Nitrogen-phosphorus synergetic copolymerization flame retardant polylactic acid fibers and preparation method thereof

A polylactic acid fiber, copolymerized flame-retardant technology, applied in the field of preparation of phosphorus-nitrogen synergistic copolymerized flame-retardant polylactic acid fiber, can solve the problems of poor mechanical properties of fibers, PLA easy to burn, poor compatibility, etc., and achieve excellent flame retardancy Performance and mechanical properties, short preparation process, and broad market prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

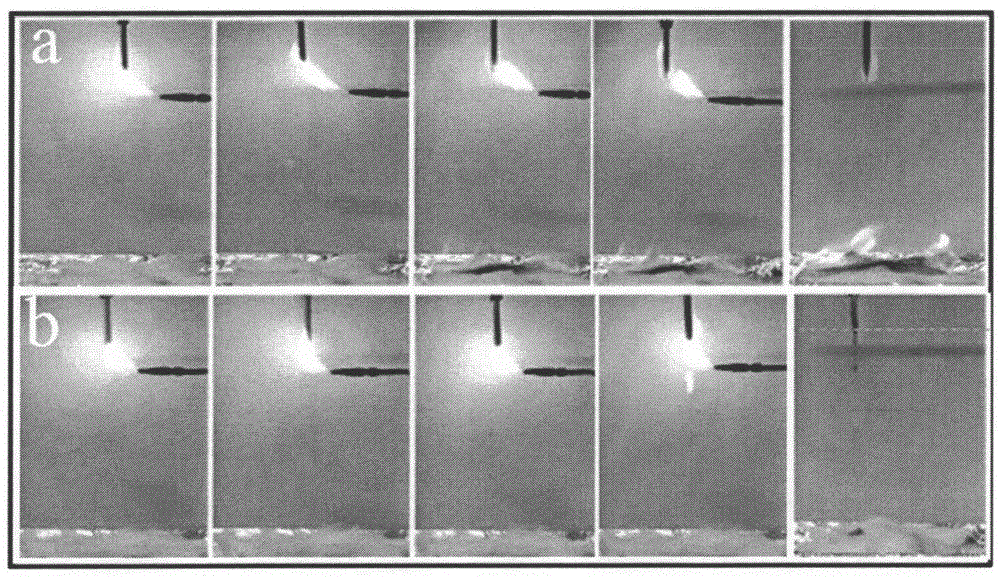

Image

Examples

Embodiment 1

[0028] A preparation method of nitrogen-phosphorus synergistic copolymerization flame-retardant polylactic acid fiber, the specific steps are:

[0029] (1) Preparation of nitrogen-phosphorus synergistic flame retardant monomer (FR): with N 2 As protective gas, dissolve 0.1mol aminophenol (DDS) and 0.1mol p-hydroxybenzaldehyde (HBH) in 100ml solvent methanol, heat up to 40°C, and react for 4 hours to obtain the intermediate without separation and purification; 2 As a protective gas, take 0.1mol intermediate and 0.2mol 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide (DOPO) and dissolve in 200ml tetrahydrofuran (THF), heat up to 40°C, After 10 hours of reaction, nitrogen-phosphorus synergistic flame retardant monomer (FR) can be obtained without separation and purification.

[0030] (2) Dry LA and FR at 80°C for 24 hours to remove moisture; dry the reaction vessel at 100°C for 1 hour to remove moisture, and continuously pass inert gas N 2 replace the air;

[0031] (3) FR an...

Embodiment 2

[0035] A preparation method of nitrogen-phosphorus synergistic copolymerization flame-retardant polylactic acid fiber, the specific steps are:

[0036] (1) Preparation of nitrogen-phosphorus synergistic flame retardant monomer (FR): with N 2 As a protective gas, dissolve 0.4mol aminophenol (DDS) and 0.4mol p-hydroxybenzaldehyde (HBH) in 300ml solvent methanol, heat up to 80°C, and react for 8 hours to obtain the intermediate without separation and purification; 2 As a protective gas, take 0.4mol of intermediates and 0.8mol of 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide (DOPO) and dissolve it in 800ml of tetrahydrofuran (THF), and heat up to 80°C , after 16 hours of reaction, the nitrogen-phosphorus synergistic flame retardant monomer (FR) can be obtained without separation and purification.

[0037] (2) Dry LA and FR at 80°C for 24 hours to remove moisture; dry the reaction vessel at 100°C for 1 hour to remove moisture, and continuously pass inert gas N 2 replace the ...

Embodiment 3

[0042] A preparation method of nitrogen-phosphorus synergistic copolymerization flame-retardant polylactic acid fiber, the specific steps are:

[0043] (1) Preparation of nitrogen-phosphorus synergistic flame retardant monomer (FR): with N 2 As a protective gas, dissolve 0.2mol aminophenol (DDS) and 0.2mol p-hydroxybenzaldehyde (HBH) in 200ml solvent methanol, heat up to 60°C, and react for 6 hours to obtain the intermediate without separation and purification; 2 As a protective gas, take 0.2mol of intermediate and 0.4mol of 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide (DOPO) and dissolve it in 500ml of tetrahydrofuran (THF), and heat up to 60°C , after 12 hours of reaction, the nitrogen-phosphorus synergistic flame retardant monomer FR can be obtained without separation and purification.

[0044] (2) Dry LA and FR at 80°C for 24 hours to remove moisture; dry the reaction vessel at 100°C for 1 hour to remove moisture, and continuously pass inert gas N 2 replace the air...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com