Multifunctional ceramic tile and manufacturing method thereof

A manufacturing method and multi-functional technology, applied in the field of ceramic tiles, can solve the problems of no derivative function, shortened time for receiving sunlight, public health impact, etc., and achieve the effect of improving sub-health conditions and uniform heat distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

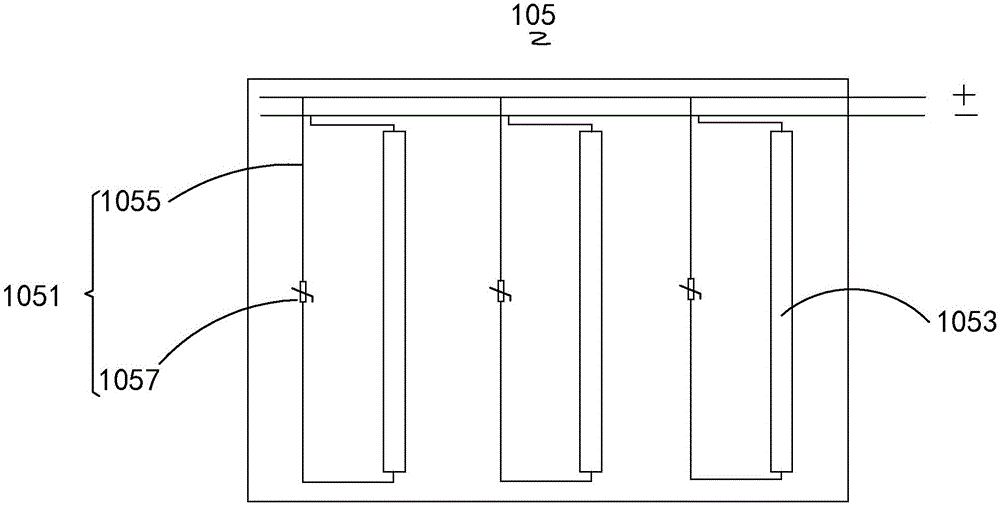

[0061] see Figure 8 , the present invention also provides the first embodiment of the multifunctional ceramic tile manufacturing method, the method includes the following steps:

[0062] S1: Mix ceramic adobe and far-infrared ceramic powder according to the prefabricated ratio, and fire to form a ceramic substrate for later use.

[0063] The far-infrared porcelain powder accounts for 5% to 10% of the total weight of the ceramic adobe and the far-infrared porcelain powder. After being uniformly mixed according to the above weight ratio, it is put into a pre-prepared ceramic formwork and fired at a temperature of 1250°C to 1350°C. system, preferably firing at 1300°C to prepare a ceramic substrate.

[0064] S2: Making a pattern.

[0065] The pattern corresponds to the pattern shape of the heating part 1053. Taking the first embodiment as an example, the shape of the heating part 1053 is a strip shape, and the corresponding pattern shape is made into a strip shape. The pattern ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electron mobility | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com