Gear shifting executor

A gear shift actuator and actuator technology, applied to components with teeth, belts/chains/gears, mechanical equipment, etc., can solve the problems of inability to accurately control gear shift actuators, occupy a large space, and provide real-time feedback , to achieve stable and reliable operation of equipment, reduce vibration and noise, and achieve stable and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Embodiments of the present invention are described in detail below:

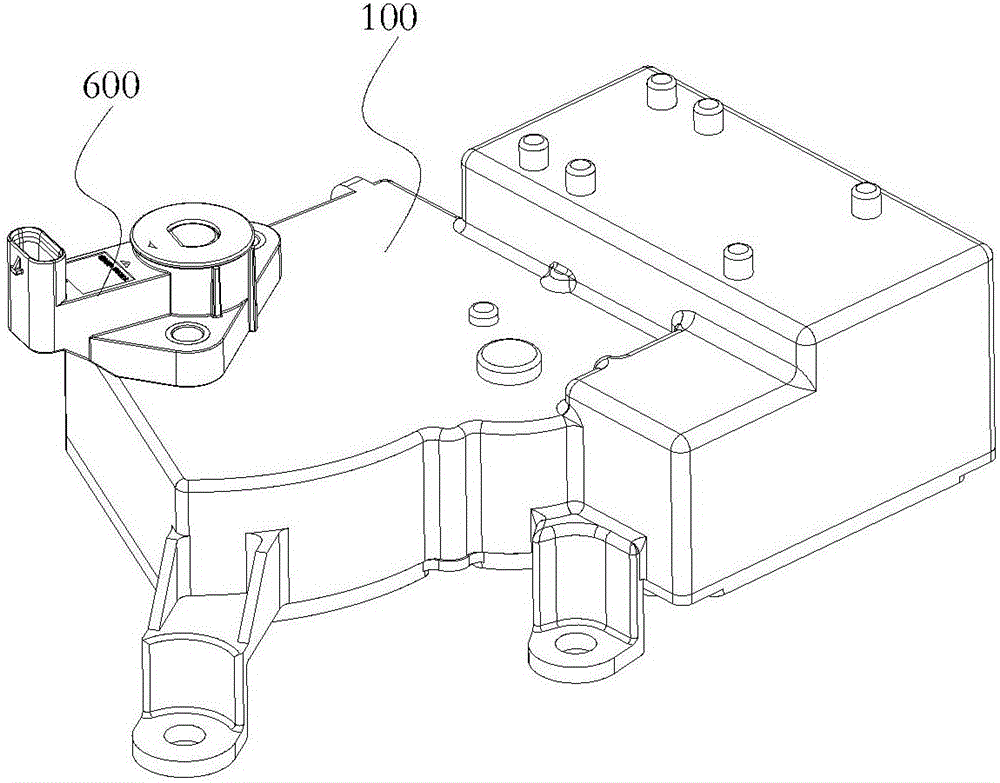

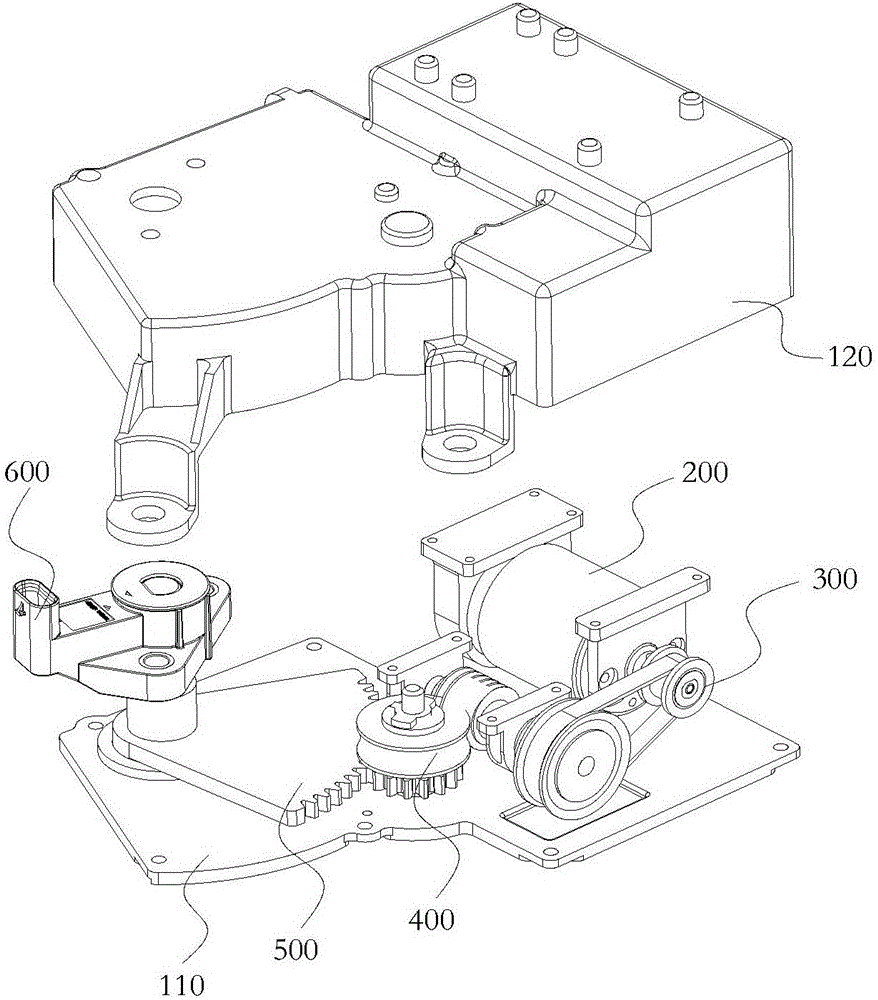

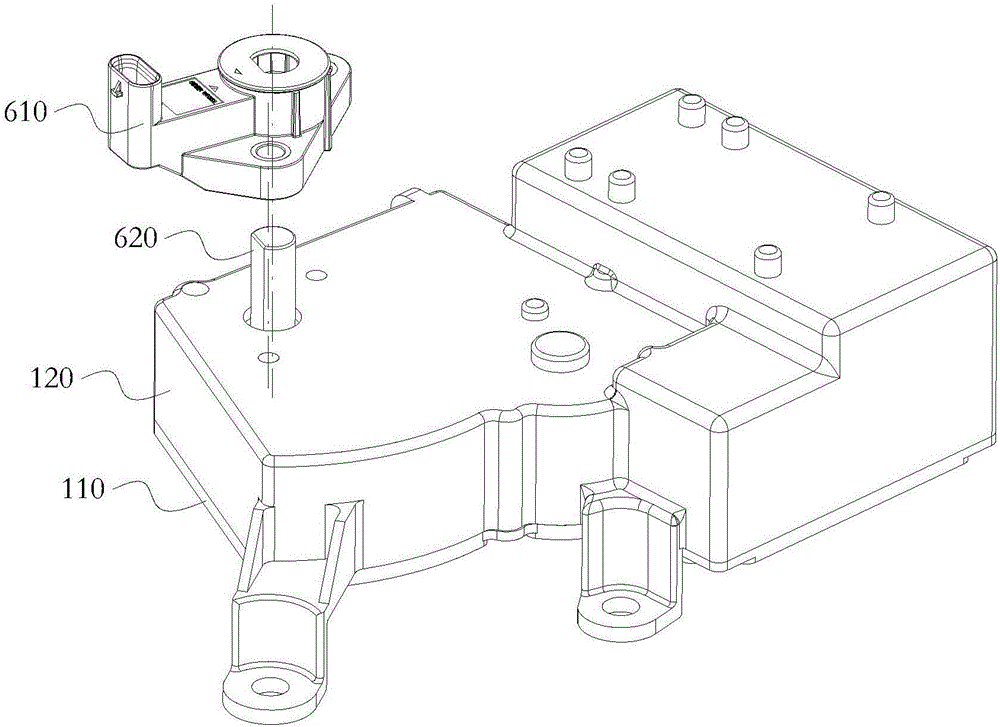

[0039] Such as Figure 1 to Figure 5 As shown, a shift actuator includes an actuator housing 100, a drive mechanism 200 disposed in the actuator housing 100, a transmission structure connected to the drive mechanism 200 and connected to the transmission shift shaft 10 , and a position detection mechanism 600 arranged on the actuator housing 100 and connected with the transmission structure. The driving mechanism 200 drives the transmission structure to run, thereby driving the transmission shift shaft 10 connected to the transmission structure to rotate, so as to realize the shifting function. During the shifting process, the rotational position of the shift shaft 10 can be detected in real time by the position detection mechanism 600 to identify the current gear position in real time, and the real-time situation can be fed back to the GSM (shift control module), and the controller can perform real-t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com