Weldless lightweight water heater inner container product and manufacture method thereof

A water heater liner and manufacturing method technology, applied in the field of sheet metal forming, can solve the problems not involved in the lightweight design of products, and achieve the effects of reducing the risk of water leakage, reducing costs, and omitting stamping and welding processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

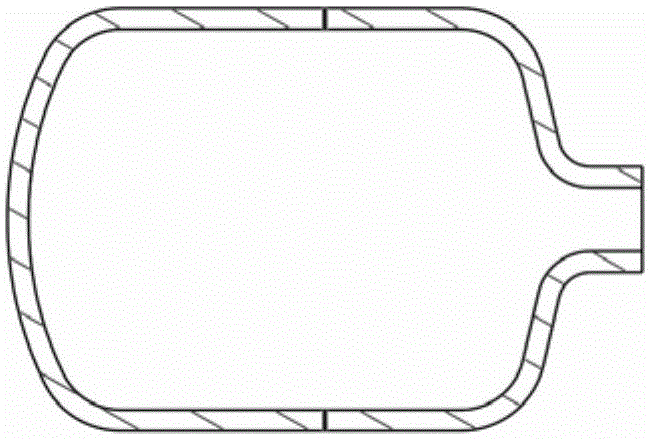

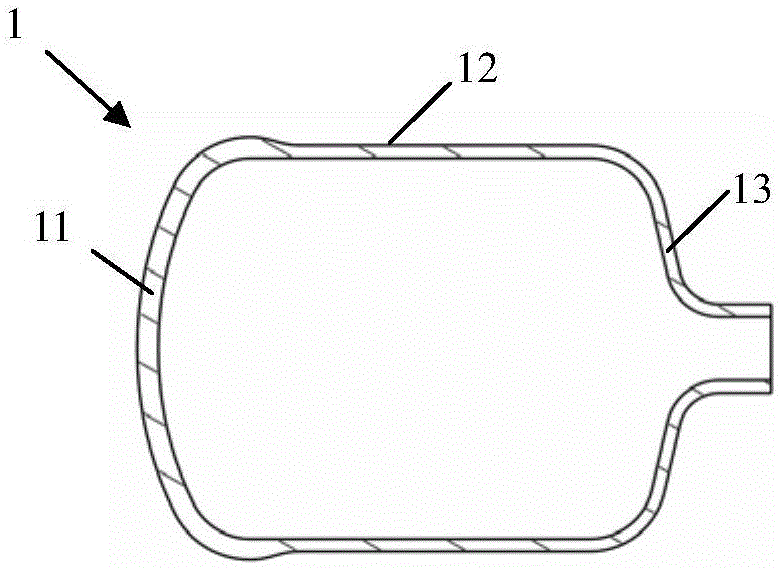

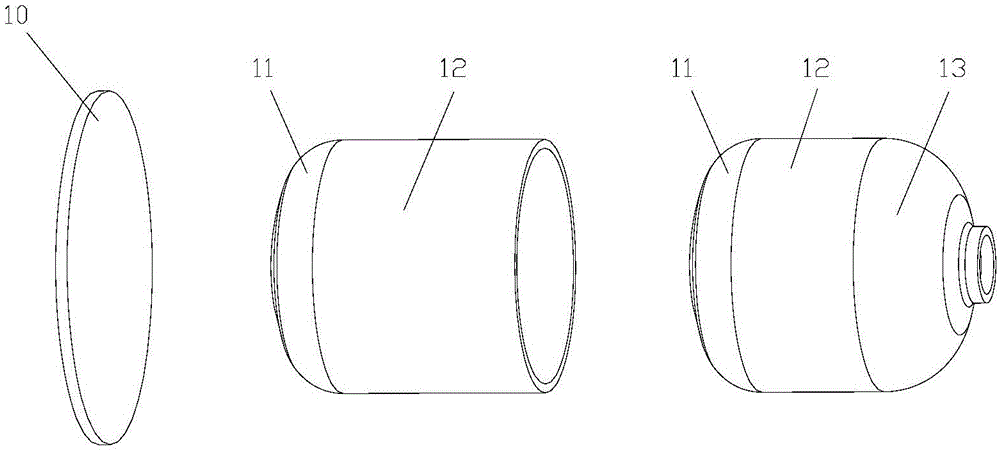

[0031] join Figure 4 , firstly, put the circular sheet close to the tail top of the mandrel in the shape of an arc-shaped barrel bottom, the rotary wheel starts from the center of the circular sheet, and the forming track of the rotary wheel is with a diameter of The circular arc with a chord height of 87.5mm begins to form the straight wall section, and the rotary wheel gradually presses the circular sheet to the press rod, and the forming track is a straight line with a length of about 530mm. During the process, the reduction amount is controlled according to the requirements to obtain a thinning barrel At this point, the circular sheet material has been formed into a straight-walled cylindrical piece with a barrel bottom shape at the tail; then, the barrel body is clamped by a clamp, and the other open end is spin-formed, and the spinning wheel forming track is a The circular arc forms a head with an opening, and finally obtains a lightweight water heater liner without we...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com