Composite self-insulation brick

A technology of self-insulation and bricks, which is applied in the direction of building materials, can solve the problems of inability to solve the effective stability of the connection between the upper and lower layers, the reduction of the insulation effect of the composite self-insulation block, and the low cohesion of the composite self-insulation block. Achieve the effect of light weight, simple structure, and solve the problem of poor bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

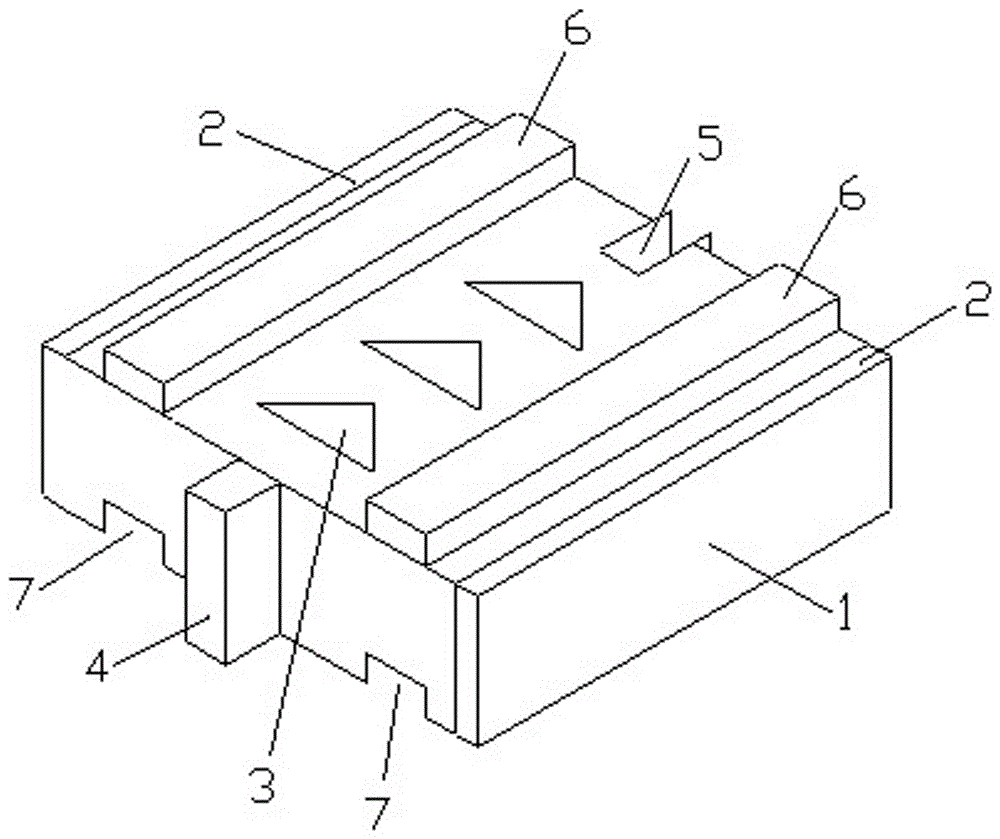

[0012] Such as figure 1 As shown, a composite self-insulating brick includes a brick body 1. The middle of the brick body 1 is provided with a triangular through hole 3, both ends of the brick body 1 are provided with heat preservation holes 2, and the heat preservation holes 2 are filled with heat preservation materials , One end of the brick body 1 is provided with an end protrusion 4, and the other end of the brick body 1 is provided with an end groove 5 that is matched with the end protrusion 4. The depth of the end groove 5 is greater than the length of the end protrusion 4, and the end groove 5 The outer edge of the brick body 1 is higher than the highest point of the end of the brick body 1 on the same side. Both sides of the upper side of the brick body 1 are provided with top protrusions 6, and both sides of the lower side of the brick body 1 are equipped with top protrusions 6 The depth of the top groove 7 is greater than the height of the top protrusion 6. The trian...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com