Molding tool for composite of closed angle structure

A composite material and forming tooling technology, applied in the field of composite material manufacturing, can solve the problems of design combination, complex positioning, split mold matching gap, metal mold weight, etc., to reduce the difficulty of mold manufacturing, solve the separation surface level difference, solve Effects of demolding problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

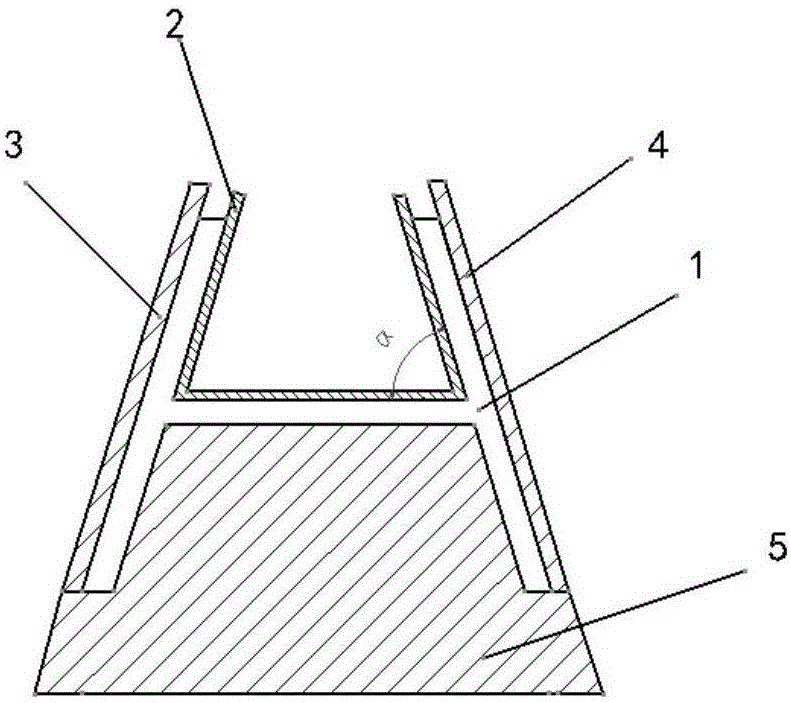

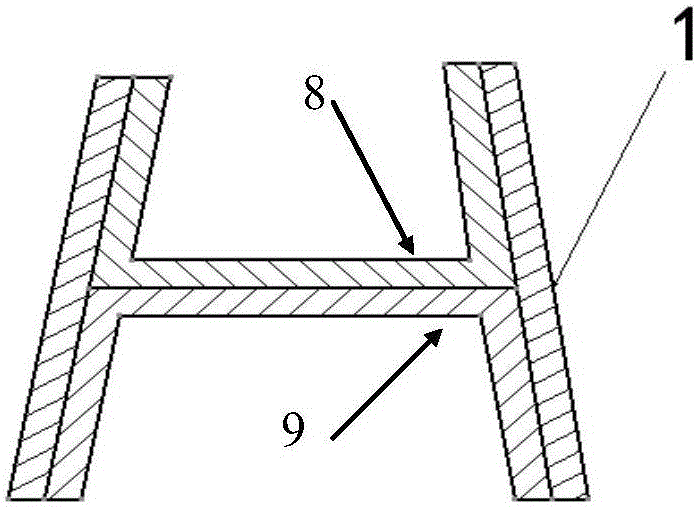

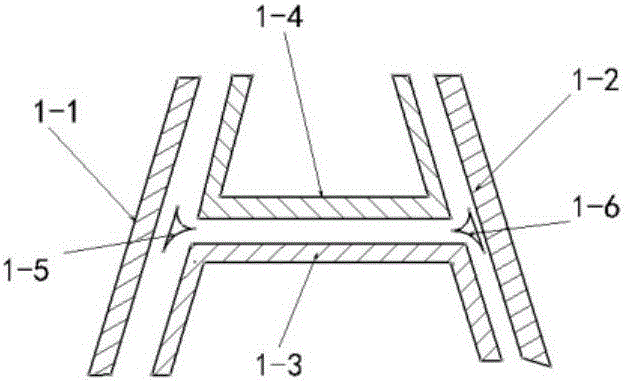

[0017] The present invention will be described in detail below in conjunction with the accompanying drawings. Composite material forming tooling includes lower die 5, upper die 7, and composite material forming tooling also includes left and right edge strip surface cover plates 3 and 4, semi-rigid pressure pad 2; The web profile 9 of the open corner part of the composite material part is consistent, the lower hard mold 5 is used as the layup mold for the layup group 1-3 of the web area of the open corner part of the composite material part, and the semi-rigid pressure pad 2 is pre-impregnated with glass cloth The materials are stacked and solidified, and the outer surface of the semi-rigid pressure pad 2 is consistent with the web surface 8 of the closed corner part of the composite material part. The semi-rigid pressure pad 2 is placed on the upper hard mold 7, and the semi-rigid pressure pad 2 After being combined with the upper hard mold 7, it is used as the layup mold f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com