A kind of energy-saving anti-wear lubricating oil and its production process and use method

A production process and lubricating oil technology, applied in the field of lubricating oil, can solve problems such as large changes in friction coefficient, and achieve the effects of stable idle speed, reduced noise and small wear and tear.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

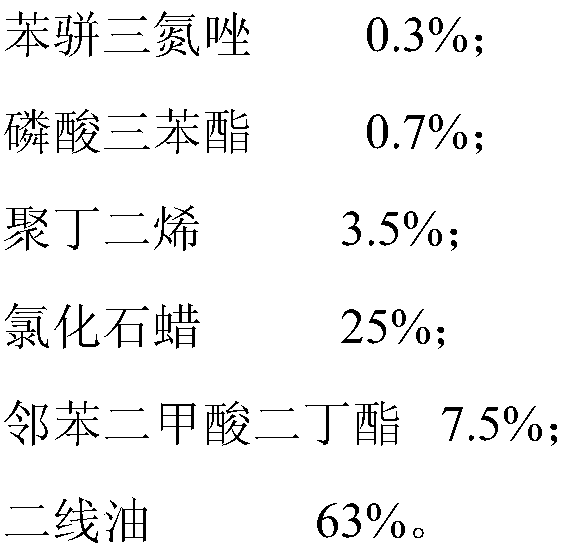

[0060] Example 1 An energy-saving and anti-wear lubricant and its production process

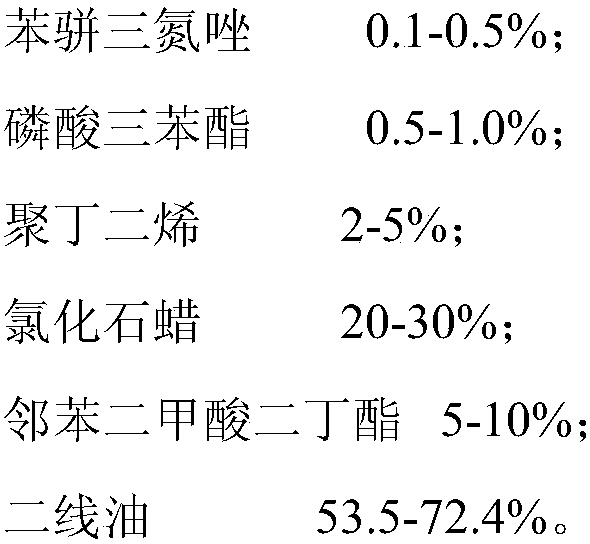

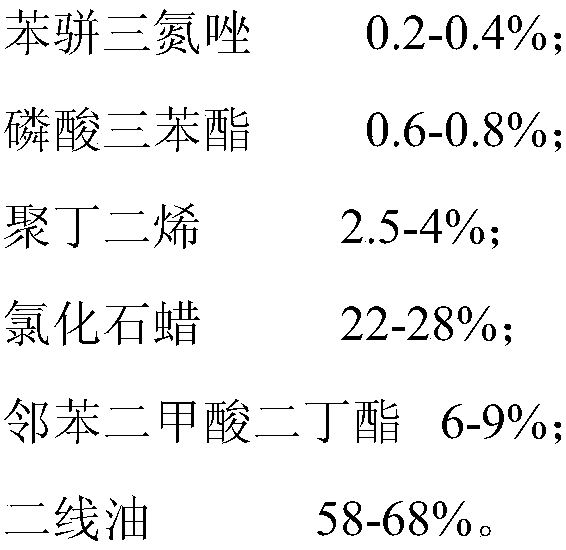

[0061] Energy-saving anti-wear lubricating oil is composed of the following raw materials by mass percentage:

[0062] Benzotriazole 0.3%;

[0063] Triphenyl phosphate 0.7%;

[0064] Polybutadiene 3.5%;

[0065] Chlorinated paraffin 25%;

[0066] Dibutyl phthalate 7.5%;

[0067] Second line oil 63%.

[0068] The production process of the above-mentioned energy-saving and anti-wear lubricating oil is as follows:

[0069] (1) Firstly, take 60% (mass fraction) of the total amount of second-line oil and add it to No. 1 container, which is a stainless steel container with a stirrer;

[0070] (2) Weigh chlorinated paraffin and polybutadiene, pour them into No. 1 container successively, and stir;

[0071] (3) Pour dibutyl phthalate into container No. 1 and continue stirring;

[0072] (4) Weigh 10% (mass fraction) of the second-line oil in the total amount of the second-line oil, put it in N...

Embodiment 2

[0075] Example 2 An energy-saving and anti-wear lubricant and its production process

[0076] Energy-saving anti-wear lubricating oil is composed of the following raw materials by mass percentage:

[0077] Benzotriazole 0.15%;

[0078] Triphenyl phosphate 0.8%;

[0079] Polybutadiene 4%;

[0080] Chlorinated paraffin 21%;

[0081] Dibutyl phthalate 6%;

[0082] Second-line oil 68.05%.

[0083] The production process of the above-mentioned energy-saving and anti-wear lubricating oil is as follows:

[0084] (1) Firstly, take 60% (mass fraction) of the total amount of second-line oil and add it to No. 1 container, which is a stainless steel container with a stirrer;

[0085] (2) Weigh chlorinated paraffin and polybutadiene, pour them into No. 1 container successively, and stir;

[0086] (3) Pour dibutyl phthalate into container No. 1 and continue stirring;

[0087] (4) Weigh 10% (mass fraction) of the second-line oil in the total amount of the second-line oil, put it in N...

Embodiment 3

[0090] Example 3 An energy-saving and anti-wear lubricant and its production process

[0091] Energy-saving anti-wear lubricating oil is composed of the following raw materials by mass percentage:

[0092] Benzotriazole 0.45%;

[0093] Triphenyl phosphate 0.8%;

[0094] Polybutadiene 5%;

[0095] Chlorinated paraffin 28%;

[0096] Dibutyl phthalate 6%;

[0097] Second line oil 59.75%.

[0098] The production process of the above-mentioned energy-saving and anti-wear lubricating oil is as follows:

[0099] (1) Firstly, take 60% (mass fraction) of the total amount of second-line oil and add it to No. 1 container, which is a stainless steel container with a stirrer;

[0100] (2) Weigh chlorinated paraffin and polybutadiene, pour them into No. 1 container successively, and stir;

[0101] (3) Pour dibutyl phthalate into container No. 1 and continue stirring;

[0102] (4) Weigh 10% (mass fraction) of the second-line oil in the total amount of the second-line oil, put it in N...

PUM

| Property | Measurement | Unit |

|---|---|---|

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com