Turnover supporting tool of high-pressure heater tube system

A technology of high-pressure heaters and piping systems, applied in hoisting devices, hoisting devices, transportation and packaging, etc., to achieve good support and positioning, and not easy to deform and damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described in detail below in conjunction with specific embodiments and accompanying drawings.

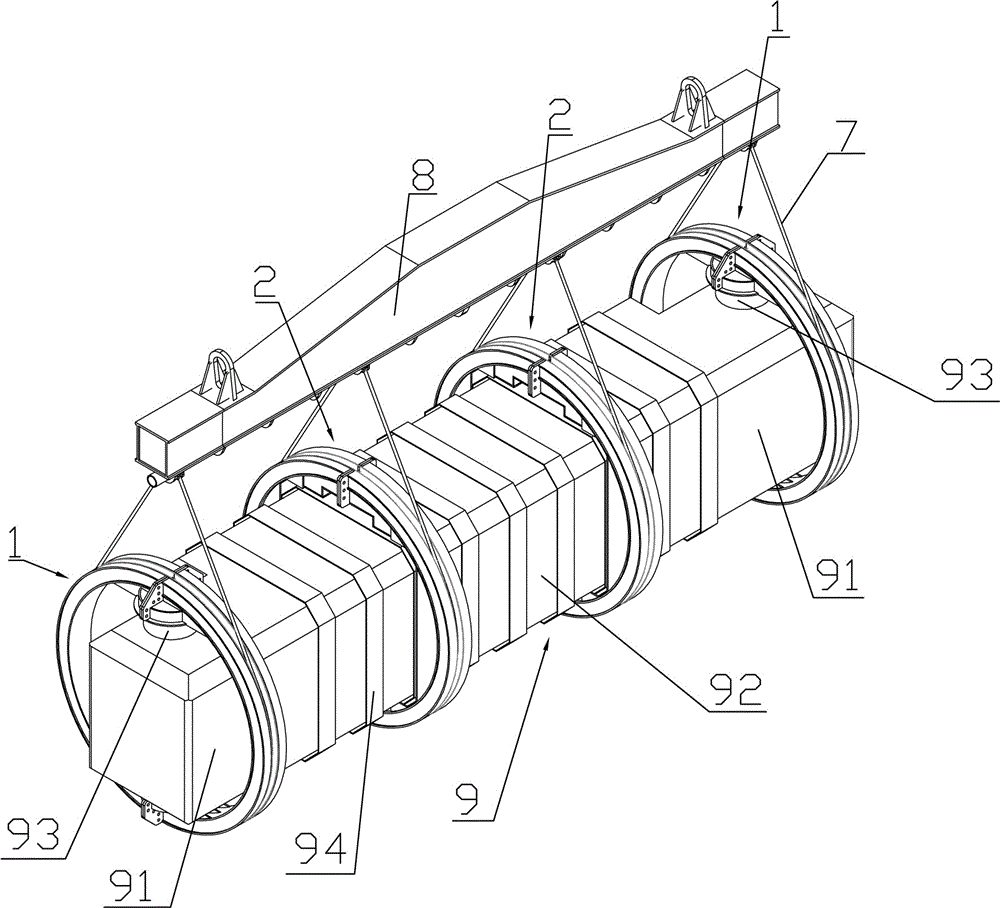

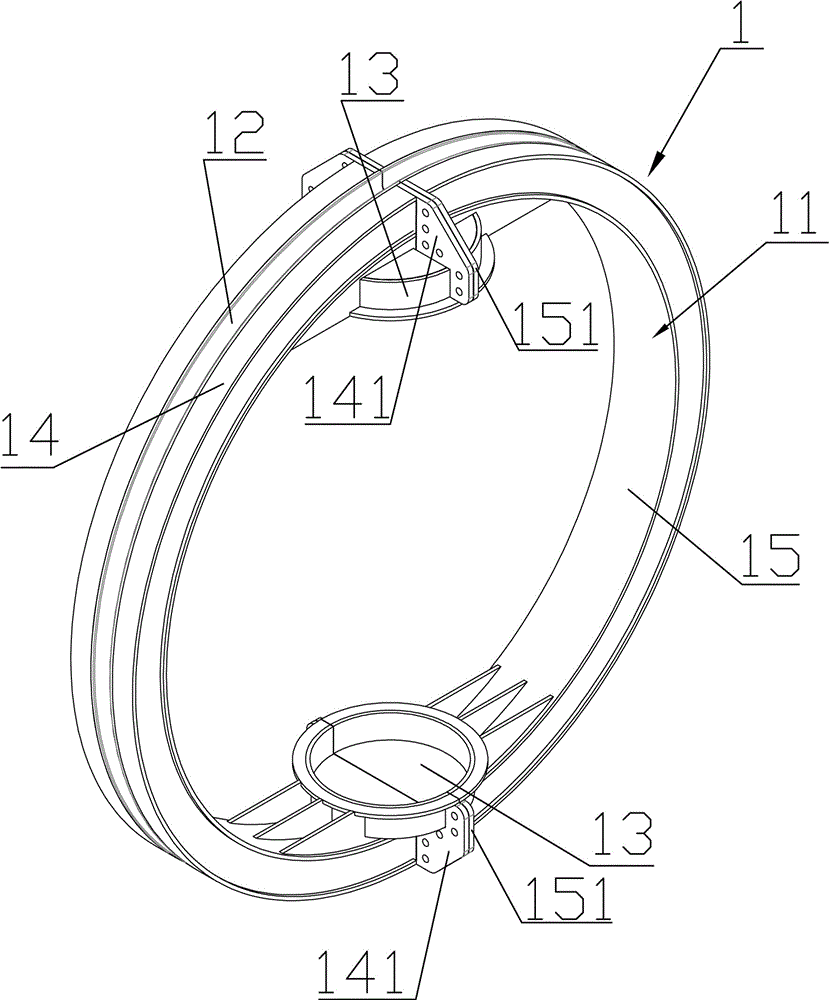

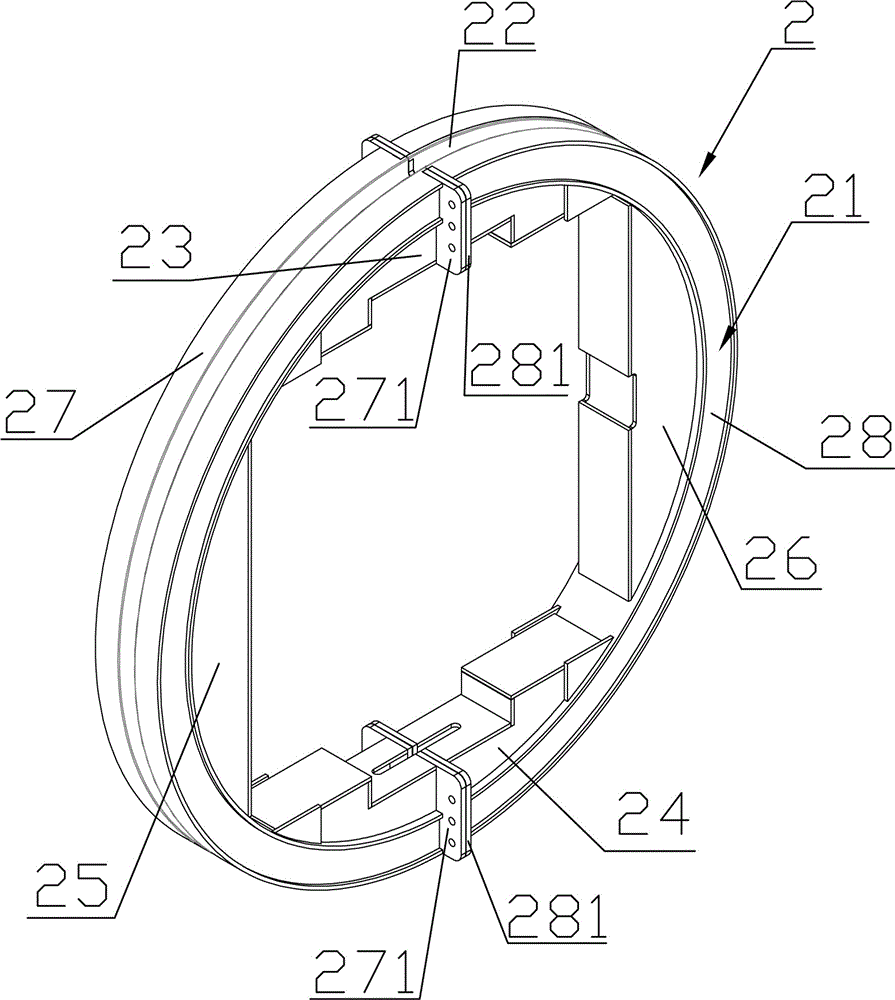

[0012] Such as figure 1 As shown, the flip support tooling of the high-pressure heater piping system includes two header brackets 1 that can respectively position and support the headers 91 at both ends of the piping system 9 and two header supports 1 that can position and support the tube bundles 92 in the piping system 9 Enclosure support 2, such as figure 2 As shown, the structure of the header support 1 includes: a first support ring 11, on the outer surface of the first support ring 11, a circle of first annular grooves 12 capable of accommodating steel wire ropes is arranged, and on the inner circle of the first support ring 11 The upper and lower sides of the upper and lower sides are respectively provided with a positioning cover 13 that can cover the end surface of the header cylinder 93. The first support ring 11 is formed by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com