A method for improving the overall performance of a rail vehicle bogie and a suspension damping system

A rail vehicle and bogie technology is applied in the field of improving the overall performance of the rail vehicle secondary suspension bogie, and can solve the problems of axle box bearing wear and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

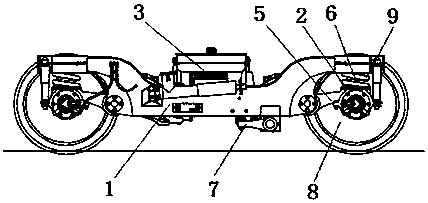

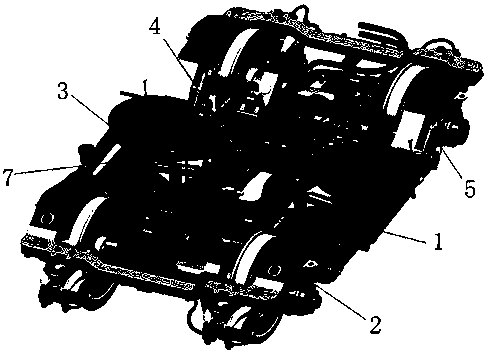

[0069] attached figure 1 and 2 A specific embodiment of the present invention is provided; a bogie suspension vibration damping system includes a primary suspension system 2, a secondary suspension system 3 and a drawbar system 4 in a bogie 1; wherein, the primary suspension system The pivot arm node 5 changes the longitudinal stiffness, axial stiffness, torsional stiffness and The deflection stiffness makes the longitudinal stiffness and deflection stiffness of the pivot arm node 5 decrease, reducing the lateral load when the vehicle passes through the curve at high speed. At the same time, by increasing the axial stiffness, the torsional stiffness of the pivot arm node Stiffness is controlled at 11-13KN.mm -1 , the axial stiffness is controlled at 6-8KN.mm -1, so as to reduce the lateral load when the vehicle passes through the curve at high speed, and reduce the bearing wear inside the axle box; at the same time, by changing the structure of the primary vertical stop 6, ...

Embodiment 2

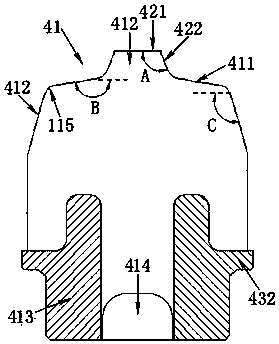

[0071] The structure of the second embodiment is basically the same as that of the first embodiment, except that the joint of the rotating arm is formed by combining two elastic rubber parts with symmetrical structures (as shown in the attached image 3 and 4 shown), including the left metal outer jacket 12 and the left metal inner jacket 11, the left rubber layer 13 is integrally vulcanized between the left metal outer jacket 12 and the left metal inner jacket 11, and the right metal outer jacket 14 and the right metal inner jacket 15, in The right rubber layer 16 is vulcanized as a whole between the right metal outer sleeve 14 and the right metal inner sleeve 15; the inner holes of the left metal inner sleeve 11 and the right metal inner sleeve 15 are respectively arranged as taper holes facing each other, that is, the big end of the taper hole is outside, and the taper hole The small heads of the inner back to back are close together; it is characterized in that the inner d...

Embodiment 3

[0080] Embodiment 3 has basically the same structure as Embodiment 1, except that the support ball joint device includes an upper half support base and a lower half support base, the upper half support base is fixedly connected to the vehicle body frame, and the support ball joint is arranged on Between the upper half support seat and the lower half support seat, the connecting bolts are screwed into the upper half support seat through the lower half support seat, the lower half cover and the upper half cover in sequence, so as to connect and fix the supporting spherical hinge device on the on the body frame.

[0081] The two ends of the rubber layer of the inner sleeve of the bogie jib node are each dug inward with a circle of annular grooves; among them, the groove depth dimension H3 of the small diameter end is controlled at 15~30mm; the groove depth dimension H4 of the large diameter end It is controlled at 10~20mm, and the radial stiffness of the bogie is reduced and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com