Method for predicting elastic stress and strain of thick-wall cylindrical shell in presence of hydrogen

A prediction method and elastic stress technology, applied in special data processing applications, instruments, electrical and digital data processing, etc., can solve problems such as difficult to generalize, no stress-strain method for hydrogen cylindrical shells, and high quality requirements for researchers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

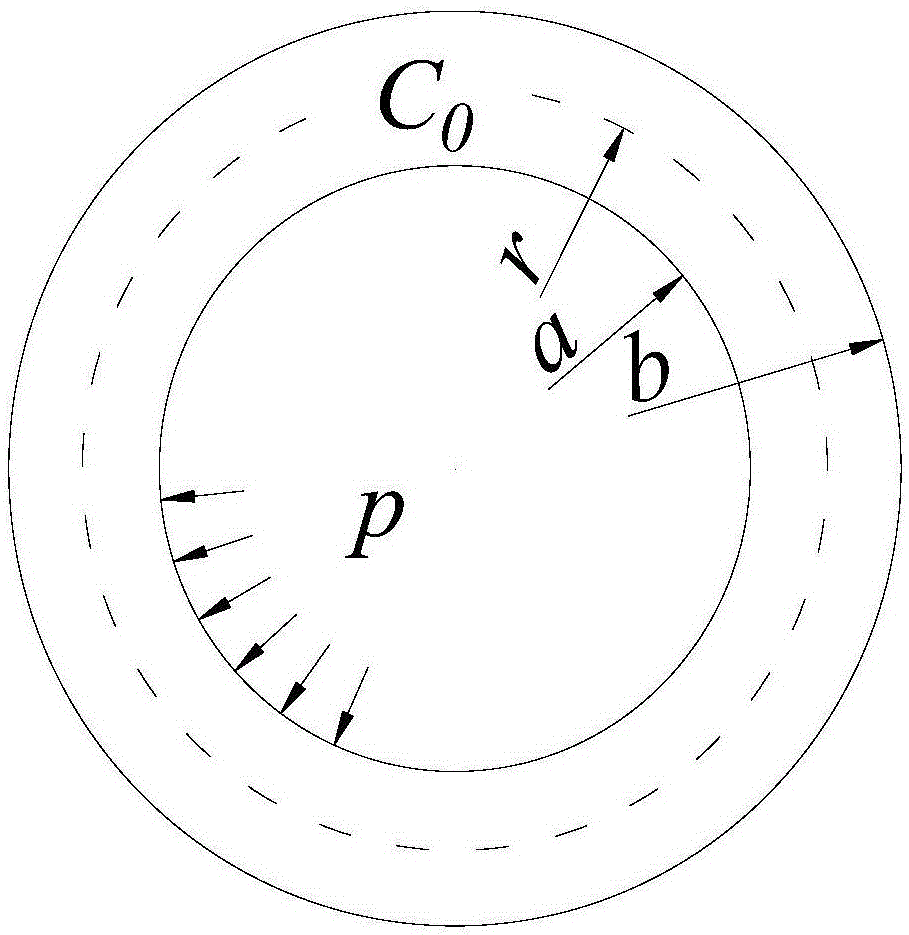

[0042] the following to figure 1 And the example shown in Table 1 is the implementation object, and the present invention is described further.

[0043] figure 1 The example shown is a thick-walled cylindrical shell bound at both ends, with inner and outer radii a and b, respectively, subjected to a constant internal pressure load p, with a concentration c in the unstressed state 0 The hydrogen is uniformly distributed in the cylindrical shell. The invention can predict the stress and strain of the cylindrical shell in the hydrogen environment under the action of internal pressure p.

[0044] Table 1 Material parameters and geometric parameters used in the example

[0045]

[0046]

[0047] The realization process of the inventive method is as follows:

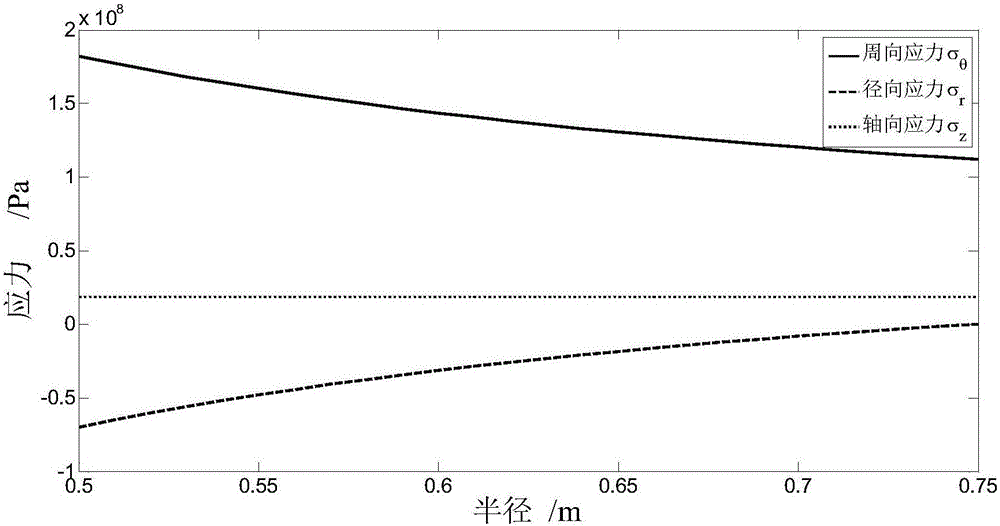

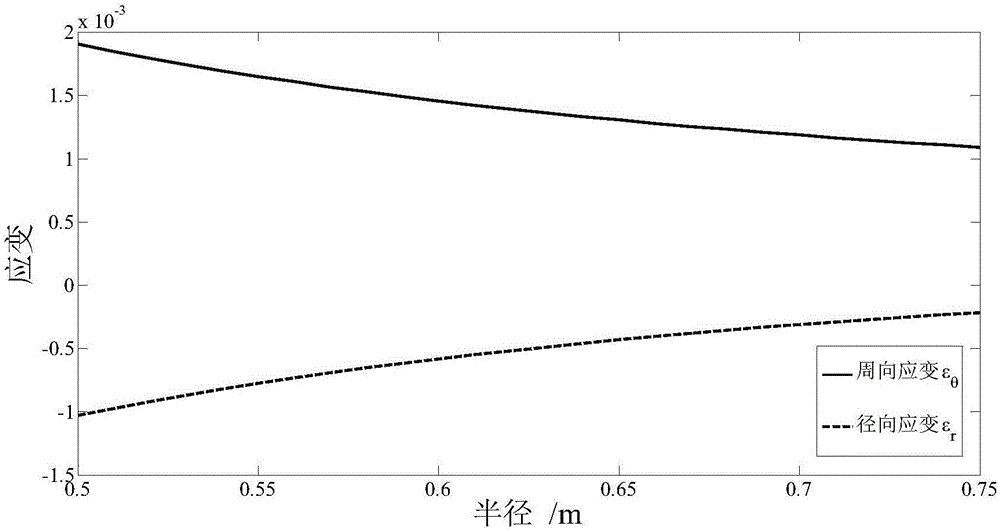

[0048] Step 1: Select a radius r (a≤r≤b), for example, take r=a, and bring the inner radius a, outer radius b and internal pressure load p in Table 1 into the following formula to calculate the circumferential direct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com