A press-fitting device and a press-fitting method for a semiconductor valve string

A press-fitting device and semiconductor technology, which is applied in the fields of semiconductor devices, semiconductor/solid-state device manufacturing, and semiconductor/solid-state device components, etc., can solve the problems of low standardization of integrated modules, difficult to guarantee assembly accuracy, and impact on accuracy, and avoid The assembly accuracy is destroyed, the press-fitting stability is improved, and the degree of automation is improved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

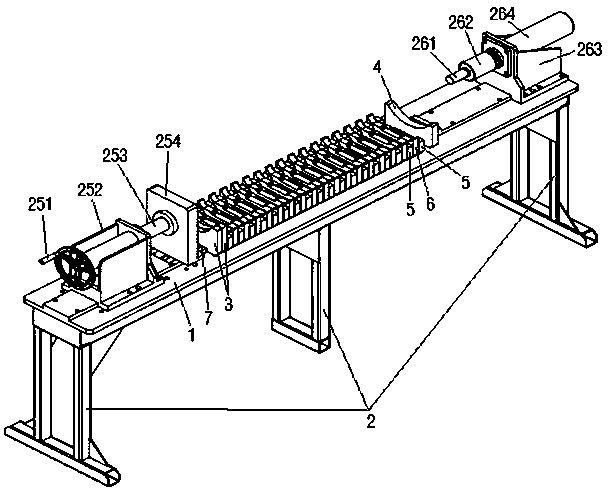

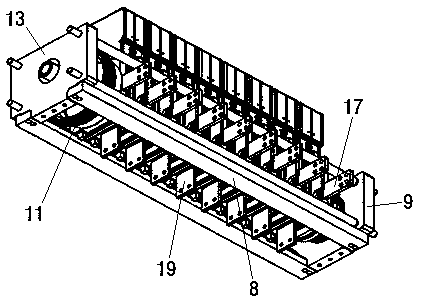

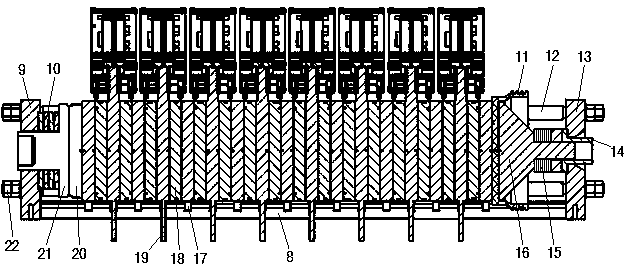

[0030] An example of a press-fitting device for a semiconductor valve string is Figure 1~Figure 9 As shown, it includes a horizontal workbench 1 arranged on the frame 2. The horizontal workbench 1 is provided with a guide support structure for guiding and supporting each device in the semiconductor valve string to be pressed. The guide support structure includes setting The guide rail 7 on the horizontal workbench 1 and the semiconductor support seat 6 used to position and support the semiconductor are guided and slidably assembled on the guide rail 7. In this embodiment, the semiconductor is an IGBT18, and the semiconductor valve string It is an IGBT valve string, and the semiconductor support seat 6 has a semiconductor support surface matching the shape of the bottom of the IGBT 18 . The guide rail 7 is also guided and slidably equipped with the radiator support seat 5 for supporting the corresponding radiator in the semiconductor valve string, and the radiator includes the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com