High-vacuum water quenching solid solution furnace system

A solid solution furnace and high vacuum technology, used in furnaces, heat treatment furnaces, furnace types, etc., can solve the problems of poor treatment effect, short life of heating chamber, transition loss, etc., to ensure the quality of solid solution, high vacuum, The effect of improving component life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

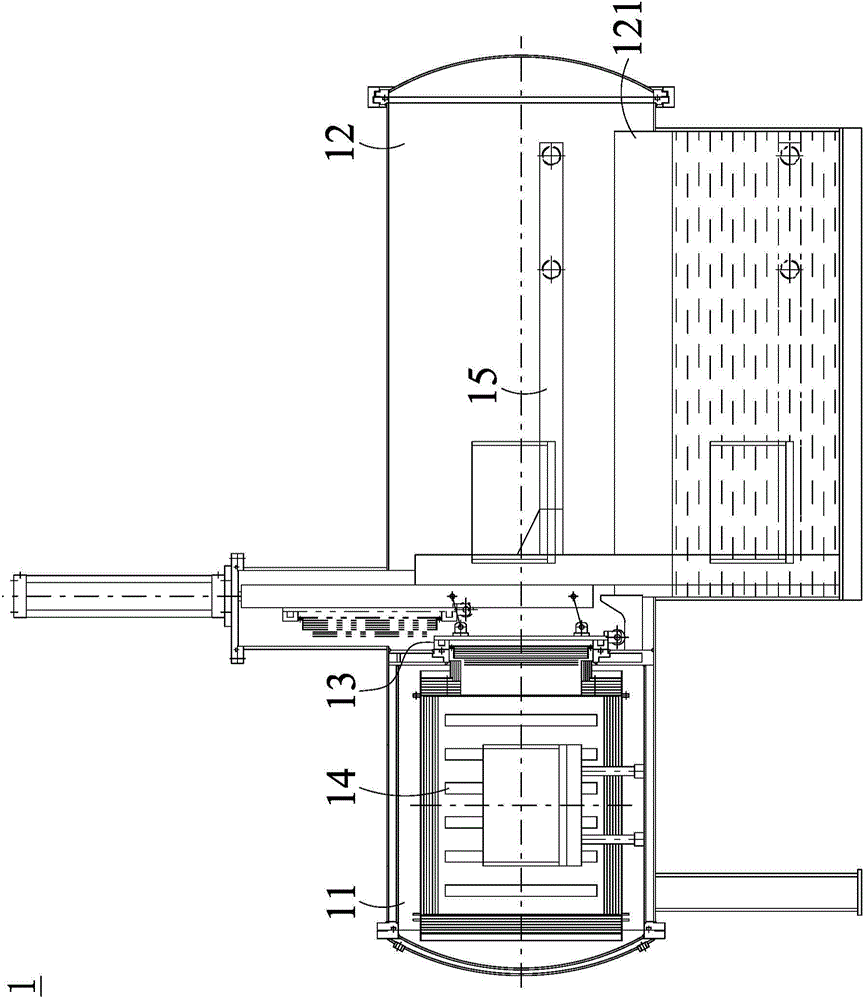

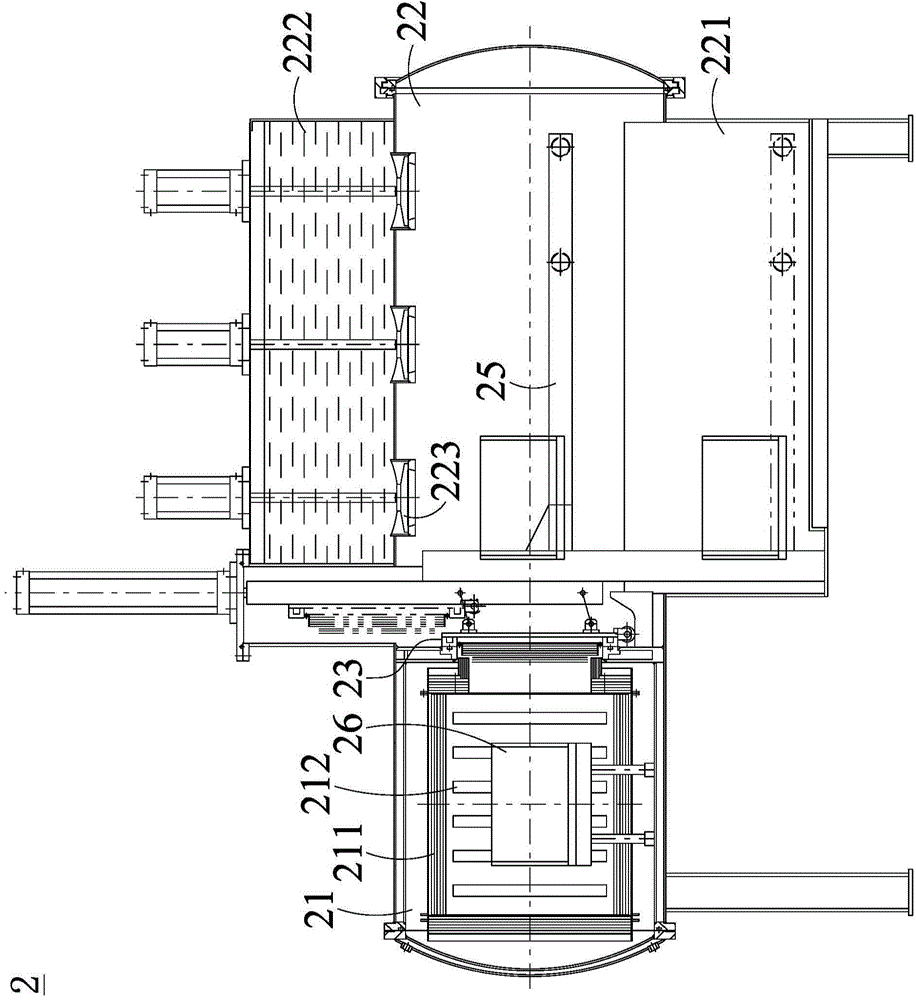

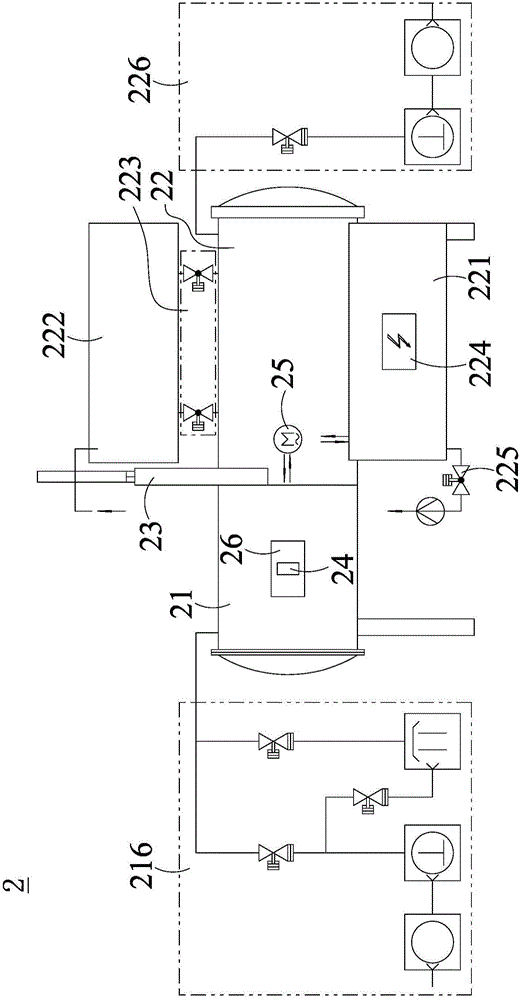

[0030] Typical embodiments embodying the features and advantages of the present invention will be described in detail in the following description. It should be understood that the present invention is capable of various changes in different embodiments without departing from the scope of the present invention, and that the description and drawings therein are illustrative in nature and not limiting. this invention.

[0031] The high-vacuum water quenching solid solution furnace system of the present invention includes a heating chamber and a cooling chamber that can be switched on and off each other. A cooling water tank and a water storage tank are arranged in the cooling chamber. Inject water in one direction, and when the cooling water tank is not cooling the workpiece, drain the cooling water and dry it. Through this structure, it can be realized that when the cooling chamber and the heating chamber are connected, no water vapor is generated in the cooling chamber, there...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com