A charging system and method

A technology of a charging system and a charging method, which is applied in the direction of current collectors, electric vehicles, electrical components, etc., can solve problems such as limiting fast charging capabilities, heating of mobile devices, and large pressure differences, so as to avoid cable and connector compatibility, High voltage, low current, high efficiency and fast, avoiding severe heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

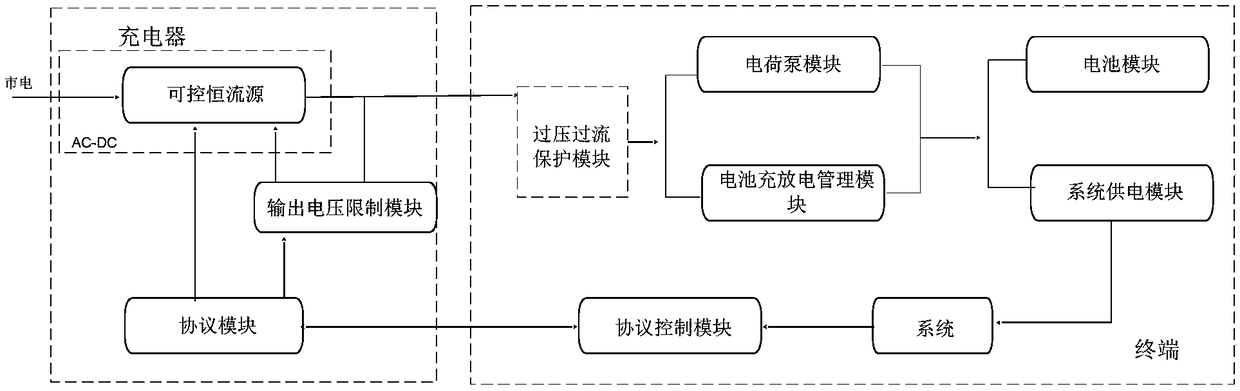

[0076] Such as figure 2 As shown in the schematic structural diagram of the charging system of the present invention, in addition to the modules, functions and connection relationships that have been described above, the terminal side also includes an overvoltage and overcurrent protection module, and the overvoltage and overcurrent protection module is located in the charging system. Between the device and the charge pump module of the terminal, the overvoltage and overcurrent protection module is an external module located in the terminal. The battery charging and discharging management module includes an overvoltage and overcurrent protection module, which is used to detect the voltage and current delivered to the terminal by the charger and provide an overvoltage and overcurrent shutdown protection function, and limit the input current to a safe zone. The path management module is used to dynamically allocate the charging current path according to the charging state of t...

Embodiment 2

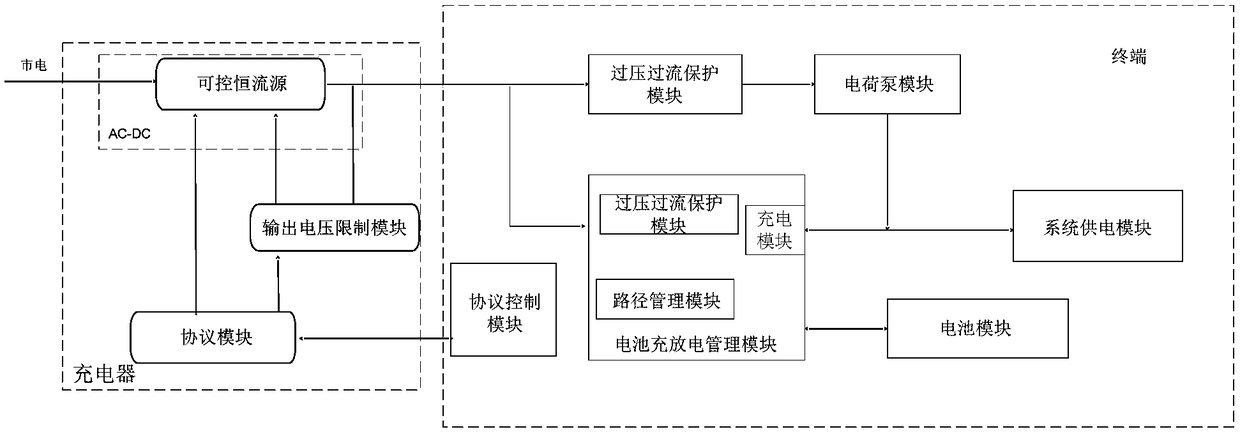

[0080] Such as image 3 As shown, it is a schematic structural diagram of another battery charging system of the present invention, and the same parts as those in Embodiment 1 will not be repeated here. The difference between this embodiment and Embodiment 1 is that instead of using an external overvoltage and overcurrent protection module, the overvoltage and overcurrent protection module in the battery charge and discharge management module is directly used to perform overvoltage and overcurrent protection. Protect. Specifically, the charger is electrically connected to the overvoltage and overcurrent protection module in the battery charge and discharge management module, and the output terminal of the overvoltage and overcurrent protection module is electrically connected to the input terminal of the charge pump module , the output end of the charge pump module is electrically connected to the battery charge and discharge management module and the system power supply modu...

Embodiment 3

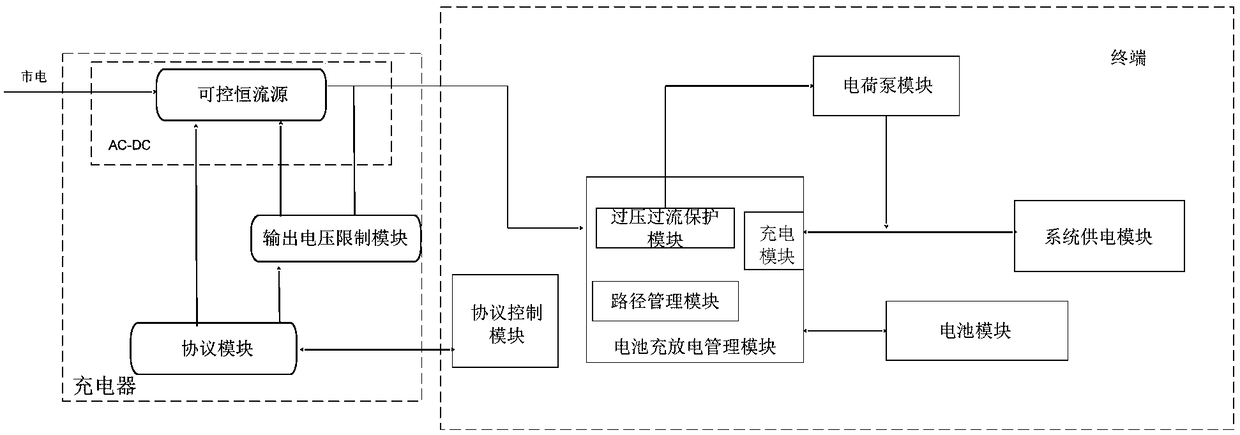

[0083] Such as Figure 4As shown, a schematic structural diagram of another battery charging system of the present invention is the same as the first half of the structure of the charging system described in Embodiment 1, and will not be repeated here. The difference is also obvious. In this embodiment, the system power supply module is connected in series to the rear side of the battery charge and discharge management module, so the path management module in the battery charge and discharge management module is not needed in the constant current charging stage. function, but the pre-charging and constant voltage charging stages still need path management. Here, it should be noted that the component modules in the drawings of the present invention are mainly based on the component modules required for constant current charging, so all components of the battery charge and discharge management module are omitted in the drawings of this embodiment. The above path management modu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com