IGBT-based hybrid high-voltage direct-current circuit breaker

A high-voltage DC and circuit breaker technology, applied in emergency protection circuit devices, electrical components, etc., can solve the problems of increasing the difficulty of IGBT series voltage equalization, solid-state switch damage, and turn-off failures, saving the number of IGBTs in series and reducing the number of series. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

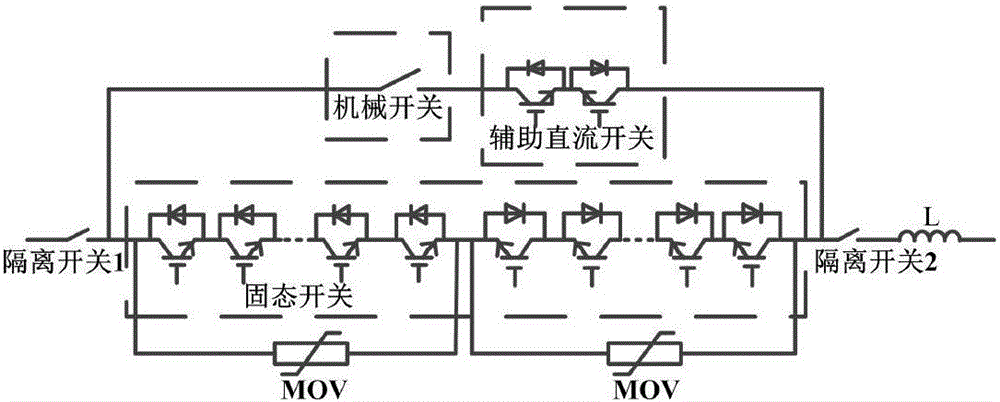

[0027] I topology

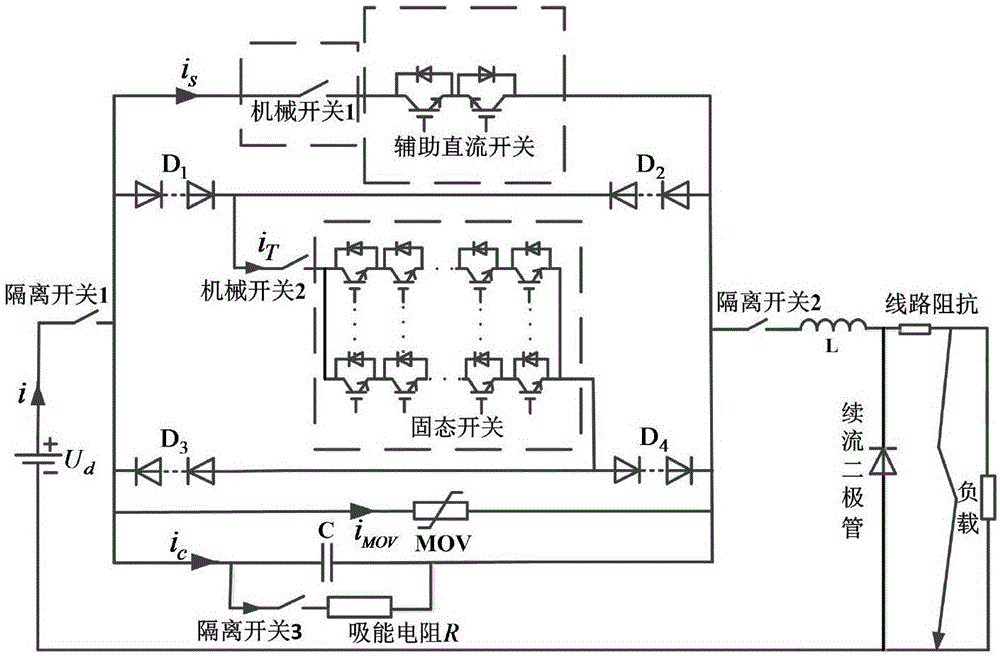

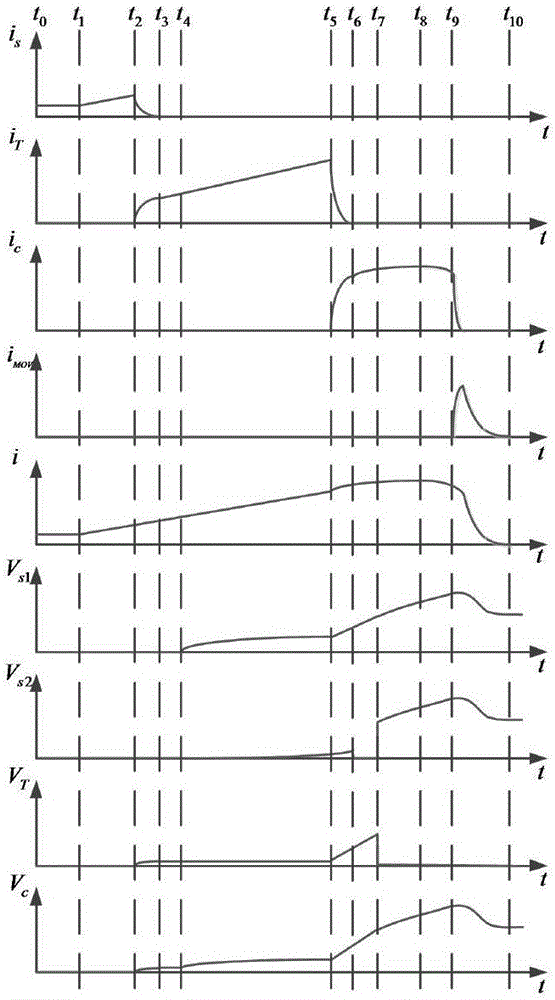

[0028] In order to solve the defects of the hybrid high-voltage DC circuit breaker developed by ABB, the present invention proposes a new type of hybrid high-voltage DC circuit breaker, whose topology is shown in the attached figure 2 As shown, its characteristics are as follows.

[0029] ① In the commutation branch, the diode valve bridge structure D 1 and D 4 Realize bidirectional turn-on and turn-off. Definition attached figure 2 The i direction is the forward direction of the current. When the current flows forward, the current of the commutation branch passes through D 1 → Mechanical Switch 2 → Solid State Switch → D 4 flow through; when the current flows in reverse, the commutation branch current passes through D 2 → Mechanical Switch 2 → Solid State Switch → D 3 flow past. Since a group of IGBTs can flow current in both forward and reverse directions, compared with ABB circuit breakers, half of the IGBTs are saved.

[0030] ② A mechanical ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com