Sealing device for lifting and lowering SAGD well temperature-measuring cable under pressure

A technology of sealing device and cable belt, which is applied in the directions of sealing/isolation, wellbore/well parts, earthwork drilling and production, etc. It can solve the problems that affect the production cycle of production oil wells, failure of production wells, and corrosion of metals, etc., and achieve improvement. The effect of gas injection time limit, shortening construction period and reducing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

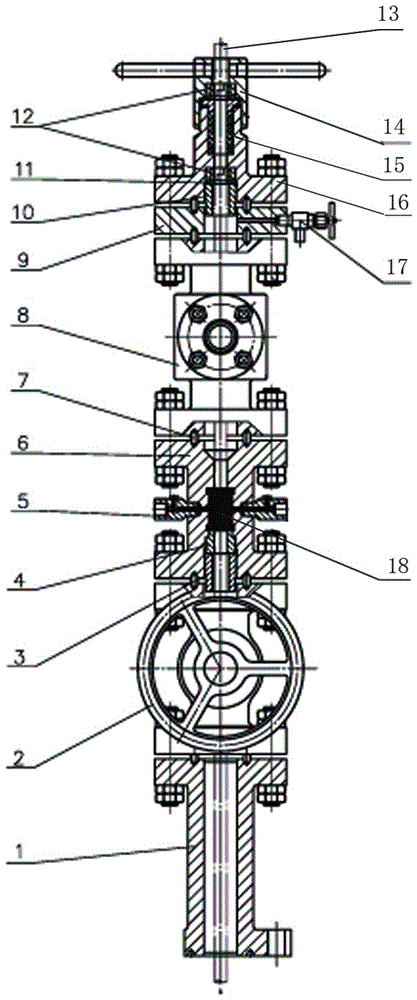

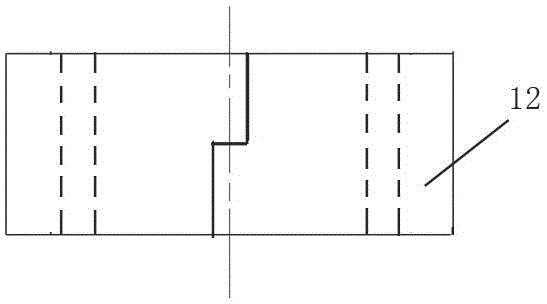

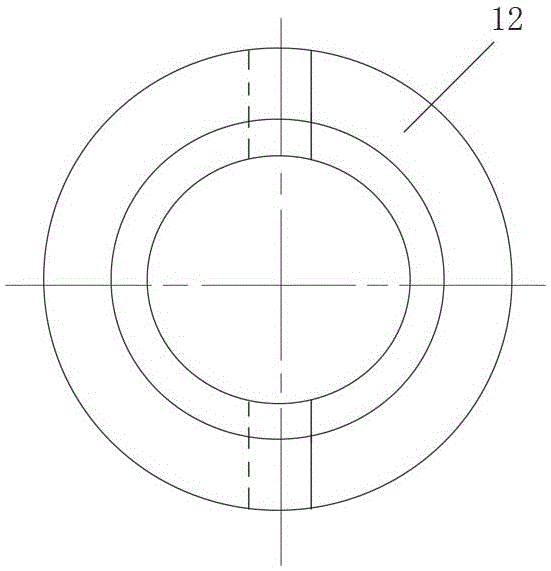

[0034] Such as figure 1 , 2 As shown in , 3, it is used for the sealing device of the temperature measuring cable in SAGD well, including pressure relief valve, thermal recovery gate valve, hydraulic blowout preventer and grease injection valve, and the flange at one end matches the well head. The flange at the other end of the flange is fixedly connected with the flange at one end of the thermal recovery gate valve, the flange at the other end of the thermal recovery gate valve is fixedly connected with the flange at one end of the grease injection sealer, and the flange at the other end of the grease injection sealer is connected with the hydraulic valve One end flange of the blowout preventer is fixedly connected, the other end flange of the hydraulic blowout preventer is fixedly connected with the pressure relief flange in series and one end flange of the packing box, and the other end of the packing box is threaded with the packing gland Connection, I-shaped flange and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com