Method for manufacturing all-solid battery

A technology of all-solid-state battery and manufacturing method, applied in secondary battery manufacturing, electrolyte storage battery manufacturing, battery and other directions, can solve problems such as short circuit, and achieve the effect of suppressing the decrease of internal resistance value and suppressing short circuit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

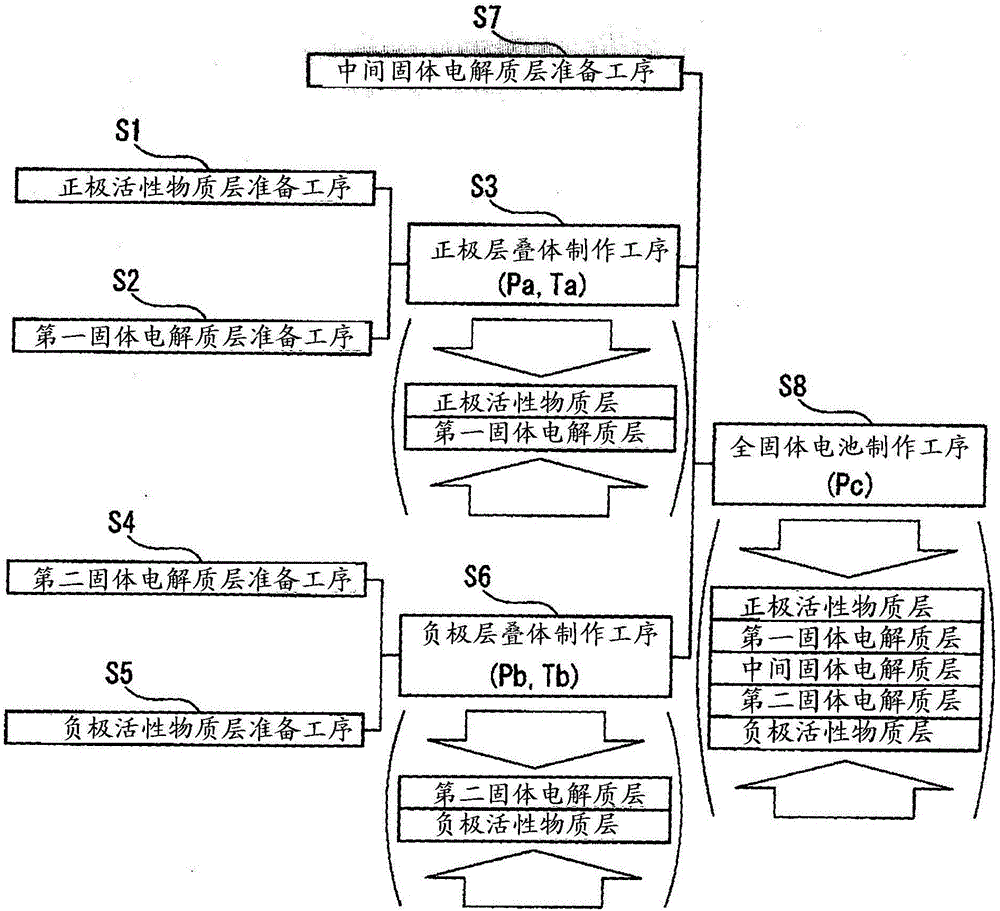

Method used

Image

Examples

Embodiment 1

[0178] (Positive electrode active material layer preparation process)

[0179]A positive electrode mixture, which is a raw material of the positive electrode active material layer, was placed in a container made of polypropylene (PP). It was continuously stirred for a total of 150 seconds with an ultrasonic dispersion device (manufactured by Esuemte Corporation, model: UH-50), and was continuously shaken for a total of 20 minutes with a vibrator (manufactured by Shibata Science Co., Ltd., model: TTM-1), thereby preparing Positive electrode active material slurry.

[0180] Using an applicator, the positive electrode active material slurry was applied on an Al foil serving as a positive electrode current collector layer by a doctor blade method. Drying was continued on a hot plate at 100° C. for 30 minutes to obtain a positive electrode active material layer formed on an Al foil serving as a positive electrode current collector layer.

[0181] To illustrate, the composition of...

Embodiment 2

[0220] An all-solid battery of Example 2 was fabricated in the same manner as in Example 1 except that the pressing pressure in the third pressing step was set to 100 MPa.

Embodiment 3~5 and comparative example 2~6

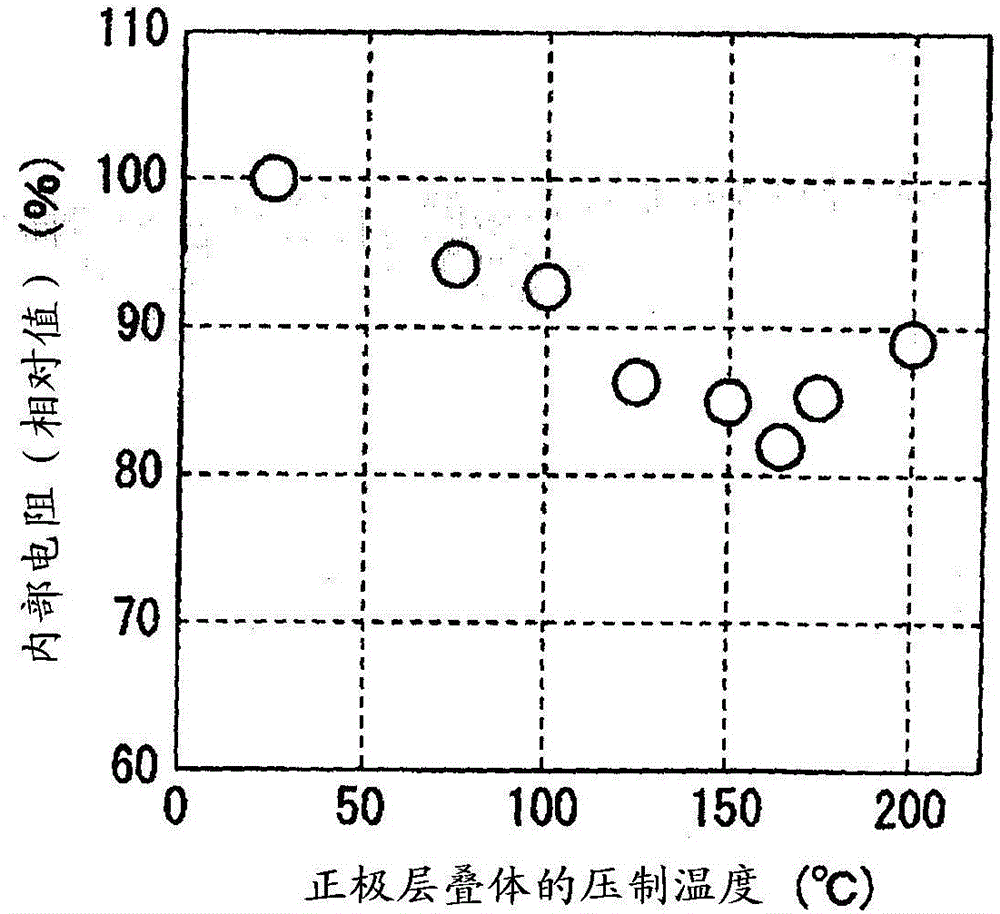

[0236] Except that the pressing temperature in the first pressing step was changed as shown in Table 2 below, the production conditions were the same as those of the all-solid-state battery of Example 1 to produce all solid-state batteries of Examples 3-5 and Comparative Examples 2-6. solid battery.

[0237] "evaluate"

[0238] The internal resistance values of the all solid state batteries of Examples 3 to 5 and Comparative Examples 2 to 6 were evaluated. The results are shown in Table 2 and figure 2 .

[0239] [Table 2]

[0240]

[0241] In addition, please refer to the description in Table 1 for the measurement method of the internal resistance value of the all-solid-state battery.

[0242] figure 2 The relationship between the pressing temperature (°C) of the positive electrode laminate and the internal resistance value (relative value) (%) of the all solid battery is shown for an all solid battery in which a positive electrode laminate, an intermediate solid e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com