A raising processing device for raised fabric

A processing device, a technology for fleece fabrics, applied in the direction of fabrics, fabric surface trimming, heating/cooling fabrics, etc., which can solve the problems of reduced commodity properties, downfall of fleece, knotted fleece, etc., to achieve excellent commodity properties, uniform temperature, elimination of Effects of undesirable phenomena

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0066] The present invention will be further described below in conjunction with accompanying drawing, and the structure and principle of this device are very clear to those skilled in the art. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

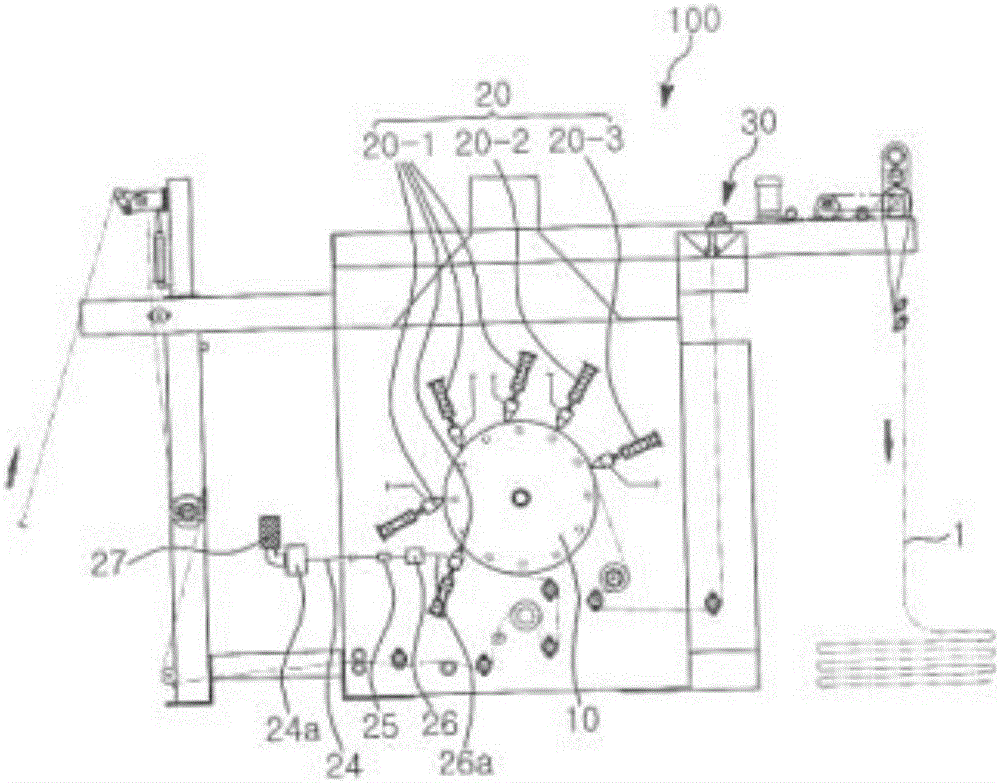

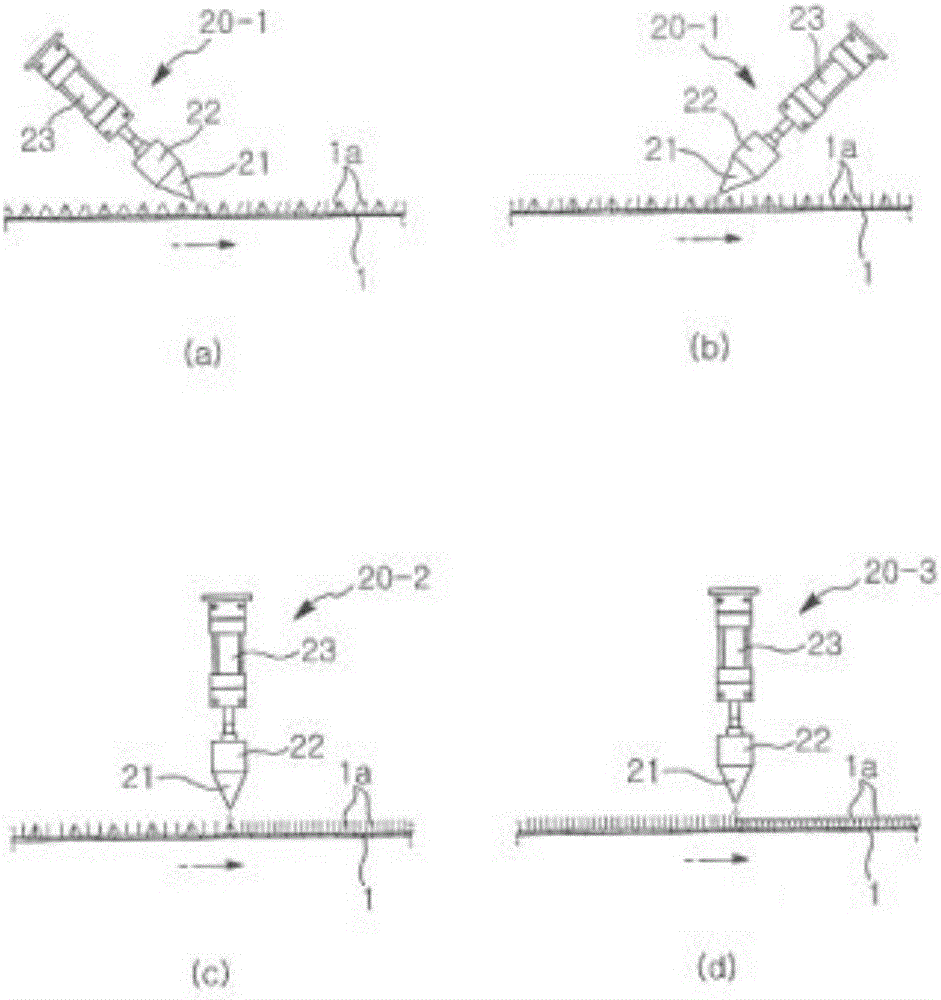

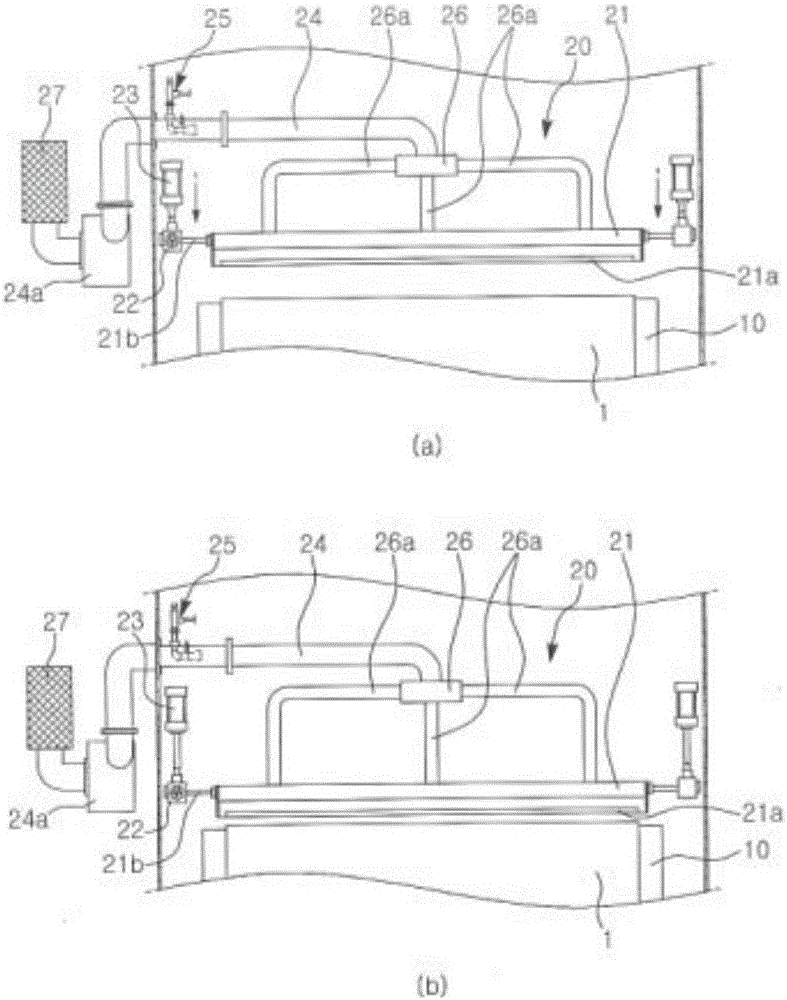

[0067] Such as Figure 1 to Figure 6 Shown in, the described pile processing device (100) of the pile fabric of the embodiment of the present invention comprises guide roller (10), hot air means (20) and cold air means (30), and described guide roller uses In order to guide and transfer the pile fabric (1), the hot air means sprays hot air to the pile (1a), and the cold air means sprays cold air to the pile (1a) passing through the hot air means (20).

[0068] The fleece (1a) of the fleece fabric (1) is made of polyester material that deforms when heated.

[0069] The pile processing device (100) of the pile fabric also includes she...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap