Suspension-fence-type top-feeding waste incineration apparatus

A waste incineration and fencing technology, applied to incinerators, combustion methods, combustion types, etc., can solve problems such as poor fire environment, slow incineration speed, and heavy pollution from low-temperature incineration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

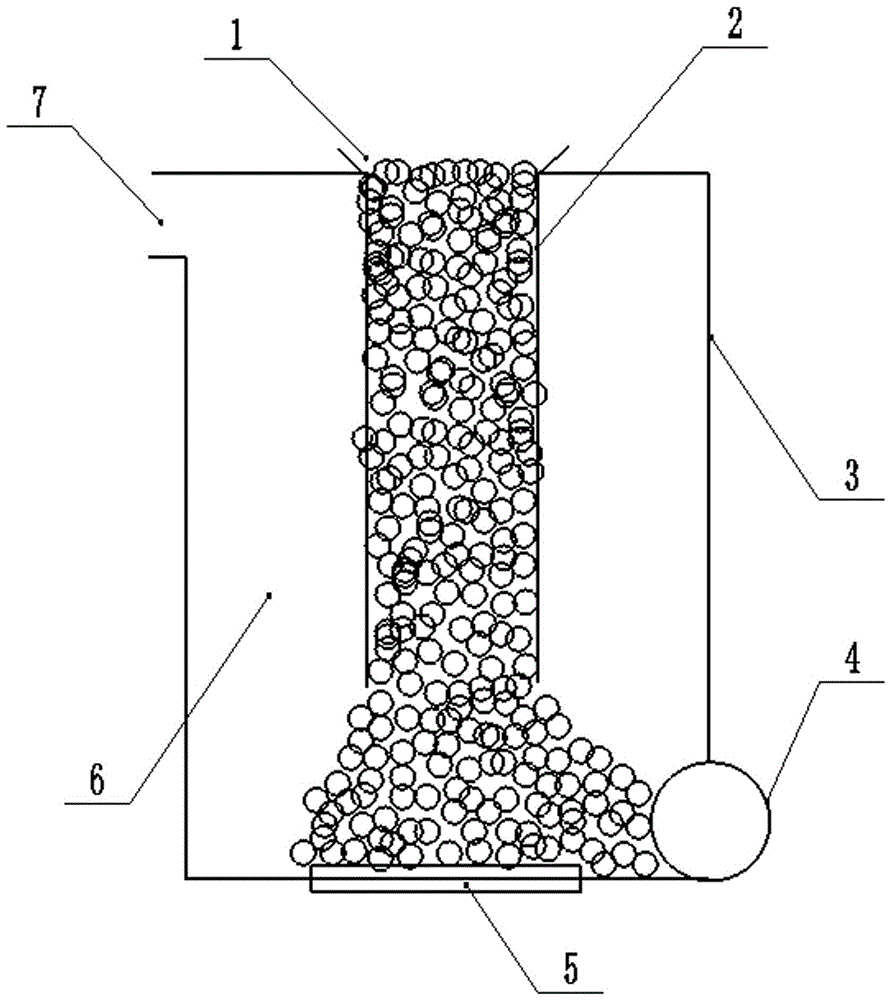

[0014] A hanging fence-type upper-feeding garbage incineration device, including a feed inlet 1, a furnace 6, a furnace wall 3, a suspension fence 2, a smoke exhaust port 7, an ash discharge port 5, and an ignition door 4. The suspension fence 2 is designed At the top of the furnace 6, the lower end of the suspension fence 2 is not in contact with the bottom of the furnace 6, the feed inlet 1 is located directly above the suspension fence 2 and connected with the suspension fence 2, and the ash discharge port 5 is located at the bottom of the furnace 6. The smoke port 7 is located above the furnace wall 3 , and the ignition door 4 is located below the furnace wall 3 .

[0015] The suspension fence 2 is connected by vertically arranged metal bars to form a circle-shaped fence with even intervals.

[0016] The metal strip can withstand a temperature above 1000°C.

[0017] The ash outlet 5 is located at the bottom of the hearth 6 directly below the suspension fence 2 .

[0018]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com