Sandstone grinding and screening plant for construction engineering

A screening device and construction engineering technology, applied in the fields of filtration, solid separation, chemical instruments and methods, etc., can solve the problems of no design, low work efficiency, and inability to grind sand and gravel, etc., to achieve enhanced filtering effect, ingenious structure, well-designed effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

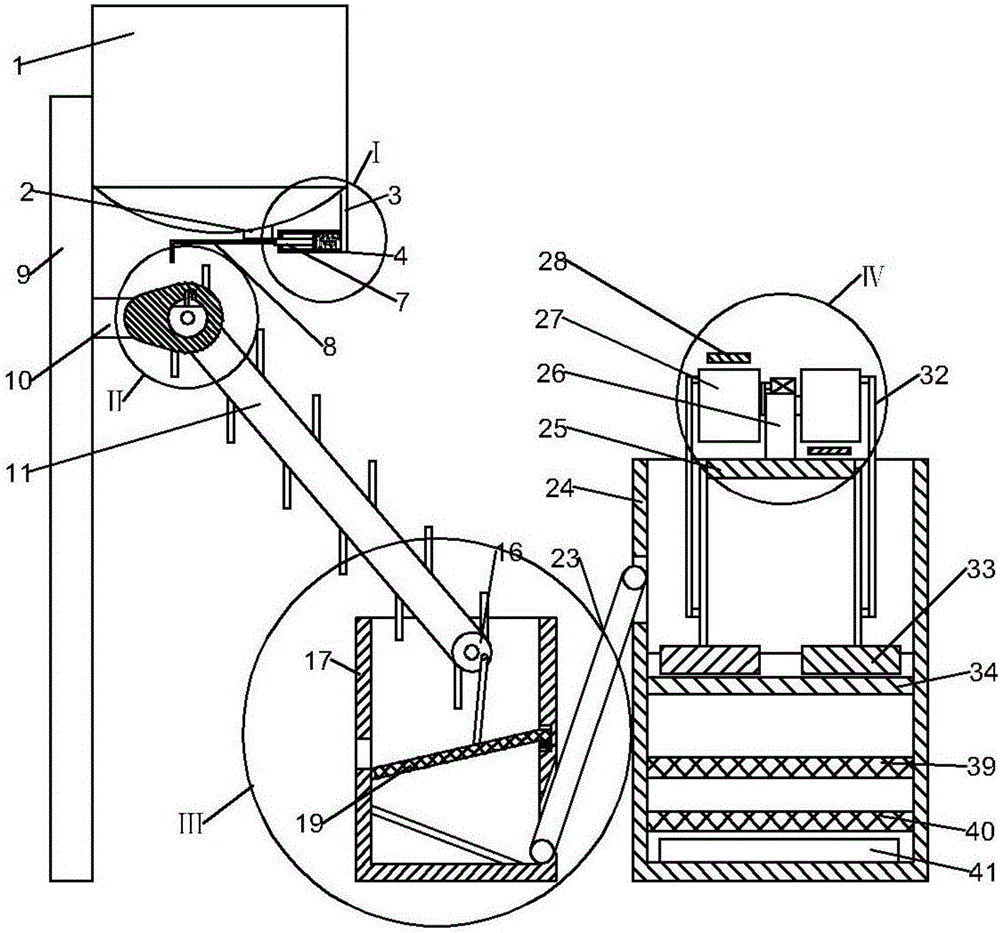

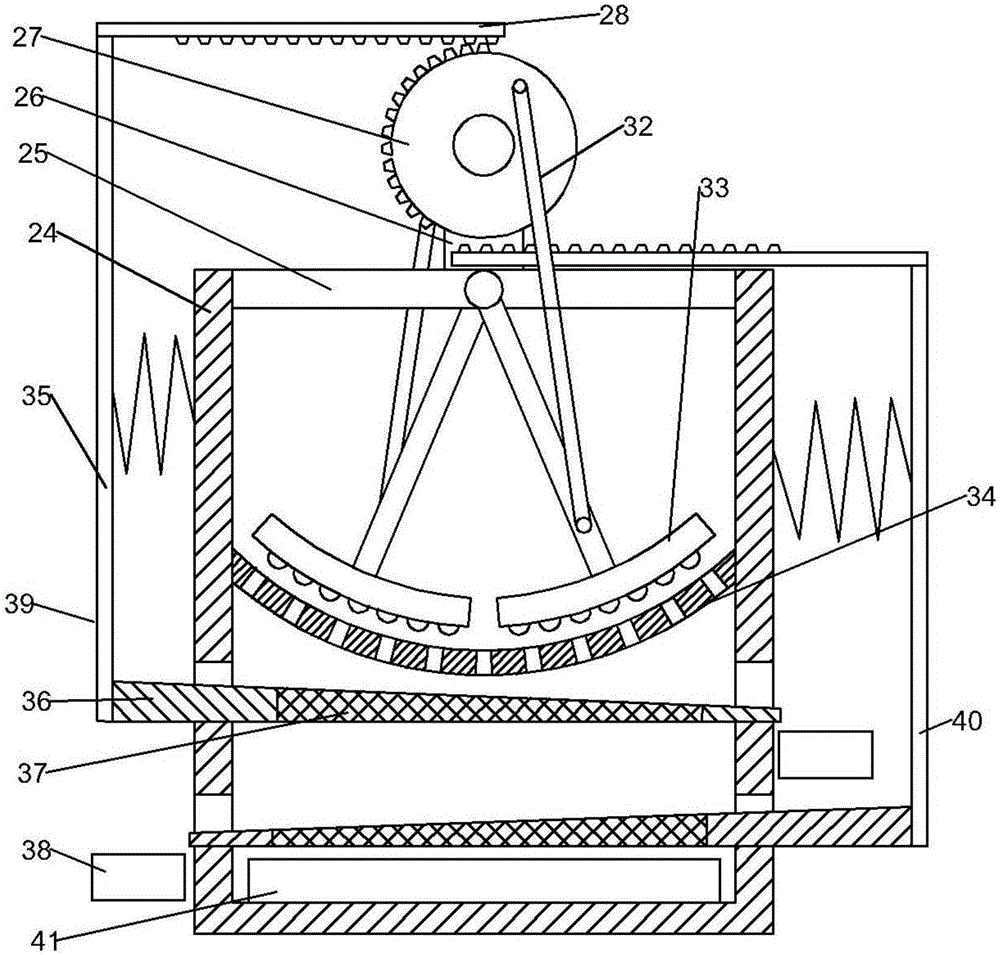

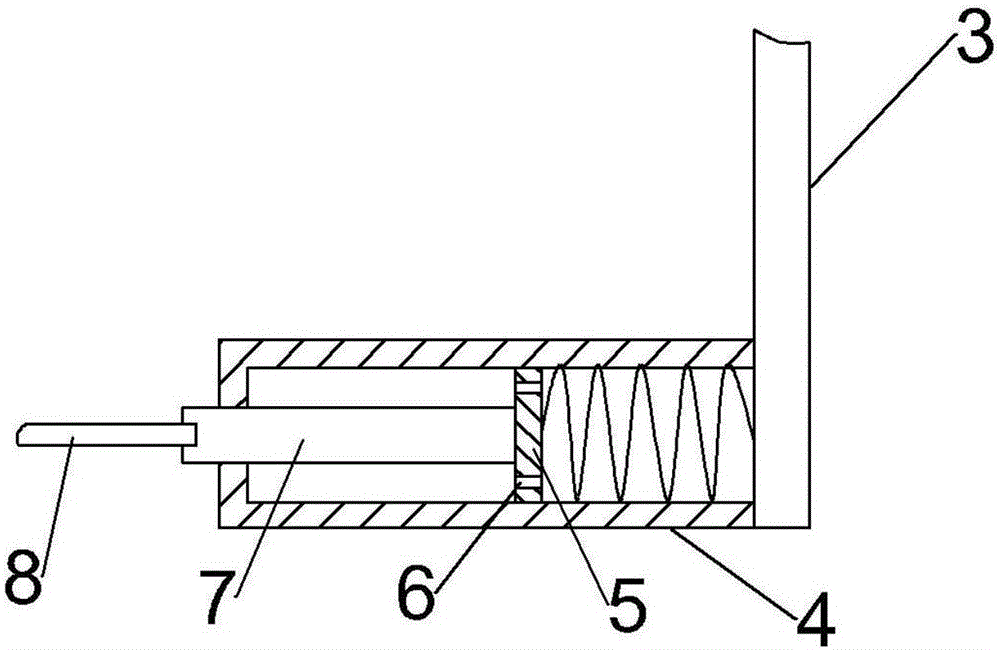

[0024] see Figure 1-6 , a sandstone grinding and screening device for construction engineering, comprising an automatic raw material conveying device, a filtering device and a grinding and screening device, the bottom of the automatic raw material conveying device is provided with a filtering device, and the filtering device includes a housing 17, The right side of the filter device is provided with a grinding and screening device, the grinding and screening device includes a casing 24, a lifting conveyor belt 23 is provided between the casing 17 and the casing 24, and the lifting conveyor belt 23 passes through the casing 17 The bottom of the right side wall body and the top of the left side wall body of casing 24, the inner upper side of casing 24 is provided with support plate 25, and the front end and rear end of described support plate 25 are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com