In-situ oil extraction method for oil shale

An oil shale, oil and gas technology, applied in the field of oil shale in-situ exploitation of oil or natural gas, can solve the problems of low utilization rate of heating energy and energy waste, and achieve the effects of shortening heating time, improving utilization efficiency and saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with accompanying drawing.

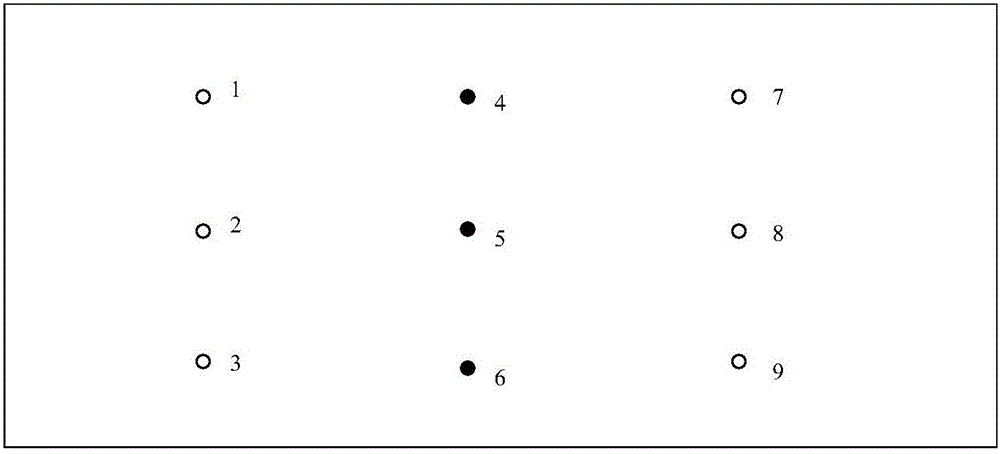

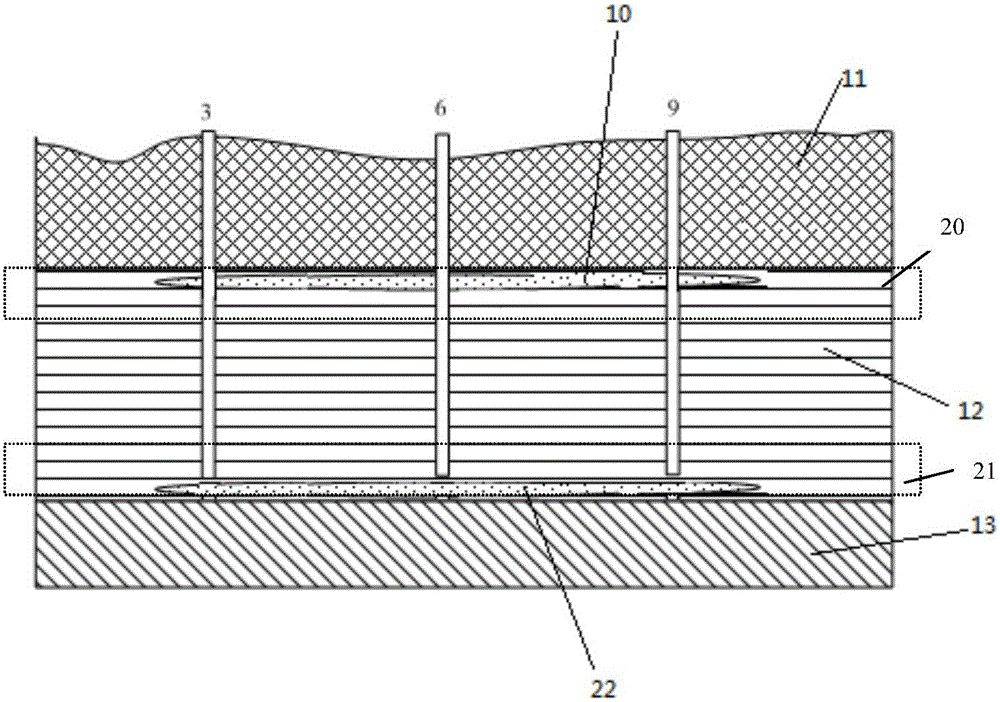

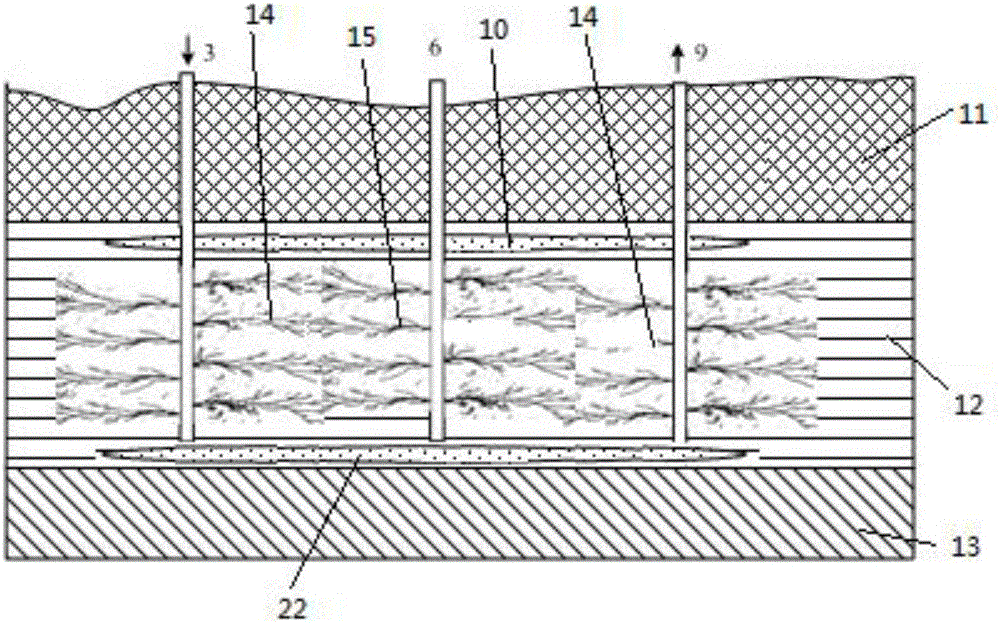

[0022] figure 1 It schematically shows the way of arranging heater wells, gas injection wells and production wells according to the method of the present invention. like figure 1 As shown, heater wells 4, 5, and 6 are arranged in the middle, while gas injection wells 1, 2, and 3 are arranged on one side of heater wells 4, 5, and 6, and production wells 7, 8, and 9 are arranged at heater wells 4, 5. , the other side of 6. In this way, when the formation is heated through the heater wells 4, 5, and 6 in the later stage, the heat will spread around the heater well as the center of the circle, and when the heat reaches the gas injection well, it will also reach the production well, thereby greatly improving the heat utilization rate And improve the construction efficiency.

[0023] The method according to the present invention will be described in detail below by taking the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com