Titanium concentrate detection method and green pellet detection method

A detection method and technology for ilmenite concentrate, applied in the field of ilmenite concentrate detection and green spheroid detection, can solve the problem of ilmenite concentrate spheroidization performance testing methods and performance indicators that are rarely reported, the practical application guidance is not high, and the guiding role is limited, etc. problems, to achieve the effect of simple and accurate comprehensive evaluation, strong operability, and strong practicality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

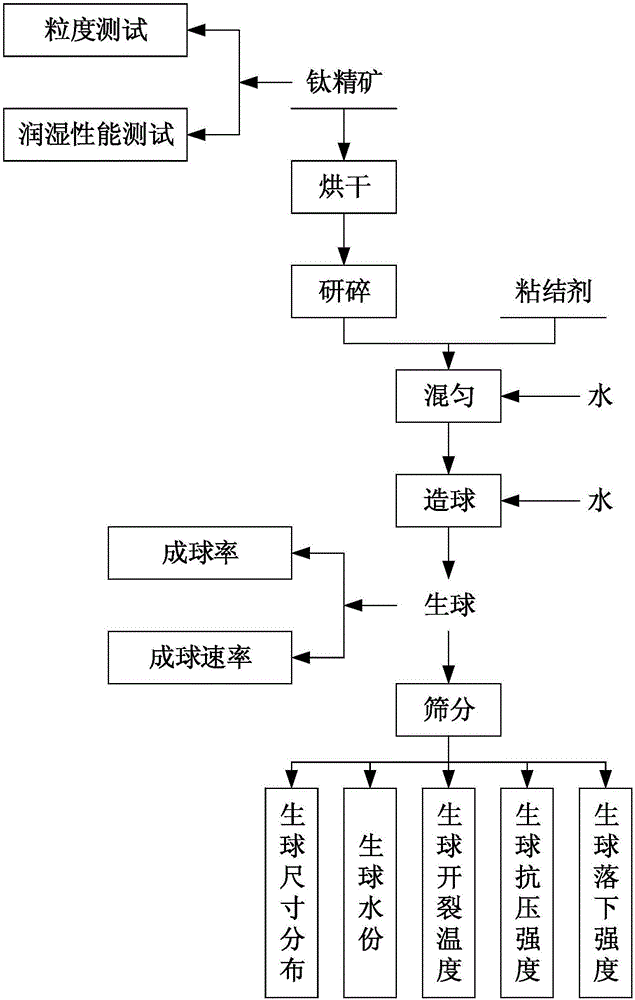

[0024] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0025] The detection method of titanium concentrate comprises the following steps: a. Carry out particle size detection on titanium concentrate: take titanium concentrate, carry out water sieve with 200 mesh, 325 mesh standard sieve, until the water flowing out from the screen is clear, put titanium concentrate After the ore and the screen are placed in an oven for drying, weigh the mass of titanium concentrate on the screen of each particle size, and calculate the percentage of each particle size. Among them, the particle size control range of the material used for pelletizing is: -200 mesh is 70% to 98% %, -325 mesh is 32% to 85%; b. Test the wetting rate of titanium concentrate: add titanium concentrate to the measuring cylinder, then add water to the vector cylinder, observe the volume under water immersion, and measure the volume under water immersi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com