A hydraulic staggered depressurization and enhanced permeability drainage method for coal seam gas

A coal seam gas and hydraulic fracturing technology, which is applied in the direction of gas discharge, mining fluid, mining equipment, etc., to achieve the effects of preventing stress concentration effects, saving workload, and improving operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

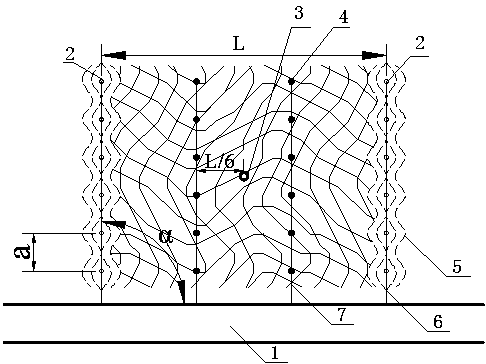

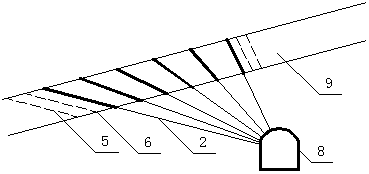

[0026] The hydraulic staggered pressure relief and anti-permeability drainage method for coal seam gas of the present invention, such as Figure 1-2 As shown, the specific steps are as follows:

[0027] (1) Use the integrated drilling and punching drill bit to drill from the floor drainage roadway 1 at the construction azimuth α=90° to the coal seam 9, discharge the powder under hydrostatic pressure, and drill through the coal seam 9 and enter the coal seam roof for 0.5m;

[0028] (2) Use high-pressure water as the medium and use hydraulic punching technology to punch the hole in step (1) from the bottom of the hole to the outside to form a hydraulic punching hole 2. The punching pressure is adjusted according to the coal seam firmness coefficient f It is 12f Mpa, and the amount of punched coal per meter of coal hole is not less than 1t, forming holes to relieve the pressure of the coal body;

[0029] Carry out sealing and continuous pumping to the hydraulic punching hole 2; ...

Embodiment 2

[0037] The hydraulic staggered pressure relief and anti-permeability drainage method for coal seam gas of the present invention, such as Figure 1-2 As shown, the specific steps are as follows:

[0038] (1) Use the integrated drilling and punching drill bit to drill from the floor drainage roadway 1 at the construction azimuth α=90° to the coal seam 9, discharge the powder under hydrostatic pressure, and drill through the coal seam 9 and enter the coal seam roof for 0.5m;

[0039] (2) Use high-pressure water as the medium and use hydraulic punching technology to punch the hole in step (1) from the bottom of the hole to the outside to form a hydraulic punching hole 2. The punching pressure is adjusted according to the coal seam firmness coefficient f It is 16f MPa, and the amount of punched coal per meter of coal hole is not less than 1t, forming holes to relieve the pressure of the coal body;

[0040] Carry out sealing and continuous pumping to the hydraulic punching hole 2; ...

Embodiment 3

[0048] The hydraulic staggered pressure relief and anti-permeability drainage method for coal seam gas of the present invention, such as Figure 1-2 As shown, the specific steps are as follows:

[0049] (1) Use the integrated drilling and punching drill bit to drill from the floor drainage roadway 1 at the construction azimuth α=90° to the coal seam 9, discharge the powder under hydrostatic pressure, and drill through the coal seam 9 and enter the coal seam roof for 0.5m;

[0050] (2) Use high-pressure water as the medium and use hydraulic punching technology to punch the hole in step (1) from the bottom of the hole to the outside to form a hydraulic punching hole 2. The punching pressure is adjusted according to the coal seam firmness coefficient f It is 20f MPa, and the amount of coal punched per meter of coal hole is not less than 1t, forming holes to relieve the pressure of the coal body;

[0051] Carry out sealing and continuous pumping to the hydraulic punching hole 2; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com