Mine gas concentration pre-warning method

A gas concentration, mine technology, applied in special data processing applications, instruments, electrical digital data processing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

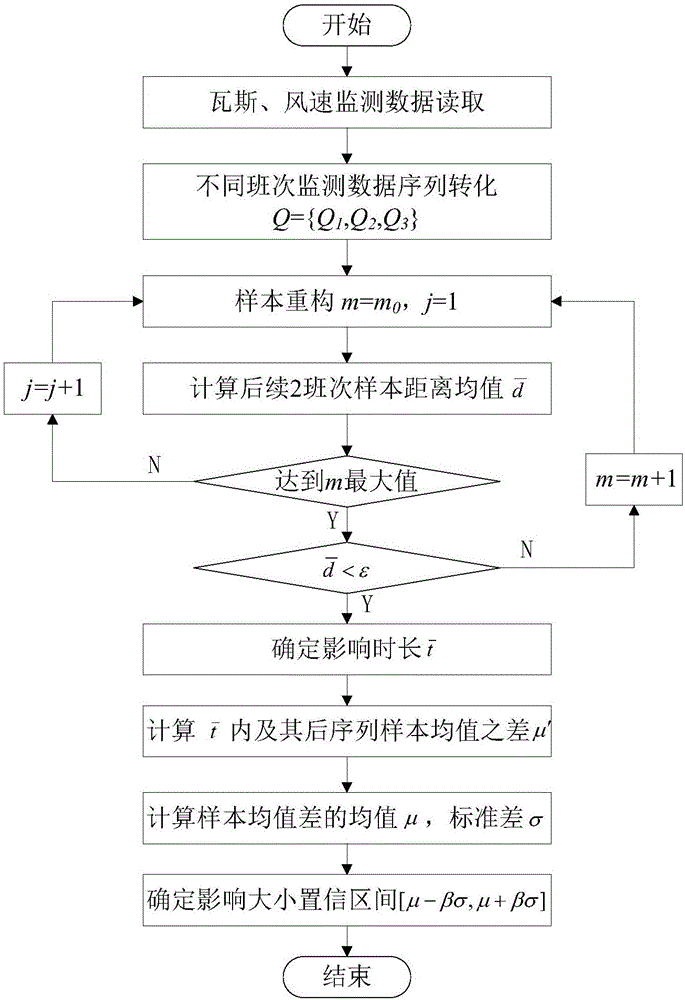

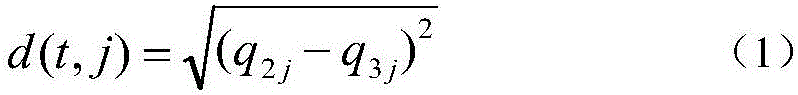

Method used

Image

Examples

Embodiment

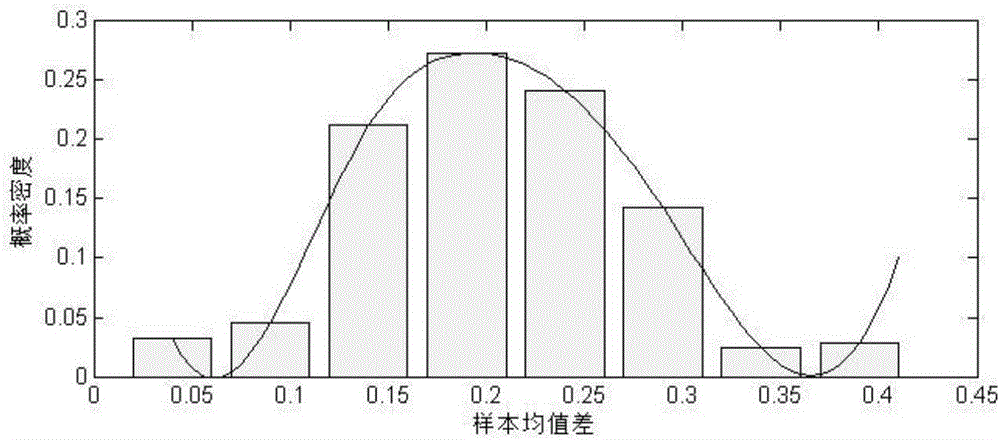

[0048] see figure 2 As shown, the 2015 monitoring data of the mining working face monitoring point of a mine in Shaanxi was selected as historical data to analyze the impact of production on gas emission at the working face. The monitoring period is 30s. Using the above method, set the critical value ε to 0.01. Through repeated calculations, it is found that the sample reconstruction dimension is preferably between 4 and 12, and the probability histogram of the sample mean difference of the gas monitoring data sequence is shown in figure 2 As shown, it is calculated that the production of the working face has an impact on gas emission of 3.2 hours, and the range of gas concentration increment under the influence of production factors is [0.12,0.32]. 0.62m 3 / s, the upper and lower limits of the confidence interval are multiplied by the air volume of the working face respectively to be [0.34,0.90], and the prediction results of different sources are included in the confidenc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com