Welding method for filter screen

A welding method and filter technology, applied in welding equipment, welding/welding/cutting items, non-electric welding equipment, etc., can solve problems such as low strength of solder joints at joints, influence on hydraulic mechanism transmission, and shortened service life. Achieve the effect of avoiding color difference in appearance, no desoldering service life, and stable use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

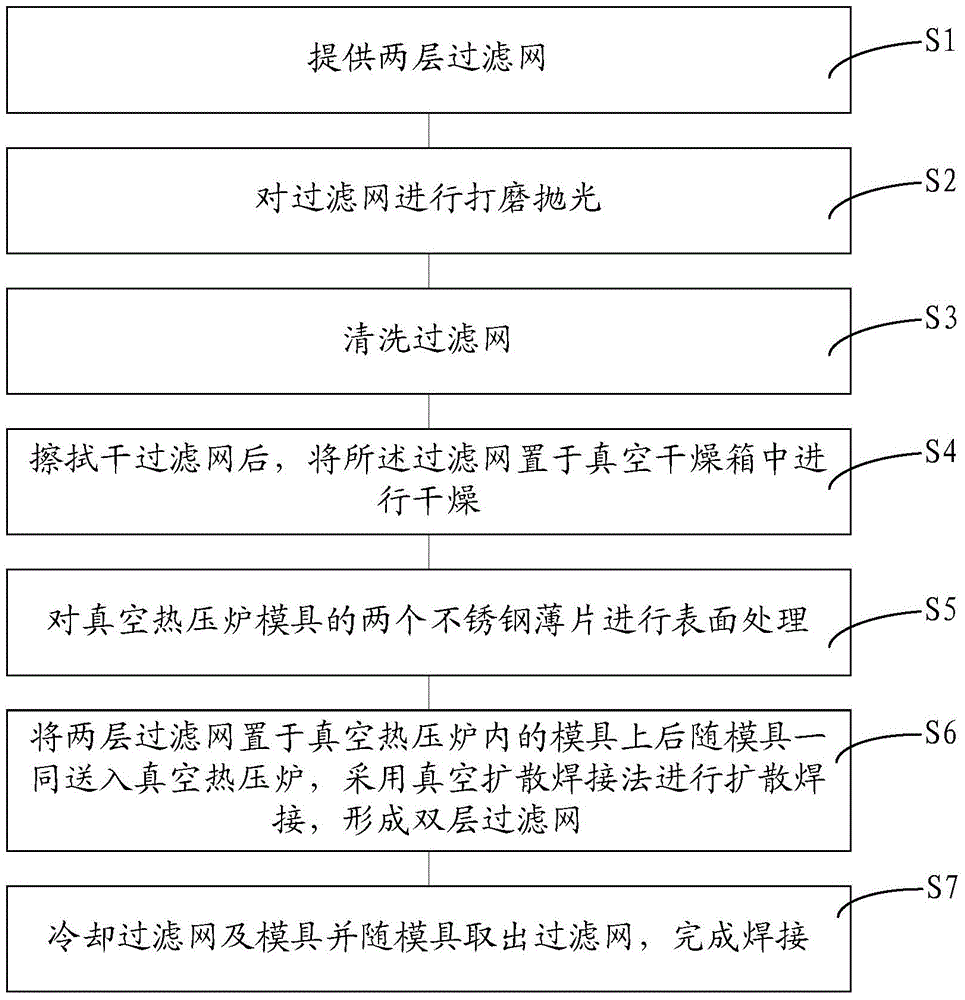

[0033] After the inventor's analysis, it is found that the prior art filter screen is welded by argon arc welding, and multi-point welding is performed on the contact surface of the double-layer filter screen. In the use process of the double-layer filter screen made by this method, the welding joint strength of the joint is not high, and the double-layer filter screen is easy to fall off, which affects the transmission of the hydraulic mechanism.

[0034] In order to solve the problem of low welding joint strength when the double-layer filter screen is made by the argon arc welding method, the inventor of the present invention has further studied the welding method and found that the multi-point welding of the edge contact surface in the prior art is optimized to The face-to-face welding of the stainless steel filter screen realizes the large-area welding between the filter screens, so that the double-layer filter screens mutually diffuse to form a tight bonding layer. The filter...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mesh | aaaaa | aaaaa |

| Mesh | aaaaa | aaaaa |

| Mesh | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com