Device capable of automatically adjusting rigidity of flexible blade of wind turbine

A technology of automatic adjustment and blade stiffness, which is applied to wind turbines, wind turbines, engines, etc. in the same direction as the wind, can solve the problems of blade fatigue damage, blade bending and torsion fracture, etc., and achieve the effect of changing rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

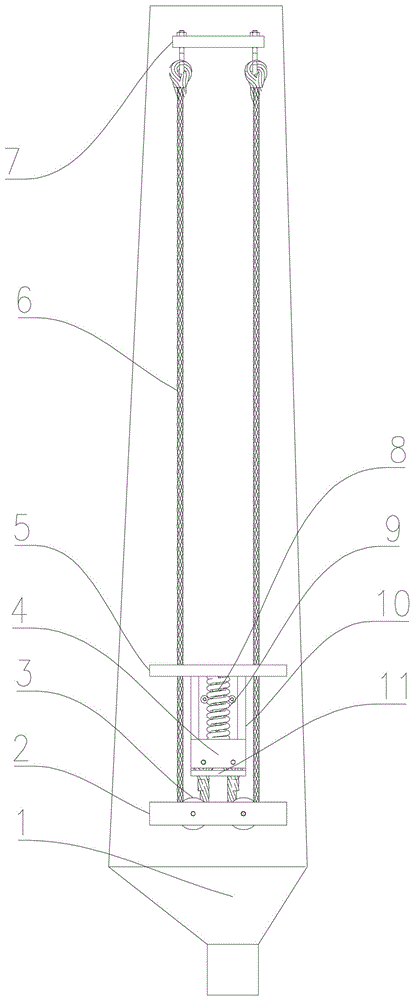

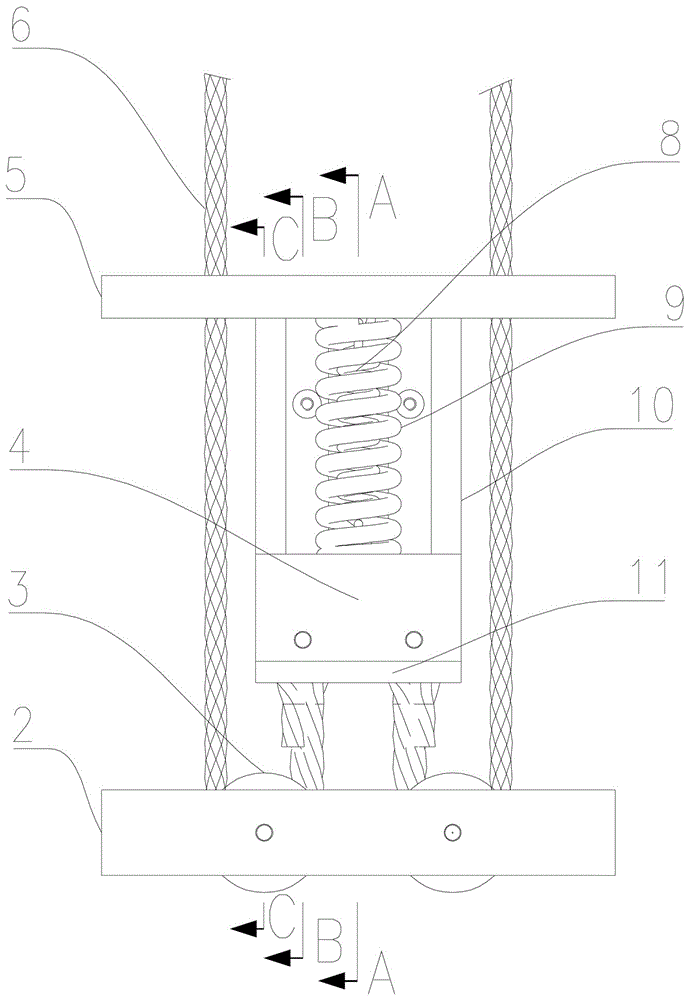

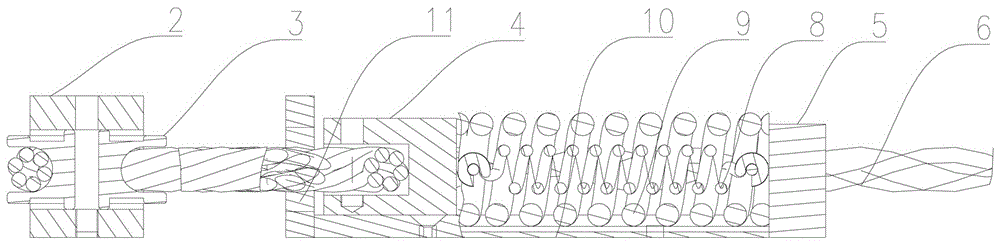

[0025] Embodiment 1, refer to Figure 1 to Figure 3 , the present invention includes a support block 2, a fixed pulley 3, an inertia block 4, a front end fixed block 5, a steel wire rope 6, a tail end fixed block 7, a tension spring 8, a compression spring 9 and a linear guide rail 10; the support block 2, the front end The fixed block 5 and the tail end fixed block 7 are respectively arranged side by side on the same side of the flexible blade 1 from inside to outside, and a linear guide rail 10 is fixed on the flexible blade 1 between the support block 2 and the front end fixed block 5, The inertia block 4 is installed on the linear guide rail 10; two fixed pulleys 3 are arranged on the support block 2; one end of the tension spring 8 and the compression spring 9 are respectively connected with the front end fixed block 5, and the other ends are respectively connected with the fixed block 5 installed on the straight line The inertia block 4 on the guide rail 10 is connected;...

Embodiment 2

[0026] Embodiment 2, refer to Figure 1 to Figure 3 , the support block 2 of the present invention is installed at a position close to the root of the flexible blade 1, and the front end fixed block 5 is installed on one side of the support block 2, and the front end fixed block 5 is connected and fixed with one end of the linear guide rail 10; the support block 2, the front end Both the fixed block 5 and the linear guide rail 10 are respectively fixed on the flexible blade 1 . The rest are combined with another arbitrary embodiment of the present invention or two or more embodiments.

Embodiment 3

[0027] Embodiment 3, refer to Figure 1 to Figure 3, the tail end fixing block 7 of the present invention is installed on the outer end of the flexible blade 1 near the tail end of the blade tip, the bottom of the tail end fixing block 7 is fixed on the flexible blade 1, and a filling material is arranged on the outer periphery of the tail end fixing block 7 to seal it The surrounding is fastened so that it is integrated with the blade tip part of the flexible blade 1 to prevent long-term erosion and cause the product to fall off. The rest are combined with another arbitrary embodiment of the present invention or two or more embodiments.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com