Raw material hot boiling mechanism of solid polyphenol production line

A production line and polyphenol technology, which is applied in the field of solid polyphenol production equipment, can solve the problems that raw materials cannot be heated to the ideal state, the heating speed is slow, and the heating is not uniform enough.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

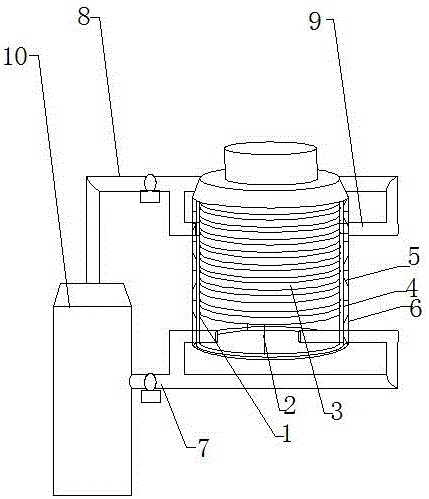

[0014] Such as figure 1 As shown, the raw material boiling mechanism on the solid polyphenol production line of the present invention includes a stainless steel drum 1, and a support seat 2 arranged at the bottom of the stainless steel drum, and a corrugated heat-absorbing layer 3 that presses the periphery of the stainless steel drum; and is arranged on a stainless steel drum. The auxiliary heat absorption layer 4 on the outside of the drum and the support seat; the heat insulation layer 5 arranged on the periphery of the auxiliary heat absorption layer, and the protective layer 6 arranged on the periphery of the heat insulation layer; and the steam passing through the protective layer to the support seat The heating pipe 7 and the steam heat exchange pipe 8 penetrating through the protective layer to the upper peripheral part of the stainless steel drum; the steam heating pipe 7 and the steam heat exchange pipe 8 are connected to the steam heating device 9 .

[0015] The st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com