Filled aerogel ICF cryogenic target system

A technology of filling gas and freezing target, which is applied in the direction of climate sustainability, greenhouse gas reduction, nuclear reactor, etc., to reduce the content, improve the ignition success rate, and optimize the surface temperature uniformity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below in conjunction with the accompanying drawings.

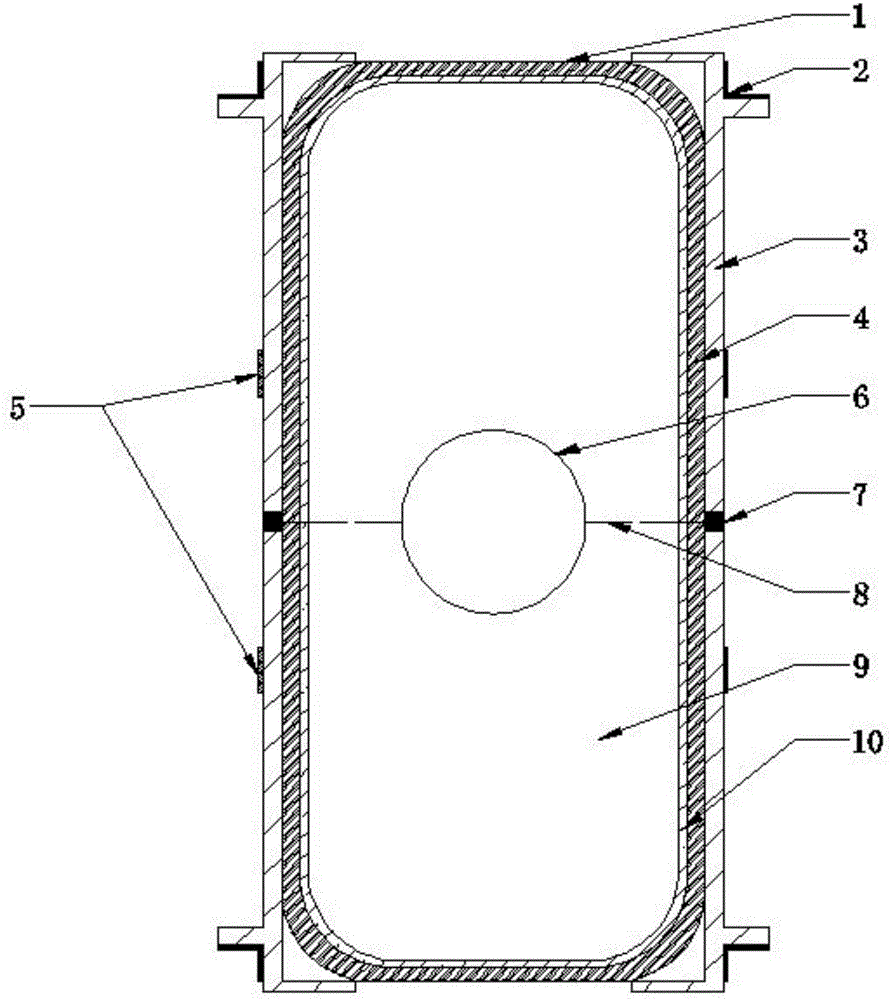

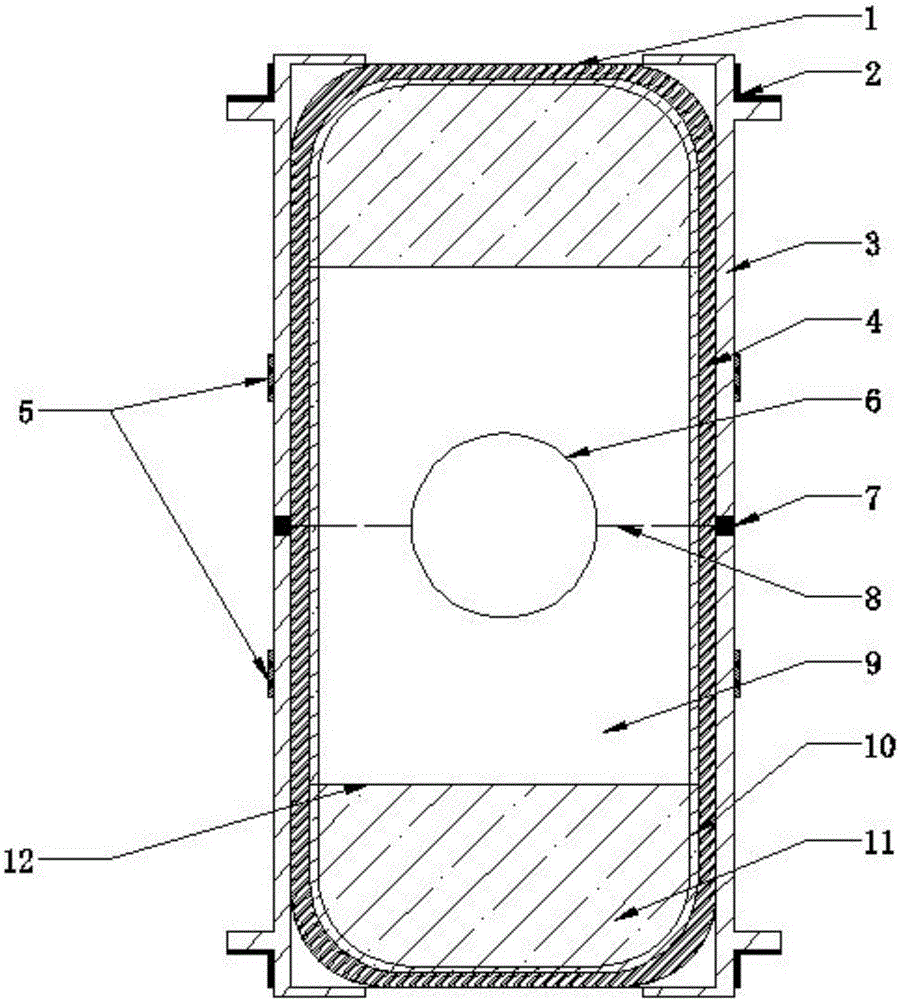

[0017] refer to figure 1 , an airgel-filled ICF freezing target system, comprising a gold chamber 4, a target pellet 6 is fixed in the center of the interior of the gold chamber 4 through a support film 8, fusion materials are contained in the target pellet 6, and a laser incident light is provided on the top of the gold chamber 4 Inlet 1, the laser entrance 1 is the window for the laser to enter when the laser is ignited. The outer part of the golden cavity 4 is provided with a thermomechanical structure 3. The upper and lower parts of the thermomechanical structure 3 are connected into one body through a connecting structure 7. The thermomechanical structure 3 The function is to support the whole system. The thermomechanical structure 3 is provided with a cold ring 2. The cold ring 2 provides cooling capacity for the frozen target structure to achieve the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com