Speed regulation method for direct current brushless motor

A brushless DC motor, speed adjustment technology, applied in the direction of speed/torque control of a single motor, can solve the problems of constant power speed regulation, difficulty, size change, etc., achieve effective electromagnetic energy, overcome constant torque speed regulation , Improve work efficiency and performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

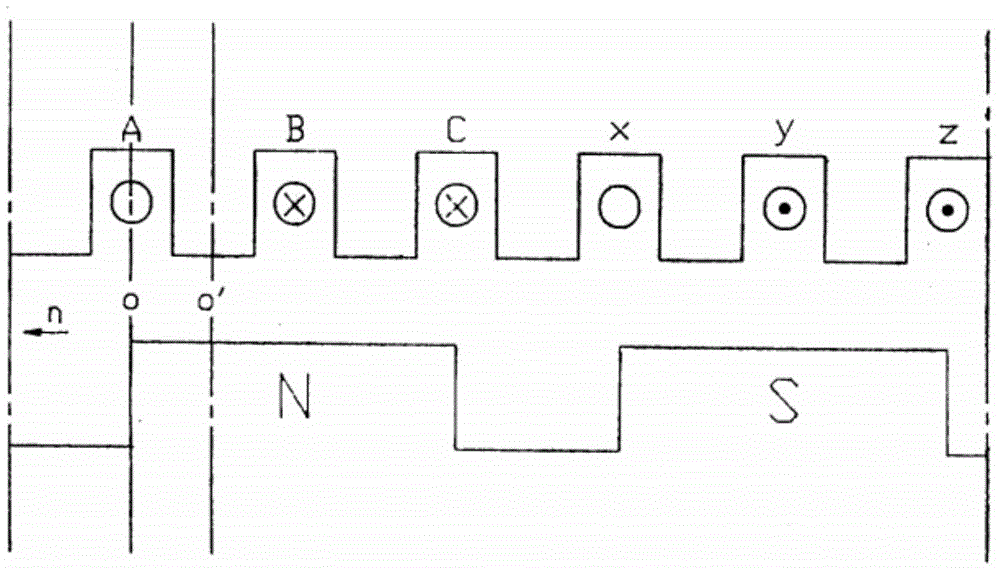

[0011] The present invention is described in detail by taking a two-pole three-phase DC brushless motor as an example.

[0012] The potential balance equation of each phase winding of the motor is:

[0013] u=e+iR

[0014] Among them, i is the current of each phase winding, R is the resistance of each phase winding, and iR is the resistance voltage drop of each phase winding. This value is relatively small when the motor is in normal operation, u is the applied voltage; e is each phase winding The back electromotive force can be expressed by the following formula:

[0015] e=L(di / dt)+NBlv

[0016] Among them, L is the inductance of each phase winding, L(di / dt) is the "inductance potential" generated by each phase winding due to current changes; N is the total number of wires in each phase winding, B is the air gap flux density, and the magnetic field is composed of permanent The magnet is generated, l is the length of the wire, v is the relative motion speed of the wire (eq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com