A thread winding device used for textile

A technology of winding device and slider, which is applied to textiles and papermaking, spinning machines, spinning machines with continuous winding, etc. It can solve the problems of high cost of winding, large damage to textile threads, time-consuming and labor-intensive use, etc., and achieves The effect of protecting textile threads

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

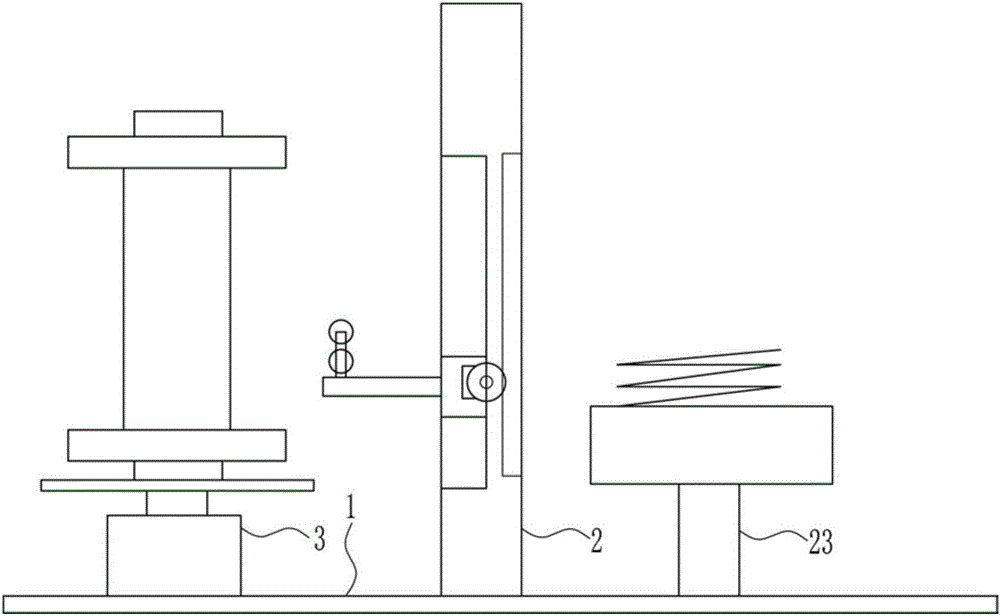

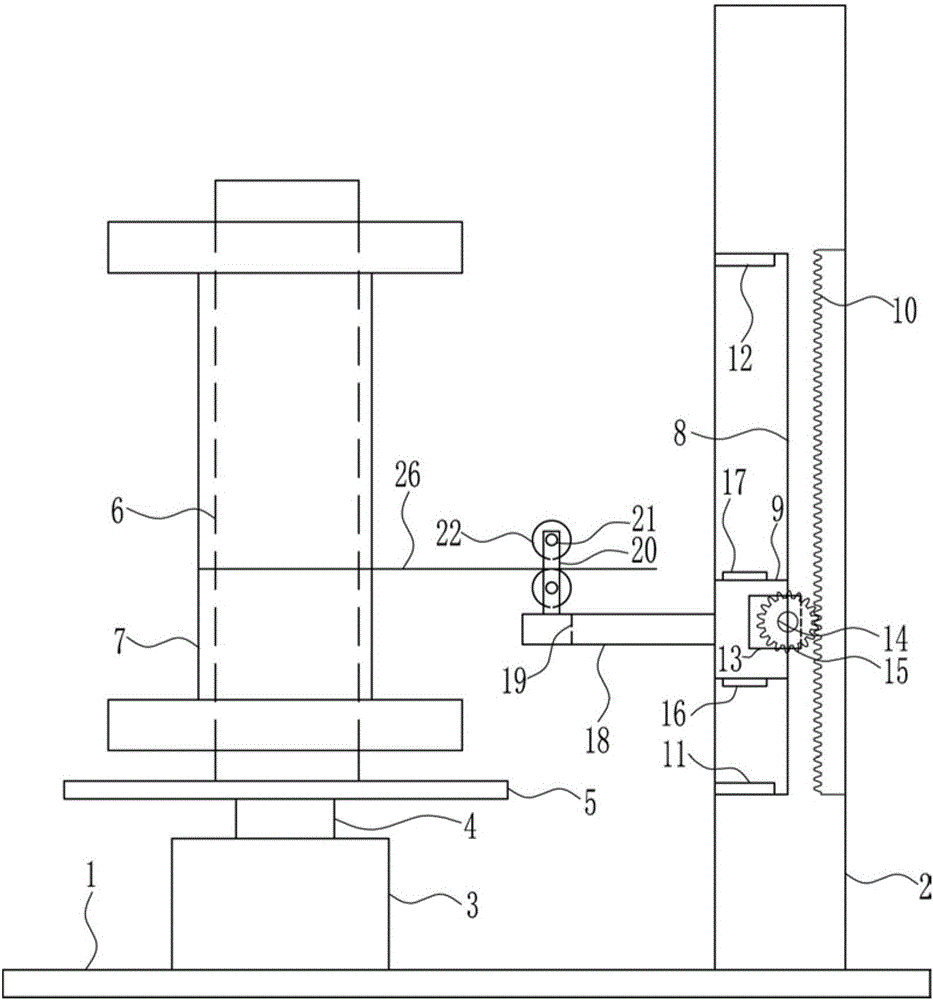

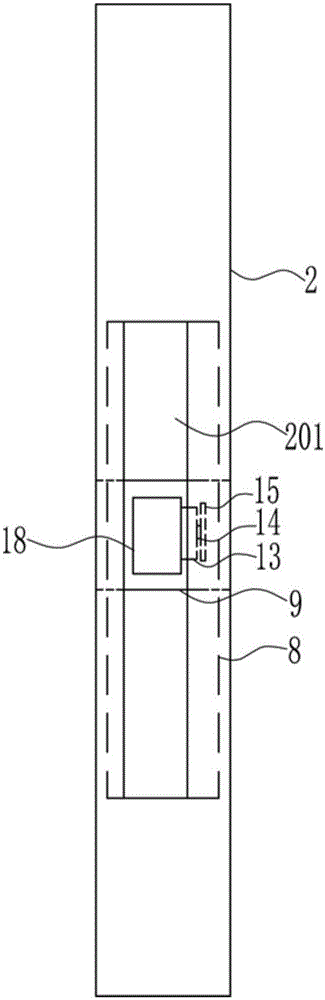

[0031] A kind of winding device for weaving, such as Figure 1-6 As shown, it includes a bottom plate 1, a first bracket 2, a first motor 3, a first rotating shaft 4, a tray 5, a first fixing sleeve 6, a bobbin 7, a first slide rail 8, a first slider 9, and a rack 10. First travel switch 11, second travel switch 12, second motor 13, second shaft 14, gear 15, third travel switch 16, fourth travel switch 17, support rod 18, support seat 19, wheel bracket 20 , the first connecting shaft 21, guide wheel 22, support foot 23, support platform 24, textile thread 25 and textile thread 26, the first bracket 2 is installed in the upper middle part of the bottom plate 1, and the first motor 3 is installed in the left side on the bottom plate 1 , the first motor 3 is located on the right side of the first support 2, and the support foot 23 is installed on the right side of the bottom plate 1, and the support foot 23 is located on the right side of the first support 2, and the upper end of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com