Test device and test method for critical seepage air pressure of soil in saturated strata under three-dimensional stress

A technology of air pressure test and three-dimensional stress, applied in measurement devices, surface/boundary effects, permeability/surface area analysis, etc., can solve the problems of inaccuracy, reduce construction speed, affect construction progress, etc. Construction safety, providing the effect of construction progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below in conjunction with specific embodiments.

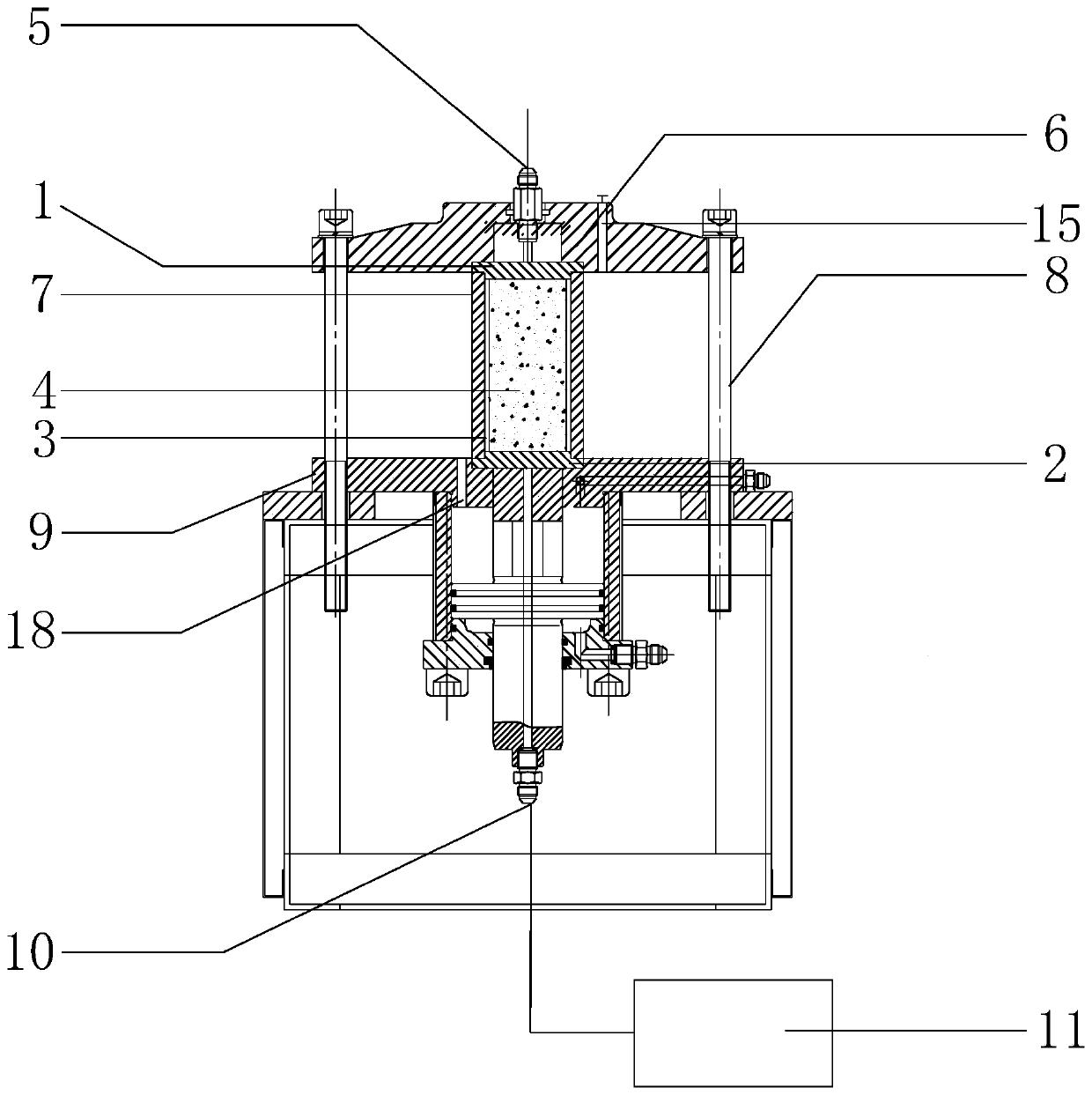

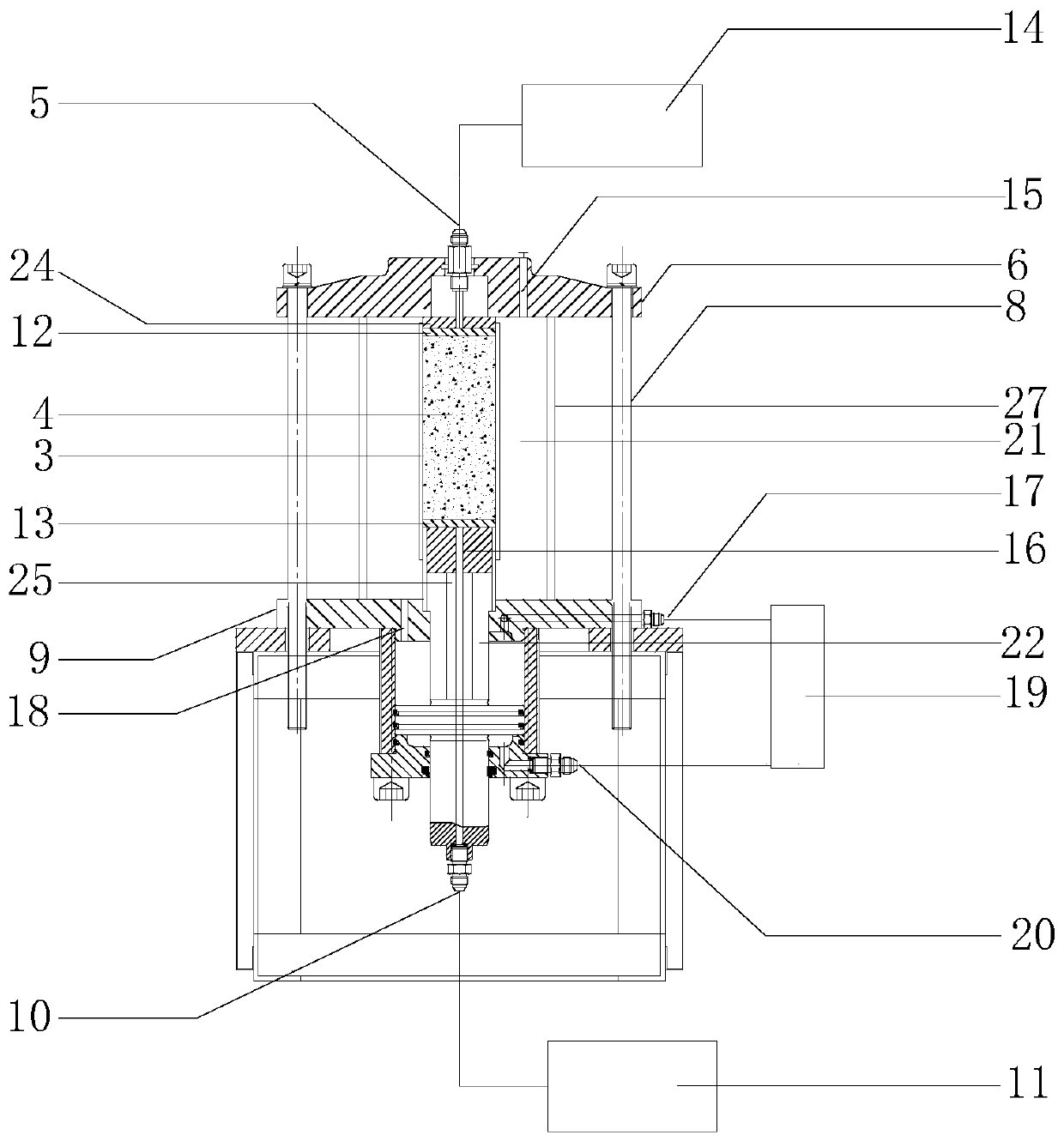

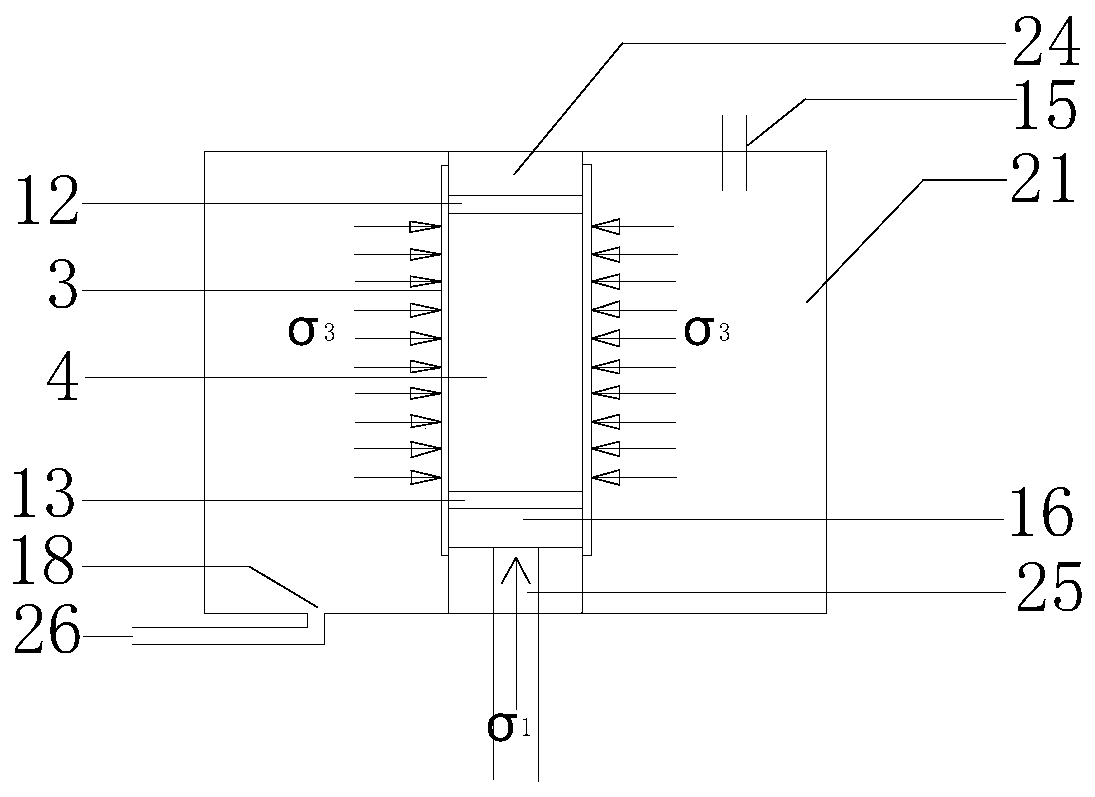

[0028] figure 1 , figure 2 , image 3 Shown is a critical seepage air pressure test device for the face soil of a saturated formation under three-dimensional stress, including a sample saturation unit, a critical seepage air pressure test unit, an axial pressure simulation unit, and a radial confining pressure simulation unit;

[0029] Sample saturation unit: including side wall 7, upper permeable stone 1, lower permeable stone 2, upper cover 6 and base 9, side wall 7 is a bottomless cylinder, and 4 original samples are set with water-proof rubber membrane 3 In the side wall 7, the side wall 7 is closely attached to the water-proof rubber membrane 3, and the upper part and the bottom of the original sample 4 are respectively closely attached to the high-permeability upper permeable stone 1 and the lower permeable stone 2, and finally the lower The permeable stone 2 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com