lost circulation agent, can solve the problems of narrowing, oil and gas production decline, etc., and achieve the effect of preventing the damage of reservoir stress sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Base slurry: bentonite 5; NaCO 3 : 0.25; water: 100 (parts by weight).

[0022] Stoppage agent of the present invention:

[0023] Based on the total weight of the plugging agent, the weight percentage of each component is:

[0024] Quartz sand 14-20 mesh: 24%;

[0025] Calcium carbonate 40-60 mesh: 25%;

[0026] Calcium carbonate 80-150 mesh: 25%;

[0027] Calcium carbonate 400-600 mesh: 15%;

[0029] Acetate: 6%, length 1.8mm.

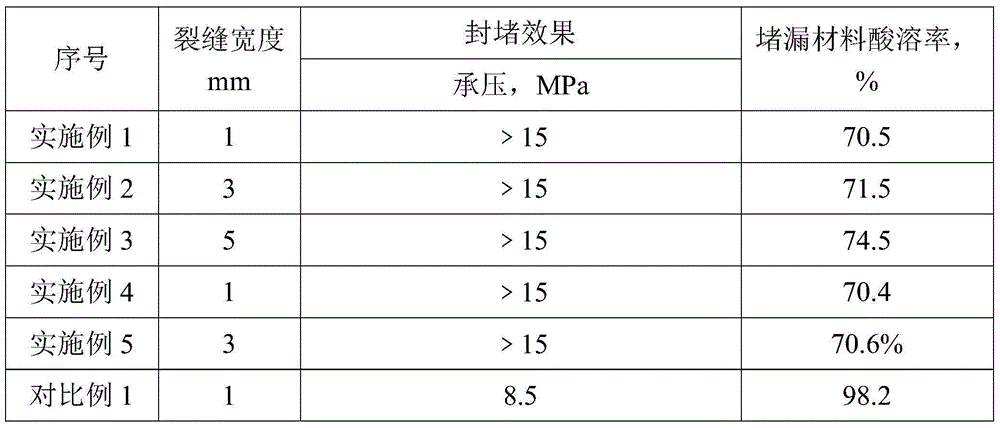

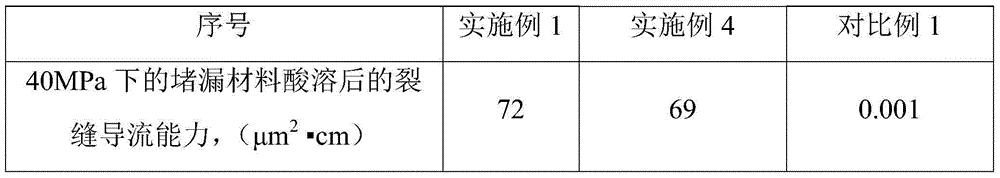

[0030] Mix the above components to get the mixed bridging plugging material, and test the plugging effect according to the conventional method. The plugging material can effectively plug artificial cracks with a width of 1mm, the pressure bearing capacity is greater than 15MPa, and the plugging agent is 15% The acid solubility rate under hydrochloric acid is 70.5%.

Embodiment 2

[0032] Base slurry: bentonite 5; NaCO 3 : 0.25; water: 100 (parts by weight).

[0033] Stoppage agent of the present invention:

[0034] Based on the total weight of the plugging agent, the weight percentage of each component is:

[0035] Quartz sand 6-8 mesh: 20%;

[0036] Calcium carbonate 16-30 mesh: 25%;

[0037] Calcium carbonate 60-120 mesh: 25%;

[0038] Calcium carbonate 400-600 mesh: 12%;

[0039] Asphalt powder: 8%;

[0040] Type II acetate: 10%, length 5mm.

[0041] Mix the above components to get the mixed bridging plugging material, and test the plugging effect according to the conventional method. The plugging material can effectively plug artificial cracks with a width of 3mm, the pressure bearing capacity is greater than 15MPa, and the plugging agent is 15% The acid solubility rate under hydrochloric acid is 71.5%.

Embodiment 3

[0043] Base slurry: bentonite 5; NaCO 3 : 0.25; water: 100 (parts by weight).

[0044] Stoppage agent of the present invention:

[0045] Based on the total weight of the plugging agent, the weight percentage of each component is:

[0046] Quartz sand 4-6 mesh: 18%;

[0047] Calcium carbonate 16-30 mesh: 25%;

[0048] Calcium carbonate 60-120 mesh: 25%;

[0049] Calcium carbonate 320-400 mesh: 13%;

[0050] Asphalt powder: 7%;

[0051] Tri-acetate: 12%, length 8mm.

[0052] Mix the above components to get a good bridging plugging material, and test the plugging effect according to the conventional method. The plugging material can effectively plug artificial cracks with a width of 5mm, the pressure bearing capacity is greater than 15MPa, and the plugging agent is 15% The acid solubility rate under hydrochloric acid is 74.5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pressure endurance | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com